PROPER SELECTION OF THE AMOUNT OF A STABILIZER IN A MIX

The procedure for the quantitative selection of a stabilizer in a mix is simple, although it may be a little laborious. One of the draindown testing methods described in Chapter 8 may be adopted here. A series of SMA samples of the same composition should be prepared, but with different quantities of stabilizer. If the procedure is carried out with a proven product (e. g., cellulose fibers), testing may be limited to 0.2%, 0.3%, and 0.4% (m/m). If it is a product that has not yet been used, the testing series ought to cover a somewhat wider range based on the expected behavior (e. g., 0.1%, 0.2%, 0.3%,

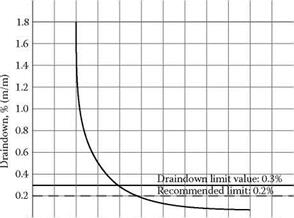

0. 4%, and 0.5% [m/m]). Draindown should be determined for each stabilizer content, and the results should be plotted as shown in Figure 4.10. An important remark—the test temperature should be as close as possible to the real production temperature of the mix in the asphalt plant (see Chapter 8). The amount of stabilizer required for complying with the contract specifications may then be read off the diagram.

|

0 0 0.1 0.2 0.3 0.4 0.5 0.6 Stabilizer (drainage inhibitor) content in SMA, % (m/m) |

FIGuRE 4.10 Example relationship between draindown and stabilizer content used for the selection of an effective content of stabilizer in an SMA mix.

The optimal content of a stabilizer is the one that produces less than 0.3% by mass draindown material (recommended value is less than or equal to 0.2% m/m), unless otherwise specified.

Leave a reply