On Beams with a Round Cross-section, or Vigas

Many old barns and houses make use of floor joists and rafters that were made from locally grown straight tree trunks. Sometimes the builder would flatten one edge of the timber with an adz, so that roofing or flooring could be more easily nailed to it. In Mexico and the Southwest, exposed vigas (beams of round cross-section) are a common and attractive architectural feature.

Owner-builders today sometimes make use of their own home-grown timbers. They can be taken to a sawmill for squaring, they can be milled in the forest with a portable sawmill, or they can be barked and used in their natural round cross-sectional shape.

While this book is mostly concerned with the use of timbers milled on four sides, the author is in no way opposed to the use of viga-type beams, which can be quite beautiful. Here are some tips with regard to their use.

1. Choose sound straight trees for making vigas.

2. Remove the bark. The easiest time to do this is in the spring, when sap is rising. The greasy sap actually makes barking the wood very much easier, as it forms a slippery layer between the bark and the cambium wood layers. Good tools for barking include a pointed mason’s trowel, a straight hoe, or a peeling spud made from any piece of flat stock metal that has an edge sharpened. Barking at the wrong time of the year, such as autumn, may necessitate the use of a drawknife, which is a lot like hard work.

3. For the purpose of judging the strength of a viga, consider its small end as the sectional dimension. Remember the old saying that a chain is only as strong as its weakest link? This principle is often

appropriate with timber framing, where a mortise and tenon joint can actually reduce the shear strength of beams where they join a post. However:

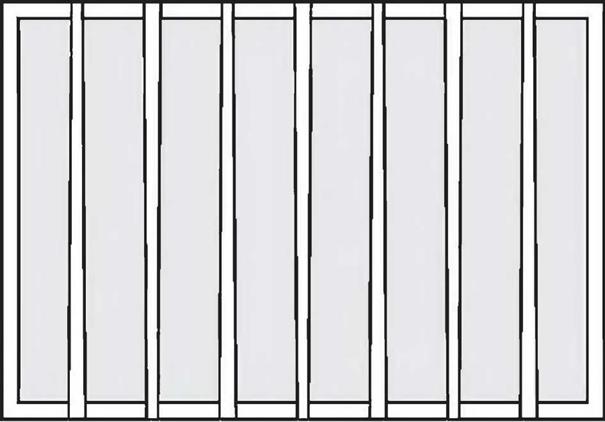

4. For maximum strength with rectilinear structures, alternate large and small ends on parallel rafters or joists, as per Fig. 2.6. This is different from the weakest link analogy, as the entire floor or roof is distributed over several parallel rafters and alternating weak and strong members lends greater strength to the entire structure. Stronger members assist weaker members.

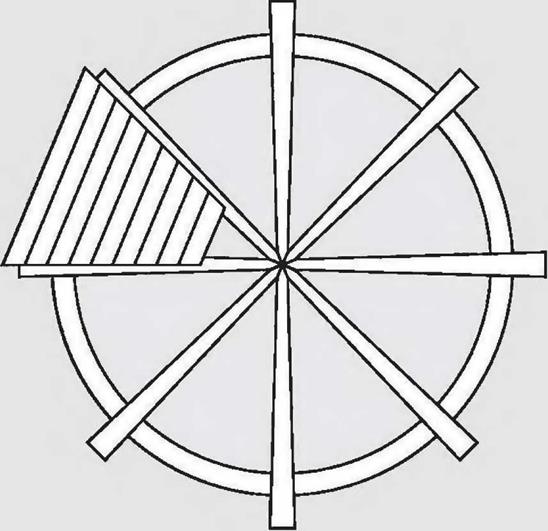

5. With a radial rafter system, where all the rafters or joists head towards the center, as in our round Earthwood house, put all the smaller ends towards the middle, where they are supported by a large post or a post- and-capital, as per Fig. 4.28. The frequency (space between members) is greater towards the center, so the strength there is naturally enhanced. The big ends are placed at the building’s circumference, where they

help to support the greater planking spans and their resultant loads. Fig. 2.7.

Incidentally, for beams with a round cross – section, like vigas, the section modulus is expressed as S = fTd3/32, or, simplifying constants, S = .09818d3. So, for a beam cut from a tree trunk with a small-end diameter of eight inches, we get a section modulus of.09818(8")3, or 50.27 inches cubed. A beam with a square cross-section, common with timber framing, has a section modulus of S = d3/6. So, for a full eight – by-eight, S = (8")3/6 = 85.33 inches cubed. I find it interesting that an 8" diameter log has so much less bending strength than an eight-by-eight timber. Also, the eight-by-eight is "stiffer." See the section on Deflection.

|

Leave a reply