Rain Gutters

Gutters direct water away from the house, preventing water from collecting next to the foundation and thereby possibly undermining it. The two most common gutter profiles are half-round and K-style, in which the gutter has a squared-off back and an ogee front. For appearance’s sake, try to match the profile of new gutters to old.

To clear water adequately, gutters must be sized properly and cleared of leaves and debris twice a year—in spring and in fall. Your lumberyard probably has elaborate gutter-sizing charts based on regional rainfall, roof square footage, and pitch. But you might remedy chronically overflowing downspouts simply by upsizing the gutters from a standard 5-in. width to a 6-in. model and installing larger downspouts. To keep

|

|

Begin any gutter installation by checking the slope of roof edges and trim and then measuring the areas to receive gutters. Typically, gutters extend beyond the roof section ‘h in. on each end. As you reconnoiter, consider where downspouts will be least obtrusive.

|

|

roof runoff from running behind gutters and rotting fascia, extend the roof drip-edge flashing so it overhangs the gutter.

If gutters are spaced too far from the roof edge or slope away from the drip-edge, you can place an L-shaped piece of metal flashing over the back of the gutter and tuck its upper edge up under the drip-edge. (Notch that flashing so it fits around the roof hangers.) Some К-style gutters also come with an integral flange that runs under the roofing and serves the same function as a drip-edge.

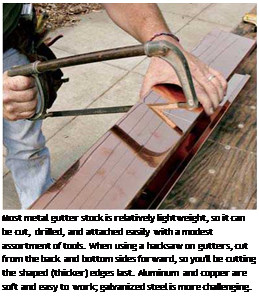

Metal gutters can be fabricated on site by a gutter specialist with a mobile machine. Or you can assemble them from 10-ft. or 20-ft. prefab lengths, using pop rivets and exterior caulking. Plastic gutter sections need cementing. Gutter runs that are longer than 40 ft. need an expansion joint to keep them from buckling. Here are the materials most commonly used.

Aluminum. By far the most popular, aluminum resists corrosion, is easily worked, is reasonably priced, and is durable—though it will dent. It comes prepainted in a range of colors. Standard thickness is 0.028 in., but spending a little more for 0.032 in. is prudent, especially if heavy snows and ice dams are common in your area.

Galvanized steel. Stronger and harder to dent than aluminum, galvanized steel rusts if you don’t keep it painted. There are prepainted varieties, generally in the same colors as painted metal roofs. The minimum thickness is 26 gauge.

|

For gutters, a pop riveter is indispensable for joining because, unlike screws, pop rivets don’t intrude into the gutter or downspouts and so won’t snag leaves and cause clogs. Predrill pop-rivet holes. |

Copper. Handsome when new, copper acquires a beautiful green patina as it weathers. It’s malleable, durable, and about five times as expensive as aluminum. This gutter is usually formed from 16-oz. sheet copper. Copper resists salt air but may be corroded by cedar-shingle runoff.

Plastic. Plastic comes in 8-ft. and 10-ft. lengths, with matched fittings. You can join sections either with liquid cement or with neoprene gaskets. It’s virtually maintenance free and durable, if the plastic contains a UV inhibitor. Its expansion joints can accommodate a wide range of movement.

Leave a reply