POST-FORMING A COUNTERTOP

|

|

|

|

|

|

|

and, to a degree, stain-proofs them, too. Miracle Sealant’s 511 Porous Plus, a penetrating sealer, is effective at stain-proofing cementitious materials from grout to concrete. One of the best books on casting your own countertop is Fu-Tung Cheng’s Concrete Countertops (The Taunton Press).

Wood is a sentimental favorite because it’s warm and beautiful, but it must be correctly finished and carefully sealed to prevent damage around sinks or along seams where water could collect. There are so many types of wood that it’s tough to generalize about traits, but most types scorch, scratch, and stain easily, and water will swell and rot wood unless you keep it sealed. Thus a growing number of fabricators such as Spekva of Denmark, are producing oil – finished, butcher-block and laminated-wood countertops that will remain durable if you peri

odically apply a food-safe oil recommended by the manufacturer. Such countertops are pricey but, in Spekva’s case, the wood is harvested from sustainable, managed forests.

POST-FORMED PLASTIC LAMINATE TOPS

Roughly half of residential laminate countertops are post-formed—in which a shop or factory adheres and wraps a single, continuous sheet of laminate to a particleboard substrate, creating a seamless joint between the counter and back – splash. This leak-free joint is the principal reason why most contractors order post-formed laminate tops rather than adhering the laminate to the substrate themselves. However, if you want a different transition from countertop to wall, perhaps a tile backsplash, or simply want to save money, laminating a flat countertop is not that difficult.

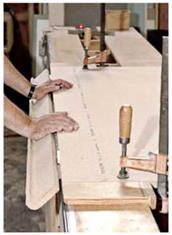

Although the photos in "Adhering Laminate Yourself,” on p. 314, were shot entirely in a custom counter shop, they depict the most critical steps for doing the job yourself. The photos in "Post-Forming a Countertop,” on p. 315, show tasks that require specialized equipment and can be done only in a shop. A custom counter shop will also trim the counter to length, trim excess laminate, and cut miter joints if the counter is L – or U-shaped.

Although the photos in "Adhering Laminate Yourself,” on p. 314, were shot entirely in a custom counter shop, they depict the most critical steps for doing the job yourself. The photos in "Post-Forming a Countertop,” on p. 315, show tasks that require specialized equipment and can be done only in a shop. A custom counter shop will also trim the counter to length, trim excess laminate, and cut miter joints if the counter is L – or U-shaped.

If you opt for a post-formed top, the installation becomes a good deal simpler. The counter installer’s principal tasks will then be scribing the top of the backsplash so it fits flush to the wall, drawing mitered sections together with draw – bolts, and securing the counter substrate to the top of the base cabinet. However, as discussed in the next section, the first step in fitting countertops is taking careful measurements.

Leave a reply