SPRAY-PAINTING EQUIPMENT

In recent years, spray-painting equipment has become much easier to operate and maintain. Spraying is most appropriate where you’ve gota whole house to paint or where surfaces are ornate (gingerbread trim), multifaceted (shingles), textured (stucco), or otherwise difficult to cover with a brush or roller. Spraying is also smarter when you need to apply numerous thin, even applications, as on cabinet doors. The key to successful spray-painting, as with any painting, is thorough prep work. That is, begin by correcting moisture problems, removing loose paint and dirt, caulking and filling holes and gaps, and priming unfinished substrates.

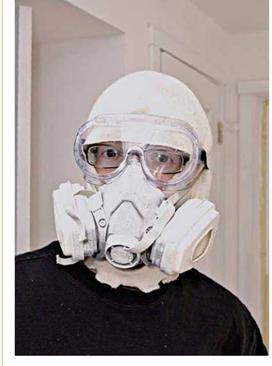

Spray-painting safety begins with a respirator mask with two replaceable organic-vapor filters. If you’ll be spraying exteriors, a half-face mask should be adequate. For interiors, where paint concentrations build up quickly, wear a full-face respirator mask, gloves, a spray sock to keep paint mist off your head, and coveralls taped at the wrists and ankles. The greater the concentration of paint mist, the sooner filters will clog and cease filtering. Review additional comments on mask safety on p. 436.

Spraying equipment typically consists of a pump to pull paint out of a bucket, a connecting hose, and a spray gun. At this writing, you can

![]()

|

|

|

The right protective gear can keep paint mist off your skin and out of your lungs. This includes a respirator mask with replaceable vapor-filters, as well as a “spray sock" over your head, safety goggles, and disposable gloves. |

rent contractor-grade equipment for $50 to $75 per day, or buy a quality setup for $1,200 to $1,500.

Compact, efficient airless sprayers have largely replaced the earlier units with their bulky com

pressors, pressurized paint pots, and two hoses. Today, single-hose, airless sprayers deliver paint at up to 2000 lb. of pressure, atomizing paint at the spray tip. High-volume airless sprayers can apply coatings of varying viscosity, from thin to extra-heavy.

High-volume, low-pressure (HVLP) sprayers are usually recommended for novices because the lower pressure makes spray patterns easier to control and less likely to overspray. The disadvantage of HVLP sprayers is the risk of applying insufficient paint, resulting in a uneven, “orange – peel” paint texture.

Spray tips control paint volume and pattern, or fan. Fixed-size tips are coded with three-digit numbers: The first digit (2-9) indicates in inches half the width of the paint fan when you hold the tip 1 ft. from the surface being painted. The next two digits (00-99) indicate the size of the tip opening in thousandths of an inch. So a no. 518 tip will spray a 10-in.-wide fan (at 1 ft. away) and has an 0.018-in. opening.

A few manufacturers make adjustable spray tips, but they’re a specialty item. If, for example, you’ll be at the top of a 20-ft. ladder, need several different spray patterns, and don’t feel like climbing down the ladder to change tips, use an adjustable tip. But 99 percent of the time, fixed – size tips are the way to go: they cost less and maintain a precise aperture longer.

Leave a reply