Roof Flashing

Because underlayment directs water away from sheathing, it’s technically flashing, too. More often, however, roof flashing refers to sheet metal that protects building seams or edges from water penetration or diverts water around pipes, chimneys, dormers, and so on. Metal flashing is widely used because it’s durable and relatively easy to cut and shape. Always replace old flashing when installing a new roof.

Various sheet materials are suitable for flashing. Unformed, they come in sheets 10 ft. long or in rolls of varying lengths, widths, and gauges. Copper is the longest lasting and most expensive. Lead is the most malleable but is also the most vulnerable to tears and punctures. Galvanized steel ranks second in longevity, but it’s so rigid that you should buy it preshaped or rent a metalbending brake to use on site. Lightweight aluminum is commonly shaped on site and is a good trade-off in expense and durability. There’s also painted steel flashing, in case you don’t like the glare of bare metal.

When installing flashing, use the fewest nails possible and avoid nailing in the center of a flashing channel, where water runs. If possible, always position nails so they can be overlapped by roofing above. Where you must leave nail heads exposed—say, when installing skylight flashing or wall cap-flashing—put urethane caulk under the nail heads before driving them down or use gasketed roofing nails.

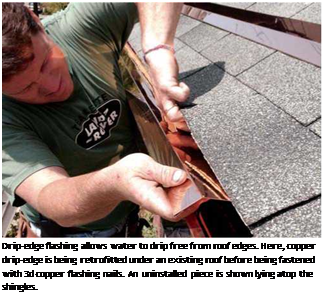

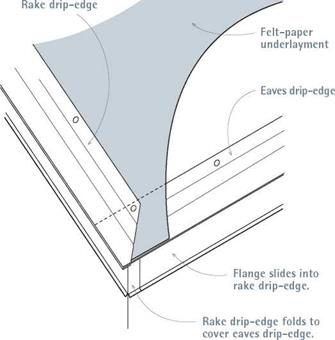

You want water to drip free from roof edges, rather than being drawn by capillary action back up under shingles or sheathing. Drip-edge also covers and protects sheathing edges from gutter splashback and ice dams along the eaves and gives rake edges a clean, finished look. The

ACTION

A number of metals, if paired, will corrode one another in a process called galvanic action. To be safe, use nails or clips that are the same metal as the flashing you install. Because water is an electrolyte, any moisture present will increase corrosion. The following metals make up a group known as the electrolytic sequence.

|

|

When you pair up materials, the metal with the lower number will corrode faster. If you must pair two different metals, you can retard galvanic action by insulating between the metals with a layer of heavy (30-lb.) building paper.

crimped edge of drip-edge flashing also resists bending and thus supports overhanging shingles.

crimped edge of drip-edge flashing also resists bending and thus supports overhanging shingles.

Drip-edge is sold in varying widths and comes in an L-shape or a lopsided T-shape. Install drip – edge along the eaves first, nailing it directly to sheathing, using 4d big-head roofing nails. Space nails every 18 in. or so. Underlayment along the eaves thus overlaps the drip-edges. Along the rake edges of a roof, install underlayment before applying rake drip-edge. In the corners, where rake edges meet eaves, run the rake drip-edge over the eaves drip-edge. Slitting the vertical leg of the rake drip-edge makes it easier for you to bend it over the leg of the eaves drip-edge.

In general, drip-edge flashing 6 in. wide or wider is better than narrower flashing because it enables you to nail well back from the edge of the flashing—always desirable.

Leave a reply