Is Your Heating System an Energy Beast?

■ BY DAVE YATES

The economy is down, fuel costs are up, and chances are that your heating budget is already busted. You need to do something—but what? Only a few of us are ready to invest in geothermal or solar. The rest of us need to find the answer in the heating system we already have.

For 70% of U. S. households, that system consists of a furnace that forces hot air through ducts; for 17%, it’s a heat pump; and for 11%, it’s a boiler that heats with water or steam radiators. The remaining 2% of homes use wood, coal, geothermal, solar, or other heating methods. When it comes to fuel, 58% of us use gas (either natural or propane), about 35% use electricity, and almost 7% use fuel oil.

Your home might not have the most efficient heating system available, but there’s good news: You can tune up your current system so that it performs better, keeps you more comfortable, and doesn’t put as big of a dent in your wallet. The following can help. Although the topics might seem simple, they’re useful in diagnosing deficiencies. In fact, I usually end up fielding a lot

of these questions from homeowners based on their observations of how their heating system is or isn’t working. Once you know where your system is falling down, it’s possible to boost it (and its efficiency) back up.

Q&A

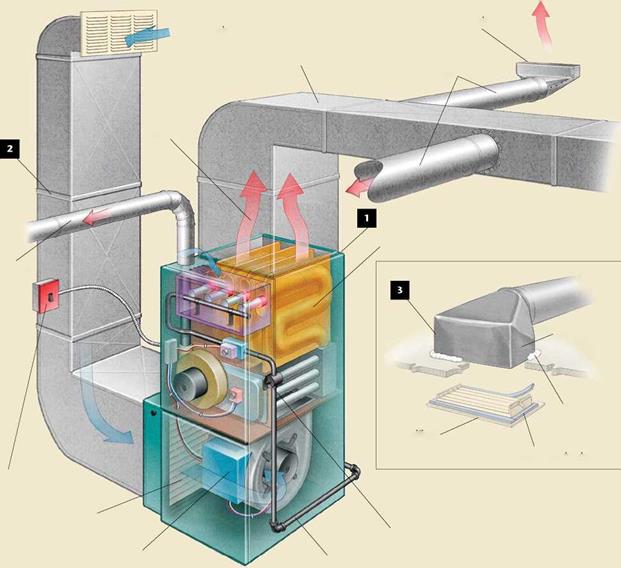

Q: I hear a whistling noise around the blower compartment of my furnace. What is causing the noise? Should I be concerned?

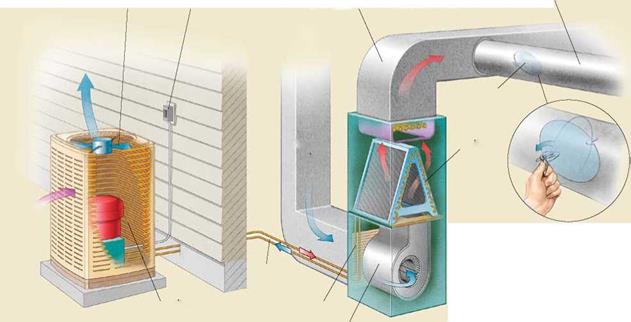

A: You’ re hearing air leakage. All air handlers (any device with a blower, including furnaces, heat pumps, and central air) have two ducts: one for supply, the other for return. I often find considerable air leakage at both connection points. If the blower is located in an unconditioned location (attic, crawlspace, or basement), it is bleeding out heat, or Btu, on the supply side while pulling in unconditioned air that must be warmed (or cooled and dehumidified) on the return side. This energy loss can add 10% or more to your heating and cooling bills.

You can fix these leaks by sealing the connection with sealant and/or top-grade mastic tape rated to withstand the area’s exposure. While you’re at it, check the air handler’s access door, another frequent

source of air leaks. Because the access door must be opened to service the equipment, you want to use only tape or magnetic strips to seal gaps. Other spots to seal include filter slots and openings for wiring. Last but not least, the accessible ductwork should be examined for leaks. Seal them with high – quality tape, mastic, or sealant that’s compatible with the duct material and with exposure to surrounding air temperatures.

|

|

Q: Streaks of dirt are visible around the ceiling registers in our house. What’s causing them?

A: Those streaks are tiny particles of soot blasted across the ceiling by air leaking from around a register that isn’t connected properly. Think of your ceiling as the inner layer of a sandwich. If you had X-ray vision, you’d see the duct boot resting on the attic side of the ceiling with the register below, sandwiching the ceiling between them.

If the boot isn’t firmly attached, you’re heating (or cooling) your attic—typically unconditioned space—which means your energy dollars are being lost to the great outdoors. The same goes for floor registers. In either case, the cure is the same: Remove the register, use a sealant to close the gaps between the boot and the ceiling (or floor), and add foam weatherstripping between the ceiling (or floor) and the register to prevent air leakage.

Furnace Basics

Furnace Basics

Disconnect

switch

Filter box’

Gas shutoff

Blower’

|

|

Q: Our local oil company is offering a $29.95 service special. It seems like a bargain, but does heating equipment need to be serviced every year?

A: Just as people should get an annual physical, all heating equipment should receive an annual checkup to maintain peak performance and to keep the home’s occupants safe. Part of the service is a test for proper combustion using an analyzer that provides CO (carbon monoxide), O2 (excess oxygen), and CO2 (carbon dioxide) levels, as well as net stack (exhaust) temperature. You should ask for a copy of this test, or combustion analysis.

While the internal surfaces of some gas appliances don’t need to be vacuumed (unlike oil units), regular maintenance is particularly important for newer high – efficiency models. Also, in all units, the chimney or venting should be inspected periodically to make sure it’s not obstructed. Dirty heat exchangers in oil burners rob efficiency, which results in increased fuel usage. A layer of soot just Vie in. thick reduces operating efficiency by 10%.

That said, it’s not physically possible to clean and tune up an oil-burning appliance properly for $29.95. Companies offering prices that low often pay technicians a flat rate for each call they make; the more they fit into a day, the more profitable it is for them—at your expense. I often see those furnaces six to eight years later, when they’re malfunctioning. So accept the fact that if it sounds too good to be true, it probably is, and call in a professional technician you can trust at a believable price.

|

■ |

What Should I Expect from a Service Call?

• Preliminary combustion analysis • Chimney inspection • Top of boiler removed and combustion chamber cleaned • Soot vacuumed from all surfaces • Oil filter replaced • Oil-burner nozzle replaced • Reassembly; draft in flue and over burner checked; boiler operation tested

• Final combustion analysis

|

|

Q: Our ductwork is located in the attic. There doesn’t seem to be as much warm air blowing from the registers as there used to be. Is that my imagination?

A: Ductwork that travels through unconditioned spaces (basements, crawlspaces, garages, and attics) needs to be well insulated. Uninsulated ducts waste gobs of energy and create drafts as chilled air spills out of ceiling registers; it’s hard to believe how noticeable this is until you’ve felt it firsthand. Newer codes require R-8 minimum insulation on ducts, but on older flex and duct-board systems, it can be as low as R-2.5. Before you consider more insulation, however, remember that insulation can hide the real problem: air

|

|

|

Insulation helps, too. Once all ducts are air – sealed, use insulation to limit heat loss. Owens Corning makes insulated rigid ducts, insulated flexible duct wrap, and foil-faced insulation that can be used to wrap existing ducts (www. owenscorning. com).

Insulation helps, too. Once all ducts are air – sealed, use insulation to limit heat loss. Owens Corning makes insulated rigid ducts, insulated flexible duct wrap, and foil-faced insulation that can be used to wrap existing ducts (www. owenscorning. com).

Leave a reply