Working with Copper Water-Supply Pipe

This section focuses on installing rigid copper water pipe: It’s strong, easily worked, approved by virtually all codes, and represents nearly 90 percent of residential installations. That noted, you should also consider reading about PEX flexible tubing on p. 279.

If you divide fittings into a few categories, their many names start to make sense. Because they do similar things, supply-pipe and DWV fittings often share names.

Fittings join pipes. The simplest fitting is a coupling, which joins two straight lengths of pipe. A reducing coupling joins different size pipes. A repair coupling has no internal stop midway, so it can slide all the way onto a pipe, then slide back over a new piece of pipe inserted to repair a damaged section. A union is a coupling you can disconnect.

Fittings change direction. The most common directional fitting is a 90°elbow, also known simply as a 90 or an ell. For a more gradual turn, use a 45°elbow, also called a 45 or a Vs bend. A street ell is a 90° elbow with one hubless end, which can fit directly into another fitting’s hub. Ditto, a street 45.

Tees join three pipes. Tees (also spelled T’s) allow you to run branch pipes to individual fixtures or fixture groups. Reducing tees accept different size pipes. If you want to sound like a pro, "read a tee” by noting its run (length) dimension first (in inches), then its branch leg. If both ends of the run are the same size, mention that number only once, as in % by h. But if two legs of a tee reduce, cite all three of the tee’s dimensions, for example: a % by h by h.

Adapters join different types of pipe. A

sweat/male adapter has a soldered end and a

► Get a work permit and a copy of current plumbing codes from your local building department. Follow the codes closely; they’re there

to protect you.

► Get a tetanus shot before you start, and dress for dirty work.

► Wear protective eyewear when using power tools, chiseling, soldering, and striking with hammers—in short, for most plumbing tasks. Wear heavy gloves when handling drainpipe and disposable plastic gloves when working with solvent – based cements or soldering. Wear a respirator mask (not a mere dust mask) when soldering or working around existing soil pipes; P100 filters are the standard protection.

► Use only cordless power tools when cutting into supply pipe. If a power tool shorts out in that situation, it could be fatal. О Before cutting into finish surfaces, shut off the electrical power to nearby outlets, and test with a voltage tester,

as shown on p.235, to be sure power is really off.

► Ensure good ventilation when joining pipes because heated solder and solvent-based cements give off noxious fumes. Make sure you have adequate lighting.

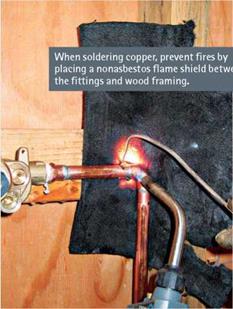

► When soldering joints in place, place a nonasbestos flame shield behind the fittings to avoid igniting the wood framing. Have a plant spritzer, filled with water, on hand to dampen the wood if you must solder fittings close to framing; make sure there’s a fire extinguisher on site.

Molten flux or solder can burn you, so be careful.

► When connecting to existing DWV pipes, plan the task carefully. Flush pipes with clean water beforehand and have parts ready so that you can close things up as soon as possible. To avoid weakening nearby joints, be sure to support pipes before cutting them.

► Be fastidious about washing well after handling contaminated waste pipes and chemicals.

► If you smell gas in a home, stop working: Running equipment or doing soldering could spark an explosion. If you can quickly locate the gas shutoff valve outside, shut it off. In any event, clear everyone from the house at once and call the local gas utility.

|

|

![]()

Leave a reply