Application of the Method during Production Control

Subsequent to the design of the recipe and its approval, it is time for the production of an SMA mix. Production control using the Dutch method takes into account the same factors that have been used during SMA design (job mix formula [JMF]).

The properties of some elements are naturally changeable; this particularly applies to the aggregate gradation, particle shape, and resistance to crushing.

As noted earlier, designing an SMA using the Dutch method is based on optimizing the coarse-aggregate content in order to obtain the selected air void content in compacted samples of the SMA. So if the gradation of the supplied coarse aggregate changes during production of the SMA in an asphalt plant, then the SMA volumetric parameters change accordingly. Therefore the factory production control (FPC) should include examining the amount of air voids in the coarse aggregate fraction as used in the SMA design. Each new delivery of coarse aggregates should undergo such tests. The results should be compared with corresponding results of testing the materials used in the SMA design. If the difference in the air void volume is greater than 1.5% (v/v), an adjustment must be made to the design in accordance with the principles put forward in Figure 7.15.

How can we make good use of Figure 7.15? Let us fix the following values of a mix: [44]

|

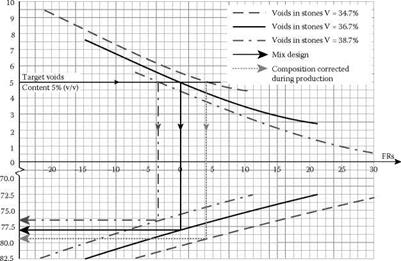

FIGURE 7.15 Graph showing the relationship between the contents of coarse aggregate fractions and air voids applied to the adjustments of mixes when producing SMAs. Note: FRs = Filling ratio stone skeleton. (From Voskuilen, J. L.M., Jacobs, M. M.J., and van Bochove, G. G., Proceedings of the 3rd Eurasphalt & Eurobitume Congress Vienna 2004— Paper 326, 1802. With permission.) |

Let us assume that the properties of new deliveries of aggregates have altered slightly and are marked by a different content of air voids. To maintain the fixed volumetric relationships in the mix under these circumstances, the content of the coarse-aggregate fraction in the SMA design must be changed. Thus we test the new delivery of the coarse-aggregate fraction in a gyratory compactor,* being sure to test not only one single fraction but the entire newly composed material larger than 2 mm. Let us examine two different types of results of this testing:

• Case 1: the content of air voids in the new compacted coarse-aggregate fraction amounts to 34.7% (v/v) (i. e., 2% [v/v] less than in the design).

• Case 2: the content of air voids in the new compacted coarse-aggregate fraction amounts to 38.7% (v/v) (i. e., 2% [v/v] more than in the design).

Whether we deal with the Case 1 or Case 2, the air voids should equal 5% (v/v) of the SMA mix. So let us have a look at Figure 7.15. We can read the instructions on how the content of coarse aggregate fraction in the aggregate mix should be adjusted for the given contents (34.7% and 38.7%) of air voids in the coarse aggregate fractions and air voids in SMA (5.0%). Consequently we find: [45]

• Case 1: the content of air voids in the compacted chipping fraction amounts to 34.7% (v/v), so the coarse aggregate content should be increased to approximately 79.5% (m/m).

• Case 2: the content of air voids in the compacted chipping fraction amounts to 38.7% (v/v), so the coarse aggregate content should be decreased to approximately 76.5% (m/m).

Adjustments to the mix make sense. If there are fewer air voids in the coarse aggregate fraction (particles are packed better in a volume unit), it is necessary to increase the coarse aggregate content (“to open” the mix) in order to retain the 5% of air voids in the SMA. If the coarse aggregate mix is more open after compaction than during design, the quantity in the mix should be reduced (it is necessary “to close” the mix). As we can see, this is the same principle that may be applied to adjust two fillers with different contents of air voids according to Rigden.

Leave a reply