Test Results

There are a number of impressive publications in the technical literature that describe the results of testing antinoise properties of various pavements. (Refer to the Bibliography at the end of this book.)

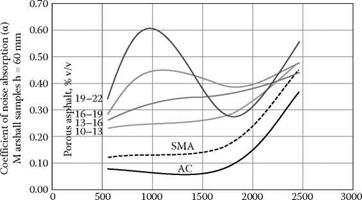

Olszacki (2005) tested the sound-absorbing power of different asphalt surfacing types with diversified void contents. Figure 12.5 shows the relationship between the noise absorption coefficient and sound frequency. It is evident that SMA is characterized by better properties than mixtures of AC, but not as good as porous asphalt with a much higher content of voids, from 10-22% (v/v).

Other research has also stated that pavement noise increases along with an increase in the maximum particle size of the wearing course mixture. Therefore, when antinoise properties are at issue, mixtures SMA 0/5 and 0/8 instead of 0/11 and 0/16 mm are preferred. Generally, the macrotexture of SMA makes it quieter

|

Frequency (Hz) FIGURE 12.5 Impact of asphalt mixture type on noise absorption. (From Olszacki, J., The determination of the water permeability and noise absorption of asphalt concrete used in porous courses [Okreslenie wodoprzepuszczalnosci i dZwiekochlonnosci betonoasfaltow sto – sowanych w nawierzchniach drenujacych], Ph. D. thesis, Kielce University of Technology, Poland, 2005. With permission.) |

than AC by about 1-2 dB(A). When coarse SMA 0/16 is used, an increase in the noise level of about 1 dB(A) is reported (Sandberg, 2001). SMA’s distinctive feature—namely, the grit of 2/4 or 2/5 mm aggregates—makes the pavement noisier, which is why gritting with finer aggregate is recommended. After some time, when the grit been removed by traffic, the SMA noise level will naturally reduce. So the conclusion may be drawn that the SMA antinoise properties change over the service life of the pavement. A site investigation (Schmiedlin and Bischoff, 2002) has proved that a classic SMA pavement is only slightly quieter than classical AC.

Finnish tests of SMA antinoise properties (Valtonen et al., 2002) have pointed out another problem when studded tires are permitted. Testing using the close-proximity (CPX) method was conducted at a speed of 50 km/hr. In spite of the SMA 0/5 mm having the best properties just after laydown (in comparison with SMA 0/8, 0/11, and 0/16), a deterioration in properties due to wear caused by studded tires was found after the first winter of operation (only 1 year of service life). Under these circumstances, the SMA mixture’s resistance to wear by studded tires should have been taken into account. The coarsest SMA gradation is more resistant to studded tire wear, in contradiction to its antinoise properties. Consequently, it has been concluded that SMA 0/8 and SMA 0/11 might be more appropriate than finer SMA 0/5 (in this research, SMA 0/5 has worn 10 times as much as SMA 0/16). In testing done in the United States, SMA 0/12.5 and SMA 0/9.5 mm were compared using the CPX method (Bennert et al., 2004). The results proved the increase in noise at the contact between tires and pavement along with the increase of SMA maximum aggregate size.

Table 12.2 shows the collective comparison of SMA properties with a reference mixture of AC. The new concept of a silent SMA characterized by better properties than classical SMA is presented in Chapter 13.

|

|

Source: From EAPA, Heavy duty surfaces. The arguments for SMA. European Asphalt Pavements Association (EAPA), 1998, With permission. a Negative values indicate an increase in noise level. b Calculated value.

c When the surface is treated with uncoated chippings smaller than 2 mm.

Leave a reply