It’s Difficult to Compare U-Factors

The U-factors reported by European window manufacturers—whether given in European units (W/m2^K°) or North American units (Btu/ft2^F°)—are difficult to compare with U-factors reported by North American manufacturers. European and North American laboratories use different protocols to test window U-factors, and most glazing experts agree that European U-factors would look worse if the windows were tested according to NFRC requirements.

|

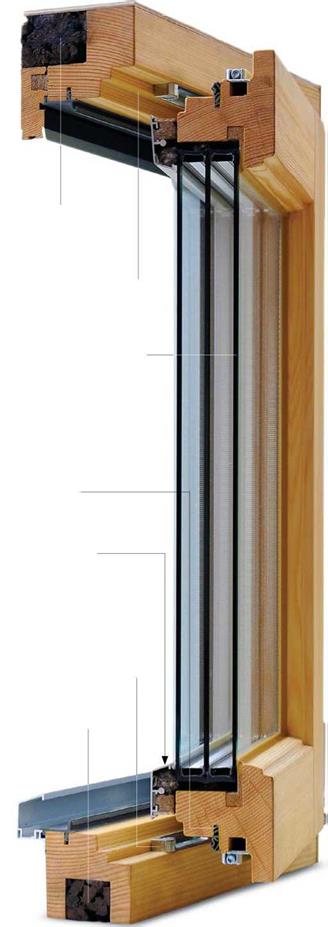

The interior of the frame, — which is made of either fir or spruce, is left exposed. |

|

Zertifikat |

|

Triple glazing with warm-edge spacers is filled with argon or krypton. |

|

U-factor: 0.137 SHGC: 0.53 VT: 0.72 (glass only) |

|

Kerfed-in bulb — weatherstripping |

|

U,0.85 W/(m*K)

|

|

Aluminum cladding increases durability |

|

Locking hardware that’s been compared to that of a bank vault helps to compress extensive weatherstripping to limit air infiltration.—————————— |

|

|

Cork acts as a——– thermal break. |

U. S. distributors of European windows don’t follow a consistent method for reporting U-factors. Some use European metric units, while others report North American U-factors or even R-values. Although the NFRC requires U-factors and SHGC to be based on the performance of the whole window, including the frame, many European manufacturers report U-factor and SHGC numbers that measure the performance of the glazing alone.

There is a straightforward conversion factor for converting a European U-factor in W/m2^K° to a North American U-factor in Btu/ft2^F°: Simply divide by 5.678. Unfortunately, while this method converts the units, it doesn’t account for the fact that the European protocol tests windows of a different size from the size used in North American testing, or for the fact that European windows are tested at different temperatures than required for North American tests.

To appreciate the performance of the windows featured here, it’s helpful to look closely at a typical window made by an American manufacturer. The argon-filled, double – paned window made by Marvin (above) is an example of a unit suitable for houses built to code minimums.

For the most part, the glass in European Passive House windows is quite similar to the glass used in the best Canadian windows: argon – or krypton-filled triple glazing with two low-e coatings and warm-edge spacers. That’s why many energy experts report that the thermal performance of the best European windows is about the same as that of fiberglass-framed, triple-glazed Canadian windows. Katrin Klingenberg, founder of the

U-factor: 0.28 SHGC: 0.25 VT: 0.42 Cost: $670

Passive House Institute US, gives a bottomline analysis: "Our experience has been that the overall performance of the fiberglassframed Canadian and U. S. windows is almost as good as the German Passive House windows if you look at the overall systems design [using Passive House Planning Package software]."

However, European window manufacturers continue to push the performance envelope, and glazing manufacturers are always striving to improve their products. The latest versions of low-U triple glazing from Europe may have a higher SHGC than comparable low-U triple glazing available in North America. According to some window experts, European manufacturers are already selling windows with better insulated frames and glazing with a slightly lower U-factor than any frames or glazing available from North American manufacturers.

Typical European Passive House windows have composite frames, often including a wood lamination on the interior, a core of foam or cork to act as a thermal break, and a weather-resistant exterior cladding of aluminum or rot-resistant wood.

