Fluctuations in Batching of Components

SMA mixtures are very susceptible to overbatching of the binder quantity during production. When this occurs, an extra amount of binder appearing in a mixture is followed by the rapid decrease of mastic consistency and a change in the volume ratios of the entire SMA. Moreover the risk of binder or mastic draindown becomes much higher.

The strength of SMA is founded on its mineral skeleton. So the properties of SMA are dependent on the gradation and, consequently, are extremely susceptible to the shifting of the gradation curve. As discussed in Chapter 6, we should consider the impact of the change of coarse aggregate content on the breakpoint (BP) sieve. Another way to express that concept is that a substantial change in the content of the largest coarse aggregates causes such significant changes to the volume relations of a mixture that they can greatly diminish an SMA’s strengths.

9.3.5 Systems of Batching Stabilizers

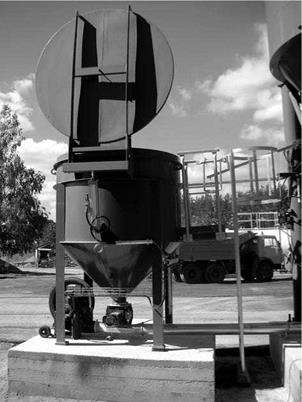

Modern asphalt plants are equipped with integrated silos—delivering and weighing systems mostly designed for granulated or pelletized stabilizers. These stabilizers are stored in silos and then transferred to the scales, proportioned by weight or by volume and blown by compressed air into the pugmill (Figure 9.7). In older plants,

|

FIGURE 9.7 A system for batching granulated fibers into mixing plants. The photograph shows an open silo for granulates ready for loading. (Photo courtesy of Bartosz Wojczakowski.) |

more or less sophisticated batching methods (i. e., proportioning by weight or by volume) are applied to weigh out or measure out a batch of granulated or loose fibers directly into the pugmill (Figure 9.8).

Automatic batching devices for nongranulated (loose fibers) are rare. Bags of loose fibers are emptied through a special charging box into the pugmill (Figure 9.9) or directly through an opening in the upper part of the pugmill’s cover.

|

FIGURE 9.8 Manual proportioning control of a granulated stabilizer directly into the pugmill. (Photo courtesy of Bartosz Wojczakowski.) |

|

FIGURE 9.9 Manual charging box with a motor-driven chute. (Photo courtesy of Bartosz Wojczakowski.) |

When there are no bins for stabilizer, an effective solution may be the direct delivery of granulated cellulose fibers from a tanker into the pugmill.

Leave a reply