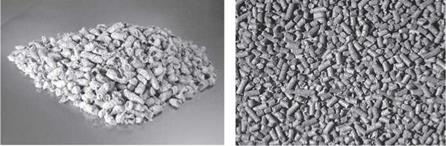

Pelletized Loose Fibers

Loose fibers may be pressed into pellets to keep the fibers together without binding agents. Their shape makes metering of the SMA mix during production easier. Pelletized fibers are formed into different shapes; one example is presented in Figure 4.5. Automatic loading with pneumatic feeders is also possible and easy. The pellets are usually supplied in large packages (big-bags) and stored in silos. All other features of loose fibers remain unchanged.

When performing tests of SMA mixtures in a laboratory, pelletized fibers may be treated without any special preparations. A mechanical mixer is usually not required;

|

FIGURE 4.5 An example of pellets—loose formed fibers. (Photo courtesy of J. Rettenmaier & Sohne GmbH + Co. KG, Germany.) |

|

(a) (b)

FIGURE 4.6 Examples of granulated fibers (a) made of waste paper with wax coating (Photo courtesy of Excel Industries Ltd., U. K.) and (b) made of cellulose with binder coating. (Photo courtesy of J. Rettenmaier and Sohne GmbH + Co. KG, Germany.) |

however, in the case of very dense pellets, it is better to use one to ensure that the pellets are broken up and thoroughly mixed.

Leave a reply