ANTIsKID properties

Antiskid features of wearing courses of asphalt surfacing are described in terms of the friction coefficient, which depends on the micro-texture of the aggregate and the macro-texture of the placed mixture (Gardziejczyk and Wasilewska, 2003). As this property is very important, the range of available publications on the topic at issue is quite broad (Gardziejczyk, 2002; German DAV Report, 2001; Huschek, 2004; Jordens et al., 1999).

Different pavement qualities, in relation to the speed of vehicles, have a decisive impact on antiskid properties (Hunter, 1994). At low speeds, polishing resistance has a decisive impact, hence the durable microtexture of the aggregate surfaces is significant; in this instance the polished stone value (PSV) can be used as a selective index for evaluating an aggregate’s resistance to polishing. At high speeds, the macrotexture depth of the wearing course has a decisive impact; the presence of small channels around aggregate particles on the surface enables water discharge, preventing the formation of a hydroplaning effect (skidding layer).

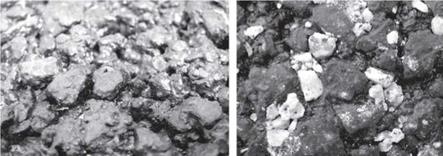

The SMA macrotexture depth depends on the maximum aggregate size in the mixture and the design of the mix (e. g., the level of filling voids among coarse aggregates on the surface of a course with mastic); see Figure 12.6.

|

(a) (b)

FIGURE 12.6 SMA macrotexture before opening to traffic: (a) nongritted and (b) gritted. (Photo courtesy of Krzysztof Blazejowski.) |

Leave a reply