Dry-Rodded Method

The dry-rodded method has been standardized in AASHTO T 19-00, where its thorough description has been included. It is recommended to perform two tests per sample and use the average value. The following gives a short outline of the equipment used and the modus operandi.

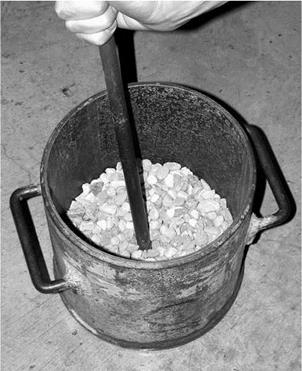

The equipment needed includes a balance, a steel tamping rod (rammer), a cylindrical metal measure, a shovel, glass calibration plate (Figure 7.4), and grease or thick glycerin. The sample of aggregate is dried in an oven to a constant mass. The sample should be about 125-200% of an amount that fits in the container. The cylindrical measure is calibrated by determining the volume using water and the glass plate (Figures 7.5 and 7.6); water-density corrective coefficients in relation to the temperature should be taken into account.

The test is performed as follows: [31] [32]

3.

|

Having completed tamping the second layer of aggregate, fill the container with aggregate to overflowing and continue tamping down as previously described.

4. Even out the aggregate using your fingers or scrape away any excess aggregate with a rod so that protruding coarse particles will compensate for any gaps between them (Figure 7.8).

5. Determine the mass of the compacted aggregate by weighing the measure with aggregate and weighing it empty.

6. Calculations

• Calculate the bulk density of an aggregate according to the formula

G –

V

M = Bulk density of the coarse aggregate, kg/m3 G = Mass of a cylindrical measure and aggregate, kg T = Mass of a cylindrical measure, kg V = Volume of a cylindrical measure, m3 [33]

(Gca-y w)-M

G – Y

ca w

-100% (v/v)

|

|

|

|

|

|

M = Bulk density of a coarse aggregate in the dry-rodded condition, kg/m3 Gca = Bulk specific gravity (dry basis) of a coarse aggregate according to AASHTO T85 = GsbD

Yw = Density of water, kg/m3

Leave a reply