Although the wide frames on European windows reduce the windows’ thermal performance—especially their potential for solar heat gain—compared to narrow-framed

North American fiberglass windows, the thermal breaks incorporated in European frames are usually more effective than those used by North American manufacturers.

North American fiberglass windows, the thermal breaks incorporated in European frames are usually more effective than those used by North American manufacturers.

North American Products Rely on Narrow Frames and Synthetic Materials

Although European triple-glazed windows are well built and attractive, they cost far more than North American windows with similar performance specs. (For an operable triple-glazed casement window measuring 8 sq. ft., you can expect to pay between $400 and $520 for an Inline, Fibertec, or Thermotech® window. A Serious window with Heat Mirror™ glazing will have a lower VT rating, but it will cost about the same—$400 to $560, depending on the glazing chosen.) Windows from Europe also have a long lead time—anywhere from 10 to 12 weeks.

Unlike almost all U. S. manufacturers, Canadian manufacturers of fiberglass windows offer full-thickness (13/s in.) triple-glazing. Even when U. S. manufacturers offer triple glazing, it’s usually thin (1 in. or 7/s in.), low-performance glazing. While Canadian window manufacturers offer both low-solar – gain and high-solar-gain triple glazing, it’s difficult to buy high-solar-gain triple glazing from a U. S. manufacturer.

Canadian fiberglass windows have other attributes that make them more attractive than European offerings. Canadian windows have narrower frames than European windows. Because frames have a lower R-value than a superinsulated wall, narrower frames mean better thermal performance overall. Also, narrow-framed windows allow more light and more solar heat gain than wideframed windows.

When looking for high-performance windows made domestically, you’ll come across the following materials.

The pultruded fiberglass used for the best Canadian window frames is similar to the fiberglass used to make stepladders, only denser and smoother. Even when left unpainted, pultruded fiberglass is extremely durable and weather resistant. Because it has a coefficient of thermal expansion that closely matches that of glass, it’s a much more suitable material for window frames than vinyl.

Heat Mirror glazing has only two panes of glass; the performance of the glazing is improved by one or more stretched plastic films suspended between the two panes. The plastic films create two or three separate air spaces between the inner and outer panes of glass, mimicking the performance of triple or quadruple glazing but with less weight.

The best-known manufacturer of Heat Mirror windows is Serious Materials. Serious offers windows with lower U-factors than any triple-glazed window. Its best-performing operable window (a 1125 series casement or awning window with three plastic films) has a whole-window U-factor of 0.13. The low-U-factor glazing comes with a downside, however: a very low SHGC (0.20) and a very low visible transmittance (0.30). In other words, the windows don’t let in much light or heat. European window manufacturers (and most Passive House builders in the United States) have been reluctant to use Heat Mirror windows due to lingering skepticism about the long-term durability of the plastic films and an unwillingness to accept lower SHGC and VT ratings.

VINYL FRAMES WITH TRIPLE GLAZING

Builders experiencing triple-glazing sticker shock may want to consider a lower-cost option: vinyl windows. Paradigm Windows of Portland, Maine, offers casement windows with foam-injected frames. Paradigm’s best performing krypton-filled triple-glazed casement windows have a whole-window U-factor as low as 0.17. Unfortunately, these

almost all U. S. window manufacturers, Paradigm Windows doesn’t yet offer high-solar – gain triple-glazed products.

High-Performance Windows Don’t Make Sense in All Homes

The high cost of triple-glazed windows is hard to justify unless you’re building a superinsulated house in a cold climate. But once your wall specs reach the R-40 level, triple-glazed windows start to make sense.

A triple-glazed Optiwin tilt-turn window will cost at least $880, while a window from Bieber® will cost almost twice as much. Fortunately, Canadian windows with comparable performance specs cost roughly half the price of an Optiwin window.

Because of their positive latching hardware, casement, awning, and tilt-turn windows always outperform single – or double-hung windows.

![]() Martin Holladay is a contributing editor to Fine Homebuilding.

Martin Holladay is a contributing editor to Fine Homebuilding.

Leave a reply