Working with DWV Materials

As mentioned earlier, DWVstands for drainage, waste, and venting. ABS and PVC plastic pipe are by far the most common DWV materials, although cast-iron is still specified where sound suppression is important. Plastic pipe is strong, the most corrosion resistant of any DWV pipe; is easy to cut and assemble, using special solvent – based cements; is light enough for one person to handle; is reasonably priced; and is extremely slick inside, which ensures a good flow of wastes. It’s by far the favorite DWV material of amateur plumbers—and many pros. But there are few disadvantages. Many codes prohibit using plastic pipe on exteriors because of durability and UV degradation issues, and if you don’t spread the cement evenly or allow it to cure before stressing the joints, plastic can leak.

Cast iron is relatively corrosion resistant, though it will rust in time (decades); and its mass deadens the sound of running water. Though it’s heavy to work with, it is still specified by many professionals for high-end jobs, where codes allow pipes on building exteriors, and where codes require cast-iron in multistory buildings. Ever since no-hub couplings replaced lead and oakum, cast iron has been easier to connect, but it still takes skill and strength to cut cleanly and support adequately. Consequently, it’s rarely installed by amateur plumbers. Professionally

|

DWV Fitting Sampler |

|

|

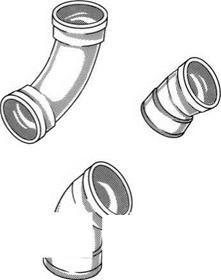

ELBOWS |

TEES OR TEE FITTINGS |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

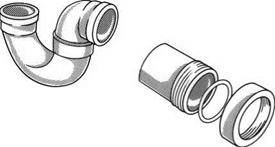

The fittings shown are ABS plastic, but their shapes are essentially the same as those of copper and cast-iron DWV fittings of the same name. Drain fittings-such as the long-sweep ell, the combo and the sanitary tee-turn gradually so wastes can flow freely, without clogging. Whereas vent fittings have tighter turning radii because they carry only air. Finally, street fittings have one hubless end that fits directly into the hub of another fitting, which is useful when space is tight.

|

installed cast-iron systems cost, on average,

30 percent to 50 percent more than plastic pipe installations.

Copper DWV pipe is installed mostly on jobs with bottomless budgets. Copper is lightweight, durable, and undeniably handsome. Because its walls are relatively thin, copper DWV pipe is sometimes specified where there are tight turns. However, copper costs two to three times as much as a plastic DWV installation, and it’s less corrosion resistant. Compared to cast iron, copper’s thin walls don’t suppress sound nearly as well.

Cut ABS or PVC pipe with a plastic-pipe saw and a miter box, or with a wide-roll pipe cutter. If you use a cutter, gradually tighten its cutting wheel after each revolution. Whatever tool you use to cut the pipe, use a utility knife, a rounded file, or a deburring tool to clean off burrs before sanding the cut lightly with emery paper. Use a clean cloth to wipe off any grit.

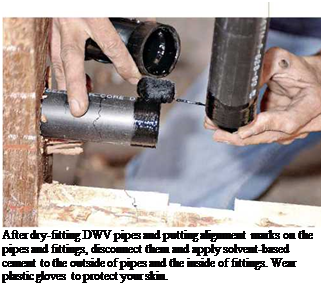

Dry-fit the pipes and fittings before cementing them together. Dry-fitting allows you to determine the exact direction you want the fitting to point, as well as the depth of the pipe’s seat in the fitting. Pipe cement sets so quickly that there’s no time to fine-tune fitting locations. Use a grease pencil or a builder’s crayon to draw alignment marks on the pipe and the fitting; a yellow or white grease pencil works well on black ABS pipe.

Here, two horizontal ABS lavatory drains meet at a figure-5 fitting, also called a doublecombo. An ABS vent rises out the fitting’s top hub, while the drain hub connects to a cast – iron stack via a no-hub coupling. A riser clamp supports the bottom of the cast-iron pipe, and steel nail plates protect the ABS.

(See "Pipe Fitting,” on p. 273). Then take apart the dry-fit pieces and apply the cement.

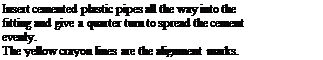

Apply plastic-pipe primer to the outside of the pipe and to the inside of the fitting. Then, using the cement applicator, apply a generous amount of solvent-based cement to the outside of the pipe and the inside of the fitting hub. Immediately insert the pipe into the fitting so that it seats completely. Then turn the fitting (or the pipe) a quarter turn in one direction only—stop when the alignment marks meet. When you are finished, the joint should have an even bead of cement all around. Allow the joint to set completely before putting pressure on it.

One-coat, no-primer plastic-pipe cements are new to the market: They seem promising but as yet are unproven for the long haul. Research them carefully before you commit.

To the inexperienced eye, all cast iron looks the same, but it’s not. If you lightly rap most cast iron with a rubberized tool handle, you’ll hear a muffled thud; old "light iron,” however, will reverberate somewhat, with a higher, tinny tone. If you suspect that you have light iron, which was widely installed in the northeastern United States till the 1940s, hire a plumber to assess and possibly cut it for you. If you try to cut light iron with a conventional snap cutter, the pipe may crush and collapse.

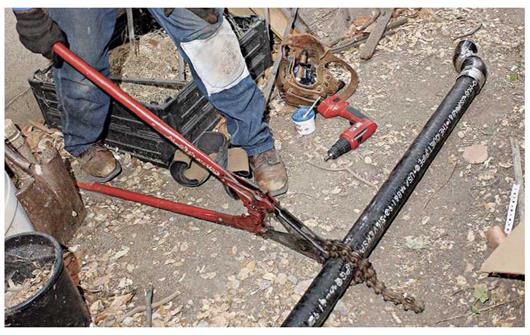

To cut into cast iron to extend a DWV system or replace a corroded fitting, rent a snap cutter. Many cast-iron joints are hubbed, in which a straight pipe end fits into the flared hub. But increasingly, sections of straight pipe are joined

|

Leave a reply