Replacement Windows

If existing sashes have deteriorated and you’d like to avoid the major headache of ripping out existing frames, casing, finish surfaces, and siding, then replacement windows can be a cost-effective solution. These units come encased in frames, which you insert into existing wood frames, after removing the old sashes and pulling the parting beads so that old jambs are reasonably flat. Just cut the sash cords and leave old sash weights in the wall.

Start by measuring the existing window frames carefully, because replacement units fit snugly inside them. Old frames are frequently out of square, even if their jambs are parallel. Thus, in addition to measuring height and width, note which way a frame leans, so you can order the biggest rectangle that will fit into that opening. To install most replacement units, apply a 3/s-in. bead of siliconized acrylic caulk along the inside faces of the interior or exterior window stops and across the sill in line with those stops. Set the new window in bottom first, tilt it up into place, and then press its vinyl frame into the caulking so there’s a good seal. There’s little shimming; many models have adjustable screw jacks that hold side jambs tight to the opening. Use a mild expanding polyurethane foam to seal the gaps around the unit.

Admittedly, these units are something of a compromise. If existing frames and casings are parallel but not plumb, replacement windows are commonly installed slightly off-plumb. Replacement sashes tend to be narrower than old-fashioned wood ones, so there’s also an aesthetic compromise. That noted, vinyl – or Fiberglas®-clad replacement units are typically one-half the cost of custom-milled wood sashes, require little maintenance, and cut drafts and energy costs dramatically. Their color range is limited—white—but you can paint Fiberglas. Aluminum-clad units come in dozens of colors but are the most expensive option, and salty coastal air will eventually corrode the metal.

![]()

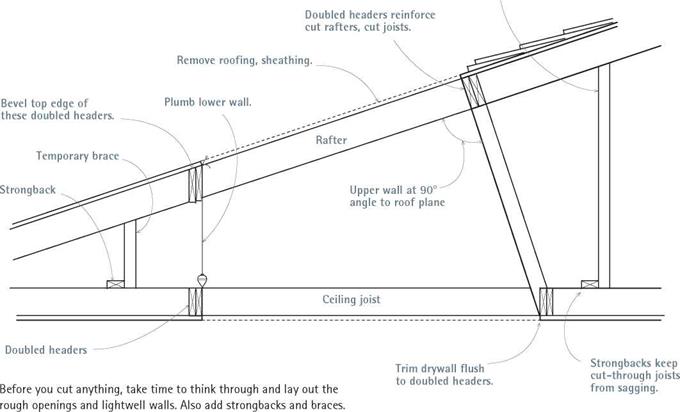

Folks often order skylights larger than they need to be. Keep in mind that even the smallest unit brightens a room greatly. Moreover, much of the light gain comes from reflections off the sides of the lightwell (or lightshaft), which is why wells are usually painted white. You can increase the amount of light markedly by flaring out the sides of the well. If you need more light than one narrow skylight will yield, consider “ganging” several, side by side, in adjacent rafter bays. Smaller skylights are easier to frame out, and the fewer rafters you disturb, the better.

Most skylights are sized incrementally to fit between rafters spaced 16 in. or 24 in. on center. Thus skylights routinely come in 24-in., 32-in., and 48-in. widths. Skylights 32 in. wide are the most popular size because you need to cut only one rafter to accommodate the unit. Velux®, for example, has several models whose inside curb dimensions are 30’/г in. wide—the same distance between rafters spaced 16-in. on center, if one rafter in between is removed. Aligning the inner faces of skylight curbs and rafters also makes installing drywall much easier. Attached to the

roof sheathing with L-shaped mounting brackets, the sides of Velux units sit right over rafters.

This section provides general guidance related to the framing procedures shown in the photos. Usually, it doesn’t matter whether you cut ceiling joists or rafters first, as long as they’re adequately supported. Some pros prefer to frame out the lightwell completely before opening the roof; whereas others place the skylight first and measure down from that.

Insulation. Remove the ceiling insulation. Then disconnect and cap any wires and pipes that will need to be rerouted around the opening. (Use a voltage tester to be sure the power’s off.) Where possible, work from a stepladder rather than sitting on ceiling joists; that way, you’ll be less likely to crack the finish ceiling. The job will go faster if one worker on a ladder measures carefully and calls out measurements for headers, trimmers, lightwell studs, and the like to a second worker on the floor, who does the cutting.

Before cutting ceiling joists, support them

with a strongback, which is a piece of dimension

Temporary braces support cut-through rafter.

Leave a reply