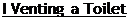

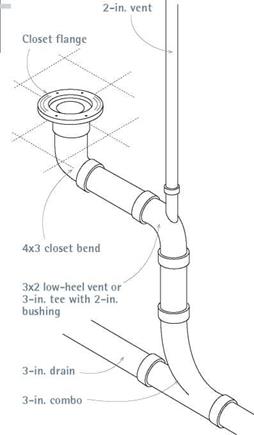

Venting Options

Until you expose the framing and actually run the pipe, it’s difficult to know exactly how things will fit together—especially vents. Because correct venting is crucial, the section discusses several venting options to consider. But first, here are a few terms to keep straight: A stack is a vertical pipe. If the stack carries wastes, it’s a soil stack. If the stack admits air and never carries water, it’s a vent stack.

Most of the venting options described next are examples of dry venting, in which a vent stack never serves as a drain for another fixture. But there are hybrids; for example, if a vent stack occasionally drains fixtures above it, it is a wet vent. Wet vents must never carry soil wastes, and many local codes prohibit all wet venting. But when it’s legal and the vent is one pipe-size larger than normal to ensure a good flow, wet venting can be safe and cost effective because it requires fewer fittings and less pipe.

|

|

No-hub couplings (also known as banded couplings, band-seal couplings, and hubless connectors) consist of an inner neoprene sleeve, which fits over the pipe ends or fittings, and an outer corrugated metal shield, which is drawn tight by a stainless-steel band clamp. No-hub couplings are widely used to join cast-iron pipe and no-hub fittings in new construction, but they are also invaluable to renovators.

For example, if you want to add a plastic shower drain to a cast-iron stack, no-hub couplings can accept either a cast-iron or a plastic no-hub fitting and seal it tightly to the pipe ends once you’ve cut into the stack. (Support both sides of the section to be cut out so it can’t shift during cutting and weaken other joints.)

When joining DWV pipes of different materials, use specialized transition couplings whose neoprene sleeves are sized for incoming pipes with different outside diameters, such as the coupling used to join 2-in. copper and 2-in. cast iron, shown in the photo at left.

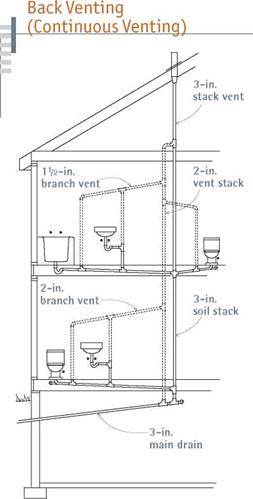

Back venting (also known as continuous venting), is the dry-venting method shown below, and it’s acceptable to even the strictest codes. All the fixtures in the drawing have a branch vent. In a typical installation, the trap arm of, say, a lavatory empties into the middle leg of a sanitary tee. The branch drain descends from the lower leg; the branch vent from the upper. When a branch vent takes off from a relatively horizontal section of drainpipe, the angle at which it departs is crucial. It may go straight up, or it may leave at a 45° angle, to work around an obstruction. But it must never exit from the side of a drainpipe:

If it did, it could become clogged with waste.

|

|

In this illustration of back venting, all fixtures have a dry branch vent—that is, no vent ever carries water. The fixtures on the first floor require a 2-in. branch vent because the toilet’s 3-in. drain needs more incoming air to equalize its large waste flow.

Maximum Distance: Trap Arm to Vent*

TRAP ARM MAXIUM DISTANCE DIAMETER (in.) TO VENT

|

M |

2 ft. 6 in. |

|

M |

3 ft. 6 in. |

|

2 |

5 ft. |

|

3 |

6 ft. |

|

4 |

10 ft. |

|

* Also maximum distance of stack-vented fixture trap arm to stack, based on calculations found in the UPC, T10-1. |

Branch vents must rise to a height of at least 42 in. above the floor before beginning their horizontal run to the vent stack. This measurement adds a safety margin of 6 in. above the height of the highest fixture (such as a sink set at 36 in.), so there is no danger of waste flowing into the vent. Since branch vents run to a vent stack, they should maintain an upward pitch of at least!4 in. per foot; although the UPC allows a vent to be level if it is 6 in. above the flood rim of a fixture.

Clustering plumbing fixtures around a central stack is probably the oldest method of venting. In the early days of indoor plumbing, plumbers noticed that fixtures near the stack retained the water in their traps; whereas those (unvented) that were at a distance did not. You can vent three bathroom fixtures (lavatory, tub, and toilet) off a 3-in. stack vent, without additional branch vents—if you detail it correctly, as shown in "Stack Venting,” above right.

Note: When stack venting, never place a toilet above the other fixtures on the stack: Its greater discharge could break the water seals in the traps of small-dimension pipes. If you must add fixtures below those already stack vented, add (or extend) vent stacks and branch vents. The maximum allowable distance from stack-vented fixtures to the soil stack depends on the size of the pipe serving a particular fixture; see "Maximum Distance: Trap Arm to Vent,” above.

|

|

Leave a reply