SETTING BEDS

Tile can be set on a variety of setting beds. Keep in mind that the substrate below the setting bed must be securely attached to the framing members. That assembly must be thick and stable enough to support loads with minimal deflection (J4(> of the span). And when used in damp or wet areas, it needs to remain unaffected by sustained exposure to water.

Mortar beds. Where walls aren’t plumb, floors aren’t flat, and corners aren’t square, mortar beds are usually the best setting bed. They can easily be screeded level or plumb to create a flat surface. In fact, a mortar bed is the only practical choice if you’re tiling the sloping floors of a shower stall. But few novices have enough skill to float a mortar bed. If your surfaces are badly out

|

Applying mortar beds takes strength and a lot of skill. After installing a curing membrane and attaching wire mesh, you must carefully mix and trowel the mortar on, level or plumb float strips, and screed off excess mortar till the bed is uniformly flat. Then, after it has set a bit, use a wood float to roughen its surface slightly, which improves the adhesion for the thinset to follow |

of whack and you’re not experienced in floating mud, hire a pro for this job.

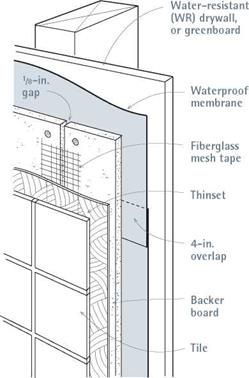

Backer board. If walls and floors are reasonably plumb and level, backer board is a durable setting bed for wet and dry installations. It’s stable, unaffected by moisture, and easily cut and attached. Backer board is also called cementitious backer units (CBUs), HardiBacker®, Durock®, and WonderBoard—the last three being popular brands. These products feature a cement-based core, reinforced by fiberglass mesh or integral fibers. Because there’s considerable variation among brands, always consult product literature for details on installation.

Glass-mat gypsum board. This board (one brand is DensShield®) has a water-resistant core and heat-cured acrylic coating. It’s not as rugged as backer board, but it’s an acceptable setting bed in tub surrounds and other light-duty wet areas. Don’t confuse this product with drywall. Glass – mat gypsum board is specifically designed to be a tile backer.

Unpainted drywall. Drywall is an acceptable setting bed where walls stay dry. Caution: Never bond tile directly to drywall in damp or wet installations. Water-resistant (WR) drywall (or greenboard) is an acceptable substrate in damp or wet installations only when it is covered with a waterproofing membrane and then a mortar bed or backer board.

Tile applied directly to drywall in wet installations invariably fails sooner or later, often because people showering bump the walls, compressing the drywalls gypsum core. No longer supported evenly by the core, the grout loosens, water enters and soaks the paper, and—all too often—the framing rots.

Exterior-grade plywood. It’s usually a mistake to use plywood, even exterior grade, as a setting bed. Exposed to moisture, plywood tends to swell and delaminate. If you must use it as a setting bed for floor or countertop installations, be sure to cover it with a continuous waterproofing membrane; the base should be at least 1 Ys-in. thick (for example, h-in. plywood underlayment laminated to a %-in. plywood subfloor). On walls, %-in. plywood is the minimum. Never use particleboard, oriented strand board (OSB), or interior-grade plywood as setting beds.

Self-leveling compounds. Self-leveling compounds (SLCs), such as LevelQuik®, have many of the virtues of a mortar bed but require few of the skills needed to float one. Basically, SLCs are fortified mortar powders mixed thin and poured onto out-of-level floors. With a small amount of troweling, they spread across the floor and, within minutes, start to set. Just 2 hours later you’ve got a hard, almost perfectly level mortar-setting bed ready to tile.

That’s the short list of common setting beds. For other materials see "Odd or Problematic Setting Beds,” on p. 392.

Once you’ve chosen a suitable setting bed for your wet or dry installation, choose a compatible adhesive. Adhesives vary greatly from brand to brand, so again, always follow the manufacturer’s mixing and application instructions exactly.

There are three major groups of adhesives: mastics, which come ready mixed; thinset adhesives, which are cementitious powders generally mixed on-site just before setting the tile; and epoxy thin – sets that, like most epoxies, require your mixing a hardener and a resin.

Organic mastics are the least expensive of the three adhesive options. Because they come premixed, they’re the most convenient option, but they’re also the weakest. They are okay for attaching tiles to dry counters or walls—over dry- wall, for example—but they’re inappropriate

where there’s water, heavy use, or heat. Mastics just don’t have the strength of thinsets.

