Preparation of Samples

Preparation of samples for an SMA recipe is conducted according to the Marshall method, with a compaction effort of 2 x 50 blows, or in a gyratory compactor, where the number of rotations are selected in such a manner that the specimen bulk density is similar to results obtained from the Marshall method. While designing SMA with the use of the gyratory compactor, the maximum density of the mix is experimentally established.[42] 7.4.3 Design Method

The applied method of SMA design in the Netherlands belongs to the group of volumetric methods. However, the assumption of a constant amount of binder in a mix makes a significant difference in comparison with other volumetric methods. When any of the final SMA parameters do not comply with the requirements, only the aggregate mix is subject to change. The consecutive stages of design using the Dutch method are discussed next.

The sequence of activities during SMA design is as follows (Jacobs and Voskuilen, 2004; Voskuilen, 2000):

1. Determine the density of materials and execute an aggregate size

analysis.

2. Read a constant binder content (depending on the gradation of the mix)

3. Establish an initial design of the aggregate mix (mix 1).

3.1 Conduct tests of air voids (Vs) in the coarse aggregate fraction (grains greater than or equal to 2 mm) with a gyratory compactor and determine the degree of crushing of the coarse aggregates (analysis of material passing through a 2 mm sieve).

3.2 Adjust the aggregate mix by adding a crushed coarse aggregate fraction to the sand fraction.

3.3 Calculate the volume of mastic for the initially adopted FRs ratio (e. g., -4) using the formula.

V =1 FRs +1 І. V m 100

3.4 Calculate the volumes of the filler and sand in the mix (in the ratio of 65:35 [m/m]) for the previously calculated mastic volume, taking into account the known and constant binder content (e. g., 6.5% [m/m] for SMA 11[43]).

3.5 Calculate the coarse aggregate fraction’s volume in the aggregate mix (the sum of volumes of all constituents should be equal to 100%).

3.6 Convert the estimated volumes of SMA components into mass units.

4. Establish the mass of coarse aggregate fraction in the initial design of an aggregate mix as x% (m/m).

5. Initiate two other variants of the aggregate mix with different contents of the coarse aggregate fraction.

5.1 Mix 2: (x – 2.5%)

5.2 Mix 3: (x + 2.5%)

6. Estimate the sand and filler contents (using the proportion of 65:35 [m/m]) for each of mixes 2 and 3.

7. Prepare SMA Marshall samples (2 x 50 blows) or gyratory compacted samples and determine the air void content in the compacted samples.

8. Determine the relationship between the coarse aggregate fraction content versus the air voids in the SMA.

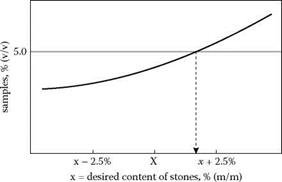

9. Design this coarse aggregate content (directly or through an interpolation of results, see Figure 7.14) so that the content of air voids is in accordance with the requirements presented next.

10. Estimate the FRs ratio for the design mix.

|

FIGURE 7.14 Example of the design coarse-aggregate fraction content based on the content of voids; x = desired content of stones, % (m/m). (From Voskuilen, J. L.M., Ideas for a volumetric mix design method for Stone Mastic Asphalt. Proceedings of the 6th International Conference Durable and Safe Road Pavements, Kielce [Poland], 2000. With permission.) |

The requirements for air voids in compacted SMA 0/11 samples, applied in the Netherlands, are as follows:

• Type 1—for low-volume traffic

• Marshall hammer 2 x 50: 4.0% air voids

• Gyratory compactor: 3.0% air voids

• Type 2—for heavy traffic

• Marshall hammer 2 x 50: 5.0% air voids

• Gyratory compactor: 4.0% air voids

Note: the relationship between air voids obtained from the Marshall method (an impact method) and those obtained from a gyratory compactor should not be interpreted as the difference -1%, because the air void content obtained in samples from the gyratory compactor largely depends on the adopted number of rotations and the angle of rotation of the gyratory compactor. Therefore air void content is not the same in every case.

Leave a reply