ORDERING COUNTERTOPS

Once you’ve identified several reputable countertop shops in your area, get bids. For your protection, develop detailed floor plans and, as you proceed, put everything in writing. That way, you’ll be sure that quotes from different shops reflect similar details, deadlines, and so on. The following guidelines are adapted, with permission, from Sullivan Counter Tops, Inc. (visit www. sullivancountertops. com).

Visit suppliers in your area. Look at countertops in several different showrooms, and discuss your options with the salespeople. Share any information—samples of wall paint or cabinet finishes, magazine ads showing counter surfaces, photos of sinks or sink fixtures—that will clarify the style and look you’re after. A salesperson’s willingness to spend time and answer questions says a lot about a supplier.

Get bids. Provide a floor plan, drawing, or sketch to the countertop suppliers, and ask each to generate a written bid. The bid should also specify a completion date, terms of payment, and the scope

of the installation. In most cases, quoted prices will not include plumbing, electrical work, or adjustments to the cabinets such as sink cutouts and leveling plywood substrates. Tearing out old countertops is usually extra, too. Based on bids and supplier reputations, choose a supplier.

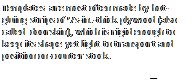

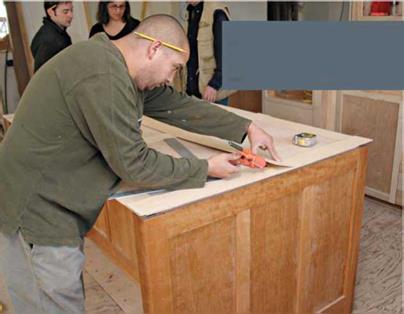

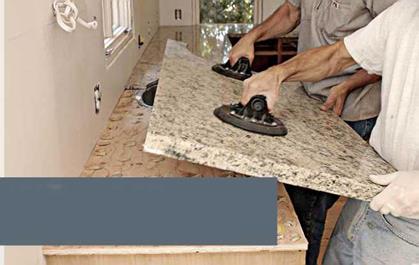

Schedule the job. Most installations require two visits from the supplier: the "measure date” and the "install date.” It’s difficult to pinpoint a measure date until the cabinets are installed, but in general, 2 weeks’ to 4 weeks’ notice should be enough. Typically, solid-surface (such as Corian) and plastic-laminate countertops require about 1 week between the measure date and the install date. Quartz-composite countertops (such as Zodiaq) require about 2 weeks. Most countertop suppliers will allow you to change the installation time without penalty, provided you give them enough notice.

Be prepared for meetings. The measure date is your last chance to give input on details such as underlayment issues, color, edge treatment, and splash detail. Whatever you finally decide on, get it in writing. During this meeting, the supplier will review job site conditions, so the general contractor should be there, too.

Important prerequisites

► Cabinets must be set before the job can be measured. In other words, the cabinets must be screwed together and screwed to the walls, not just pushed into place. The cabinets cannot be moved even И in. after the countertop supplier has measured because countertops are fabricated to close tolerances.

► Cabinets must be set level. As general rule, cabinets must be set on a level plane within % in. over a 10-ft. length. Such stringent requirements are a concern not only to installers but also, in some cases, to manufacturers as a condition of warranty.

► All appliances and sinks should be on the job site at the time of the measure. The fitting of sinks and appliances is often critically close. Design or construction issues that could cause problems or delay the installation should be resolved on the measure date. If the sinks and appliances are on site, the supplier can inspect them. If there’s a defect, damage, or, say, a sink rim that won’t fit the countertop, you’ll need time to replace the item before installation.

Because a kitchen is one the most-used rooms in the house, do a little research before choosing its most-used fixture.

|

|

||

|

|||

|

|||

|

|||

|

|||

|

|||

because water spots don’t show as conspicuously. A sink’s gauge (thickness) is the real differentiator. Thicker gauges (16 gauge to 18 gauge) are harder to flex and dent and are quieter to use; whereas thinner gauges (20 gauge to 22 gauge) are less expensive, less durable, and more inclined to stain. Cost: This can range widely, from $40 for a 22-gauge single-bowl

because water spots don’t show as conspicuously. A sink’s gauge (thickness) is the real differentiator. Thicker gauges (16 gauge to 18 gauge) are harder to flex and dent and are quieter to use; whereas thinner gauges (20 gauge to 22 gauge) are less expensive, less durable, and more inclined to stain. Cost: This can range widely, from $40 for a 22-gauge single-bowl

Leave a reply