Mastics require a nearly flat setting bed. That is, when they are applied thickly to fill voids, they neither cure completely nor bond thoroughly. Mastic cleans up well with water or solvent if you remove the excess material at once. Opened containers don’t keep well, so throw away any leftover mastic after you’ve set the tiles.

Thinsets have great bonding and compressive strength. Being cement based, they bond best with mortar beds or backer board but are appropriate for virtually all setting-bed materials. Thinsets are also used to laminate rigid setting beds to substrates in order to create an inflexible substructure for tiling. (Construction adhesive is also used in such laminations, but it is flexible and so doesn’t achieve the rigidity of a thinset lamination.)

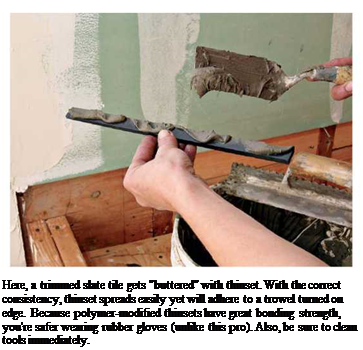

Despite the cement ingredients they have in common, thinsets vary widely, depending on their additives. Water-based thinsets are the weakest of the group, although they are generally stronger than mastics. Latex – and acrylic-based thinsets (also known as polymer-modified thin – sets) are strong and somewhat water resistant and are, all in all, the best choice for bonding tile to backer board, mortar beds, SLCs, drywall, and concrete slabs. And they’re a close second for bonding almost everything else.

Most thinsets are mixed from powder. After mixing, they have a "bucket life” of about 2 hours. After being troweled onto a setting bed, they start to set in 15 minutes to 20 minutes.

Epoxy thinsets have excellent compressive and tensile strengths. They also bond well and yet retain flexibility when cured. After drying, they are unaffected by moisture and so are suitable for all situations and substrates. There’s a catch, of course: Epoxies are four or five times more expensive than other thinsets and quite temperamental. You must mix the liquid resins and hardeners in exact proportions with the dry ingredients. Setting times are similarly exacting. If directions say 20 minutes, you can set your watch by them. Above all, clean up epoxy before it sets; some types sponge clean with water, others with solvents.

Grout is a specialized mortar that seals the joints between tiles. Most grouts contain sand, cement, and a coloring agent. Grout may also contain additives to stabilize color, increase water and stain resistance and increase strength and flexibility. Most grouts and premixed additives are sold as a powder, which is subsequently mixed with liquid and allowed to stand (or slake) for

|

|

This tub surround would be sufficiently rigid without the WR drywall. But installers frequently add a drywall layer to build up the wall thickness when they’ll be using bullnose edge trim.

10 minutes before final stirring to the correct consistency.

Use sandless grout for joints narrower than ‘/ in. Use sanded grout for joints Z in. and wider.

Most tile suppliers carry grout in hundreds of colors. Whatever the color, remember that the greater the contrast between grout and tile, the more obvious the joints and workmanship.

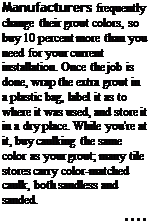

Tile, grout, and many setting beds are unaffected by water. But they are porous, so water can migrate through them, potentially damaging plywood substrates or wood framing. To prevent such damage in damp or wet areas, install a waterproofing membrane first. Even areas that are normally dry, such as entryways, should have a modest building – paper membrane if the floors will be subject to wet mopping and dripping umbrellas.

For walls above the water line in wet areas and for countertops subjected to occasional water, a 15-lb. building-paper membrane is standard, but installing a 60-minute stucco paper

(which is impermeable for 60 minutes) makes sense. It’s stronger, less likely to tear, and more water resistant. When installing such membranes, overlap the lower courses and vertical seams of paper by 4 in. Although some builders recommend 4-mil. polyethylene as a waterproofing membrane, stucco paper has one big advantage: Unlike plastic, it is semipermeable. Therefore, it allows water to escape should any get behind the barrier.

Below the water line, such as in a shower pan, you need to protect wood substructure with an impervious membrane. Thus most shower pans are lined with sheet rubber, such as 30-mil, fiber-reinforced chlorinated polyethylene (CPE), whose seams are overlapped and chemically bonded with a solvent. Of course, you don’t want to puncture CPE shower-pan membranes with screws or nails. Instead, roll the membrane onto a fresh layer of latex thinset adhesive, and cover it with a mortar bed.

Note: The comments in this section are generalizations. Follow the manufacturer’s installation instructions for specific adhesives, membranes, and setting-bed materials.

Leave a reply