IS IT THICK ENOUGH TO SAND?

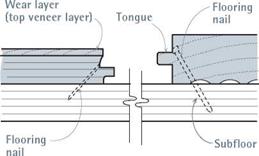

To avoid splintering wood floors when sanding them, keep at least ‘h in. of solid wood above the tongue of T&G flooring. The easiest way to assess the floor’s thickness is to remove a forced-hot-air floor register and look at the exposed cross section of flooring. If that’s not possible, pull up a threshold or a piece of trim and bore a small hole to expose a cross section. Or drill in a closet, where no one will see the hole. If you’ve got engineered flooring, its wear layer (top veneer layer) won’t be very thick to start with—Vn in. is typical— so start sanding with a less aggressive sandpaper, as suggested in "Floor-Sanding Materials,” on p. 490. In most cases, you can sand an engineered floor at least one or two times. But even if you have solid-wood flooring, avoid sanding into board tongues: T&G flooring is nailed through its tongues, and if you hit nails, the sandpaper will shred quickly.

|

ENGINEERED SOLID-WOOD FLOORING FLOORING |

|

Most sanding equipment can be rented. Be sure to have a knowledgeable person at the rental company explain how to operate the machines safely, how to change sandpaper and adjust wheels and drive belts, and what size circuit breaker or fuse each tool requires. Finally, inspect each piece of equipment. Sander drums and edger disks should be smooth and free of nicks or metal spurs that could scar floors. Check |

|

You can sand only the top veneer layer of engineered flooring. Solid-wood, tongue-and-groove (TaG) flooring is a lot thicker, but you can sand only to the top of its tongue. If you sand lower, you’ll hit flooring nails. TaG nail heads should be just flush, as shown. |

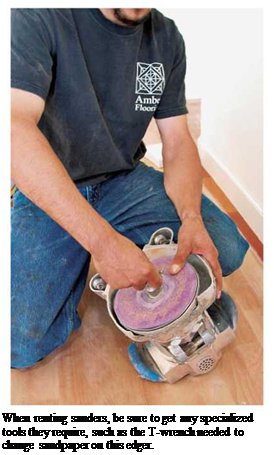

An edger (disk sander) goes where drum or belt sanders can’t—along the perimeter of floors and into tight nooks. (Large floor sanders should not be used within 6 in. of walls.) Edgers may be smaller than floor sanders, but they can still gouge flooring quickly. So first practice on plywood. The edger’s paper is held in place against a rubber disk by a washered nut. To prevent gouging the floor with the edger, many professionals leave three or four used disks beneath the new one, which cushions the cutting edge of the sandpaper somewhat.

An edger (disk sander) goes where drum or belt sanders can’t—along the perimeter of floors and into tight nooks. (Large floor sanders should not be used within 6 in. of walls.) Edgers may be smaller than floor sanders, but they can still gouge flooring quickly. So first practice on plywood. The edger’s paper is held in place against a rubber disk by a washered nut. To prevent gouging the floor with the edger, many professionals leave three or four used disks beneath the new one, which cushions the cutting edge of the sandpaper somewhat.

A buffer is a versatile tool. With abrasive buffer screens, it can lightly sand floor finishes you want to restore or fine-sand a floor that you’ve stripped down to bare wood. Its slow, oscillating movement is perfect to scuff-sand between finish coats. Or, when the final coat is down, you can

Leave a reply