Wall-to-Wall Carpeting

Basically, there are two types of wall-to-wall carpeting. Conventional carpeting is laid over a separate rubber or foam padding and must be stretched and attached to tackless strips around the perimeter of the room. Cushion-backed carpeting, which has foam bonded to its backing, doesn’t need to be stretched—it’s usually glued down—so it’s generally easier to install. However, it must be destroyed to remove it. Consequently, better-quality carpeting is almost always conventional, and that’s the focus here.

Carpeting doesn’t ask much of subflooring, which can be slightly irregular as long as it is dry, solid, and adequately sized (58-in. plywood is typical). Carpeting can be installed over existing wood, tile, resilient flooring, or concrete floors; but check the manufacturer’s recommendations regarding subgrade installations, acceptable gaps in the substrate, padding thickness and type, and so on. Don’t scrimp on padding; buy the densest foam or heaviest rubber padding you can.

You can rent most of the specialized tools. To install conventional carpeting you’ll need the following:

► A power stretcher stretches carpeting taut across a room, so it can be secured to tackless strips along opposite walls. Crossroom stretching eliminates sags in the middle of a room. You simply add and adjust stretcher sections to extend the tool.

► A knee-kicker is used in tandem with the power stretcher to lift the carpet edges onto strips, to stretch the carpet in a closet, or to draw the seams closer together before you hot-glue them.

► The stair tool drives carpeting into the spaces between tackless strips and walls and between stair risers and treads.

► A seam iron heats the hot-melt carpet seam tape that joins the carpet sections.

► The row runner, or row-running knife, cuts between the rows of loop-pile carpeting. Many installers use a large, flat-bladed screwdriver to separate the rows first.

► An edge trimmer trims the carpet edges so they can be tucked behind tackless strips; under baseboards; or under transition pieces such as metal carpet doors, which are used in doorways or where dissimilar flooring materials meet.

► Seam rollers can be either star wheeled (spiked) or smooth; they press the carpet edges onto the hot-melt seam tape to ensure a strong bond. Use a smooth roller for cut-pile carpets and a star roller for loop-pile carpets.

► Miscellaneous tools include a utility knife with extra blades, aviation snips to cut tackless strips, a hammer, a stapler if you’re applying padding over plywood, a notched trowel if you’re installing padding over concrete, heavy shears, a chalkline, a tape measure, and a metal straightedge to guide utility-knife cuts.

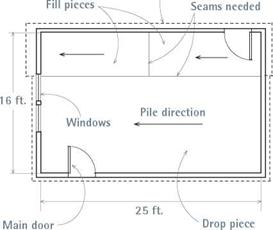

Carpeting comes on factory rolls whose standard width is 12 ft.; a handful of carpet manufacturers offer widths of 13 ft. 6 in. or 15-ft. Plan on covering most of the room with a large piece of carpet 12 ft. wide, then covering the remaining spaces with smaller pieces joined to the large piece with hot-melt seam tape. Professional installers call the full-width piece of carpet the drop; the smaller pieces are called the fill. Joining carpet seams is time consuming so choose a layout that minimizes seams.

Start by measuring the room’s width and length at several points; then make a sketch of the room on a piece of graph paper. A 14 in. to 1 ft. scale is a good size to work with. On the sketch, include closets, alcoves, base cabinets, floor registers or radiators, stairs, doorways, and so on. Also note the location of doors and windows, particularly the main entrance into the room. Carpet pile should slant toward the main entrance, so that a person entering the room looks into the carpet pile.

Carpet seams and edges must be trimmed, so

factor that into your estimate. Add 3 in. for seamed edges, and allow 6 in. extra for each carpet edge that runs along a wall. Stair carpet pile

An ideal layout minimizes waste and seams, positions seams away from traffic, and orients carpet pile so that someone entering through the main entrance looks into the pile. Carpet comes in 12 ft.-wide rolls (also called bolts), so 41 RF (running feet) of carpet would allow enough extra for trimming edges in this 16 ft. by 25 ft. room.

nail the strips or to stretch carpeting behind or under such obstacles. To anchor carpet edges in doorways, you can use a metal carpet bar, which has angled barbs like a tackless strip, as shown in "Carpet Transitions,” on the facing page. Or you can install a hardwood threshold to provide a clean edge to butt the carpet to, after first anchoring it to a tackless strip, or folding the carpet under about 1 in. and nailing down that hem.

Leave a reply