About Metal Fasteners

Several companies manufacture metal fasteners for a variety of wood-to-wood and wood-to-foundation applications. Since 1975, I have done a lot of timber framing without using these fasteners (except for truss plates), and I will share my techniques in these pages. But manufactured metal fasteners can make life easier, the building inspector happier, and improve the strength of the structure, so they are a valuable option. There are hundreds of different connectors available, and, while reading this book is a good introduction, I cannot cover all of the products in this relatively small volume. Therefore, you should also 1) go to your local hardware or building supply store and look at what’s readily available in your area (see Fig. 4.12) and 2) contact the companies by mail or through the Internet and look at their catalogs or web pages. There is an engineered code-compatible connector for practically every imaginable situation.

If there is a downside to these manufactured connectors and fasteners, it is that they are made mostly for lumber of finished dimensions. In the mechanical fastener industry, a four – by-four is almost always 3V2 inches by 3V2 inches and a six-by-six is 5V2 inches by 5У2 inches. However, companies do manufacture full-sized connectors for rough-cut posts, and also some joist hangers for rough-cut material. Simpson Strong-Tie Co, Inc., for example, has joist hangers for all depths (up to 14 inches or 35.6 centimeters) for rough-cut two-bys, four-bys, and six-bys, but not for three – bys and five-bys. One local building supply sells USP joist hangers that will work with full-sized five-by-tens.

Still, over 90 percent of the fasteners in a catalog are for dressed lumber, so you will have to wade carefully through the catalogs to find what you need. You can also call the companies with specific requests, although specialty items will be expensive. Plan ahead for your connectors, so that you have them when you need them. The cost of standard connectors and fasteners is very reasonable, with many simple strap and plate connectors selling for fifty cents or less.

Still, over 90 percent of the fasteners in a catalog are for dressed lumber, so you will have to wade carefully through the catalogs to find what you need. You can also call the companies with specific requests, although specialty items will be expensive. Plan ahead for your connectors, so that you have them when you need them. The cost of standard connectors and fasteners is very reasonable, with many simple strap and plate connectors selling for fifty cents or less.

Another potential downside of galvanized metal fasteners is that they are not particularly attractive. However, they are usually installed where they are not seen, or, at any rate, not seen for very long. Also, Simpson Strong-Tie makes a few heavy (12-gauge) ornamental connectors with textured fiat black paint, including straps, T-straps, right angles, and a variety of heavy joist hangers. These are quite a bit more expensive than the standard fare, but can justify their cost if only a few are needed in exposed locations.

Post supports, for example, can be installed so that the metal parts will be hidden in the thickness of whatever infilling material is chosen. Similarly, right angle connectors, used, for example, where a girt is supported on a post, can be hidden in the infilling.

![]()

First floor joists are almost always hidden, but exposed ceiling joists or roof rafters are not.

First floor joists are almost always hidden, but exposed ceiling joists or roof rafters are not.

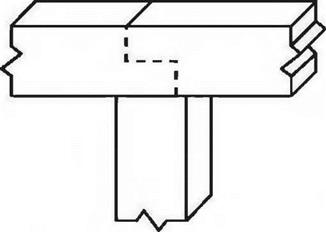

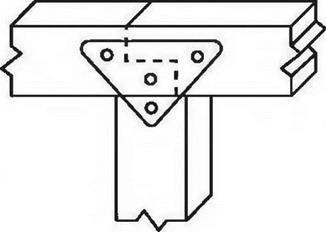

An option to commercially available fasteners is homemade ones, a favorite of many owner-builders. Several examples are shown in this book. Often, home-made connectors for heavy-timbers are made of one- eighth-inch (3.2 millimeter), three – sixteenth-inch (4.8 millimeter), or one-quarter-inch (6.4 millimeter) flat steel stock, which are all available in regular widths, such as 2-inch, 3-inch, 4-inch, 6-inch, etc. When these steel pieces are painted black, they become an attractive part of the structure. See Figs. 4.13 and 4.14a & b. See also Fig. 5.45 on page 138.

The half-lap joint can cut the girders shear strength in half, but the frame in Fig. 4.13 is overbuilt in the first place, and the heavy metal plates would return much of the shear strength to the member in any case.

Larry Schuth of Hilton, New York built a cordwood home within a post-and-beam frame, and told of his adventure in Chapter 17 of my previous book, Cordivood Building: The State of the Art (see Bibliography), which also has a color picture of the finished home. Larry’s foundation consists of two eight-inch block walls laid side by side, in order to provide 16 inches (40.6 centimeters) of bearing for his cordwood. But rather than go “double-wide” with his post system, as Joe Zinni did in Tenino, Washington (see the photo essay Joe’s Rocket Research Landing Pad at the end of this chapter), Larry built a strong frame using just single eight-by-eights as seen in Fig. 4.15.

Incidentally, sometimes plywood makes an effective fastener, particularly as gussets (plates that cover an area where two or more timbers come together), and where they can be used in a hidden application.

Leave a reply