Skeleton of Coarse Aggregates

In this part of the book we shall deal with the grains within the mix structure that are active in forming a coarse aggregate skeleton. The following significant questions will be answered, too:

• How is a stone matrix asphalt (SMA) mix skeleton formed?

• What does a gap gradation mean?

2.1 DEFINITION OF AN SMA AGGREGATE SKELETON

The notion of an aggregate skeleton of a mixture has a pretty broad meaning. Figure 2.1 shows various types of mineral mixes with different interactions of grains. These range from a sand mix, through mixes where the coarse aggregate particles occupy a more and more substantial share of the volume, and up to a mix consisting entirely of coarse aggregates. The types of aggregates that make up a continuous matrix and form a load-carrying component determine the specific group ranking.

While mixes consisting mainly of an aggregate with sizes up to 2 mm (or 2.36 mm in the United States) (e. g., sand asphalt) are rarely applied, sand-coarse aggregate mixes are within a continuum from mastic asphalt to asphalt concrete. SMA belongs in a coarse aggregates-sand group with porous asphalt, which is the type closest to the straight coarse aggregate type. Mineral mixes with exclusively coarse aggregates make so-called coated macadams, which are seldom used at present.

Now we deal with the first component of an SMA—the skeleton formed of coarse aggregates. Then in Chapter 3 we shall discuss the mastic made of a filler, sand, and binder.

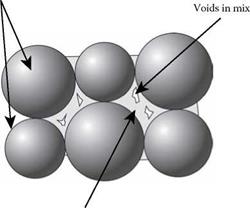

First let us define the term coarse aggregate skeleton. A coarse aggregate skeleton is a structure of grains of suitable size that rest against each other and are mutually interlocked. In Europe, the coarse aggregates are generally taken to be those larger than 2 mm. Following the U. S. option, let us adopt an assumption that a fixed size of 2 mm (2.36 mm in the United States) is not necessarily the lower limit of the coarse aggregate fraction. Why? Well, to meet the structural requirements of a particular grain arrangement (layout), the mechanical resistance of the aggregate blend must be high enough to withstand loads. And this is related to the size of grains, among other factors. So let us agree that a skeleton is made up of adequate size grains but their lower limit is not necessarily equal to 2 mm (2.36 mm). Since the skeleton consists of various coarse aggregate grains, we often use the more universal term coarse aggregate skeleton.

|

|

|

Stone skeleton

|

FIGURE 2.1 Division of mineral mixes into types depending on interactions between sand grains and coarse aggregates. (From van de Ven, M. F.C., Voskuilen, J. L.M., and Tolman, F., The spatial approach of hot mix asphalt. Proceedings of the 6th RILEM Symposium PTEBM’03. Zurich, 2003. With permission.)

Mastic (binder + filler + sand and fine aggregate + stabilizer) |

FIGURE 2.2 Division of SMA into basic components: coarse aggregate (skeleton) and mastic.

To classify all grains of the mineral mix, they may be divided as follows (Figure 2.2):

• Those forming a skeleton (skeleton makers) and carrying loads

• Those filling in the voids in a skeleton and not carrying loads

That division also coincides with the following frequently used terms:

• Active grains (i. e., those forming a skeleton)

• Passive grains (i. e., those filling in voids)

The selection of a sieve to determine a skeleton maker is of great importance for the properties of a newly designed mix. That matter will be treated in detail in Chapter 6.

Leave a reply