Materials

This chapter of the

materials needed to frame and sheath a house. Materials include standard lumber; engineered lumber; sheet materials, such as plywood and particleboard; and fasteners, including nails, screws, and construction adhesives.

There’s never been a wider choice of building materials or more readily available information on using them, whether you need to size ceiling joists or find an environmentally safe adhesive that can bond frozen lumber. Just type your requirements into a Web site calculator or ask at your lumber supplier for a recommendation. Many related techniques are covered in Chapter 8.

Wood is a superb building material. It is strong, economical, and easily worked. Whether as a tree or as lumber, wood can withstand great loads, yet it’s resilient enough to regain its shape when loads are removed. Standard lumber is lumber sawn from logs in the traditional manner; whereas engineered lumber is often an amalgam of peeled, shredded, or reassembled wood pieces and strong adhesives.

After lumber has been milled, each piece is visually graded according to established performance standards and then stamped. This grade stamp is important because building inspectors won’t approve structures built with unstamped lumber. Otherwise they’d have no way of knowing what loads the wood can support. In brief, grading is based on the presence of warping, knots, holes, decay, or other imperfections that could weaken the lumber and reduce its load-bearing capacity. Generally, dimension lumber grades are based on

![]()

![]()

strength, appearance, or both. The more imperfections, the lower the grade.

strength, appearance, or both. The more imperfections, the lower the grade.

Grade stamps indicate lumber grade, tree species, moisture content when the lumber was surfaced, sawmill, and regional agency certifying the grading standards. Lumber that is stress rated by machine will have additional information.

Structural framing lumber grades run from Select Structural (the best looking and strongest) through No. 1, No. 2, and No. 3. An architect might specify Select Structural 4x8s, for example, when beams will be exposed in a living room. In most grading systems, No. 1 and No. 2 are

Here’s some standard lumberyard lingo:

► BOARDS are less than 2 in. thick and are used as trim, sheathing, subflooring, battens, doorstops, and such.

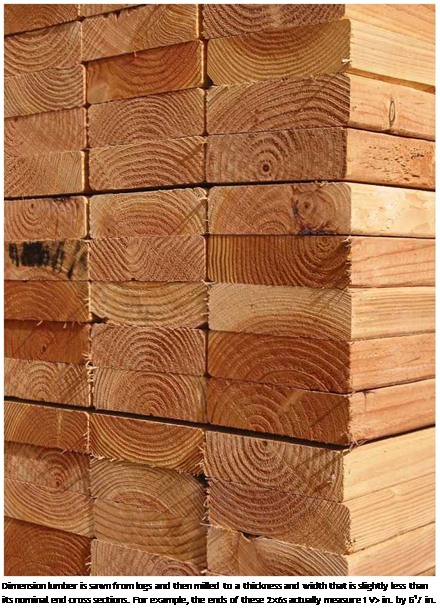

► LUMBER (dimension lumber) is 2 in. to 4 in. thick and is used for house framing: studs, posts, joists, beams, headers, rafters, stair carriages, and so on.

► FACTORY OR SHOP LUMBER is wood milled into window casings, trim, and other elements.

► TIMBER is at least 5 in. thick in its smallest dimension.

► STOCK applies to any building material in its unworked form, as it comes from the lumberyard or mill.

► A STICK is jargon for a piece of lumber, such as a 2×4: "If that stick is too warped, go get another."

equally strong, though No. 1 has fewer cosmetic flaws. Thus if appearance is not a factor, you can order "No. 2 and better” without sacrificing strength. No. 3 is the weakest and least expensive grade in the structural category; you won’t save much by using it, because you’ll have to order larger dimensions to carry the same loads as No. 1 and No. 2 grades.

Light framing lumber, which is used for plates, sills, and blocking, has lower strength requirements than structural framing members. Light framing members are 4 in. (thick or wide) or less. Grades are Construction (the best), Standard, and Utility. Contractors often order "Standard and better.”

Stud lumber is graded Stud or Economy Stud. In general, avoid Economy grade lumber of any kind. Although okay for temporary use, its inferior quality makes it unreliable in any sustained load-bearing situation.

Species are denoted by abbreviations such as PP (ponderosa pine), DF (Douglas fir), and HEM (hemlock). Often, manufacturers will group species with similar properties. S-P-F (spruce, pine, fir) is by far the most common Canadian grouping, and HEM-FIR (hemlock-fir) is common throughout the United States. Because lumber is heavy and expensive to ship, lumberyard sources tend to be from nearby mills. Since your lumberyard is likely to carry only a mixed stock of sizes and grades, your choice may be limited to what’s on hand.

Leave a reply