TILE AND SLATE ROOFS

Tile and slate are relatively brittle, expensive, and easily damaged if you don’t know what you’re doing. And they’re slippery when wet. In most cases, hire a pro to make repairs.

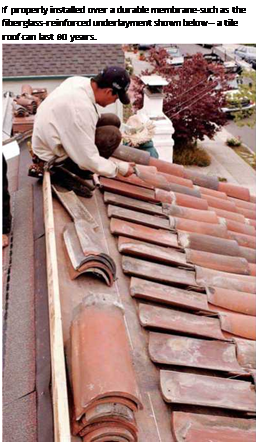

Tile and slate are so durable that they often outlast the underlayment and fasteners. So when repairing or replacing these roofs, prolong the life of the installation by using heavy under – layment (30-lb. building paper or a self-adhering bituminous membrane), copper attachers, and copper flashing. Although these materials are expensive, if the roof lasts upward of 60 years without leaking, it’s money well spent.

Roof tiles weigh about three times as much as asphalt shingles. So if you’re thinking of installing a new type of tile or tiling a roof for the first time, have a structural engineer evaluate your situation. Your roof framing may need bolstering to support the additional load.

Tiles are available as two-piece, mission-barrel tiles; as one-piece, low-profile concrete tiles; and as flat-shake tiles, which mimic wood shakes. Tiles overlap to direct rain into tile channels. Traditionally, tiles were set without nails on wood battens or skip-sheathing. But today they are commonly nailed to plywood sheathing, especially if the roof pitch is 5-in-12 or steeper. Two-piece mission tiles are nailed in two manners: Trough tiles are nailed directly to sheathing. Cap tiles, which sit atop trough tiles, are attached to intervening copper wires nailed to the roof.

Tiles are available as two-piece, mission-barrel tiles; as one-piece, low-profile concrete tiles; and as flat-shake tiles, which mimic wood shakes. Tiles overlap to direct rain into tile channels. Traditionally, tiles were set without nails on wood battens or skip-sheathing. But today they are commonly nailed to plywood sheathing, especially if the roof pitch is 5-in-12 or steeper. Two-piece mission tiles are nailed in two manners: Trough tiles are nailed directly to sheathing. Cap tiles, which sit atop trough tiles, are attached to intervening copper wires nailed to the roof.

Slate roofs are most often damaged by tree limbs. You can usually make repairs safely if the damage is along an edge and hence reachable without requiring that you walk on the roof. If you note a number of missing slates and concomitant rust stains on the roof, the nails may be rusting through, creating an extremely dangerous situation. Call a slate specialist at once.

To repair incidental damage, buy a slate hook. Work the head of the tool up under the damaged piece until the tool’s hooked head catches a nail shank. Then strike the handle of the tool with a hammer to cut through the nail shank. When both shanks are severed, slide out the damaged slate, being careful not to disturb adjacent pieces.

Once the damaged slate’s on the ground, transfer its dimensions onto a replacement slate. Then rent a tile-cutting saw to cut the new piece, wearing goggles. Or ask a tile dealer to cut the piece for you. Ideally, the new piece should be the same size as the one it’s replacing, but old nail shanks may prevent sliding a full-size replacement piece into place. In this case, trim the replacement piece further.

That done, align the bottom edge of the replacement slate to others in the course. Predrill two nail holes, each one 1 in. from the edge and about 1 in. below the course above; you’ll probably be drilling through two layers of slate, so take it slow. (A cordless drill is ideal for this task.) Size the drill bit just slightly larger than the thickness of the nail shank. Because this pair of nails won’t be covered by the slate above, caulk all holes with urethane before inserting nails. Drive the nails down just snug and no more, so you don’t split the slate.

Although metal roofs tend to be quite durable, nail maintenance is key to their longevity. Most leaks occur when wind and ice lift the sheeting and pop nails up.

At least once a year and after major storms, study the roof with binoculars, and nail down any pop-ups. For extra security, put a dab of urethane caulk beneath nail heads. (Although roofing cement works too, it would be unsightly.) If popped nails seem loose, upsize the nail or use a screw.

To avoid galvanic-action corrosion, use nails or screws that are compatible with the roof metal. By the way, nail or screw metal roofing only at the raised crests, not in troughs where the water runs.

If the roofing is rusted but serviceable, use a wire brush on the surface to remove the rust and paint on an elastomeric roof coating, such as Gacoflex® acrylic latex. An elastomeric coating is necessary because metal expands and contracts. Incidentally, such coatings can also extend the life of metal gutters.

If the roofing is rusted but serviceable, use a wire brush on the surface to remove the rust and paint on an elastomeric roof coating, such as Gacoflex® acrylic latex. An elastomeric coating is necessary because metal expands and contracts. Incidentally, such coatings can also extend the life of metal gutters.

Leave a reply