Kjellbase

Colored asphalt surfacing is an aesthetically pleasing option. Colored wearing courses can also be executed with fine-graded SMAs (Blazejowski and Styk, 2000) using special synthetic (colorless) binders. Besides their aesthetic appeal, colored surfacing can also be used to mark pedestrian crossings or other safety-related features.

When making colored SMA, it is important to remember to carefully clean the asphalt plant, mixer, and silos, removing “black” mix remains. Loose fibers, specifically those containing no binder additives and bright aggregates, should be applied.

The strong mineral skeleton applied in SMA has attracted some followers. After all, nothing stands in the way of using similar mixes in intermediate courses or base layers. Kjellbase makes such a mix. The concept, drawn on the “real SMA” idea, came into being in the beginning of 1997, when it was created by Kjell Sardal and S. Gouw. The first trial section was placed in 1997 (Sluer, 2001, 2002; Sluer et al., undated). In fact, Kjellbase is a 0/25 mm gap-graded mix. Now let us have a look at

a

a

a

’K "e3

CD

a

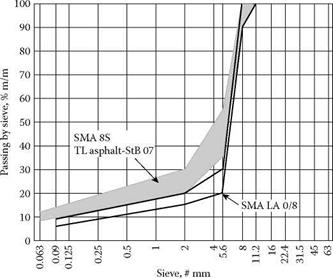

Figure 13.7, which depicts the grading curve of the Kjellbase mix. The gap grading between the 2 mm and 8 mm sieves is clearly visible.

Kjellbase consists of the following (Sluer et al., undated):

• 79% chippings of 8/11 mm, 11/16 mm, and 16/22 mm

• 15% crushed sand

• 6% filler

• 5% modified binder

A small content of fine aggregates (made of only about 5-6% filler and about 15-17% sand fraction) leads to a high void content. Relatively high binder contents close the mix structure, leaving up to 5% (v/v) air voids in the compacted pavement. Since the mix has a large quantity of binder, a mastic stabilizer (e. g., fibers) is required.

Some problems may occur in the laboratory when selecting the right method for the evaluation of mixes of that type. The inventors of the Kjellbase mix concept have estimated that the triaxial compression test may be the proper method.

To summarize the information on Kjellbase, the mineral skeleton of the mix (shown in Figure 2.4.b) is similar to the vision of Figure 2.5. The increased quantity of binder and lower contents of voids in the Kjellbase layer, compared with those of conventional base layers, improves fatigue durability. Thus the mineral skeleton gives that course a higher resistance to permanent deformation.

Leave a reply