INSTALLING THE WINDOW UNIT

Before installing window units, remove the packaging, shipping blocks, screens, storm windows, and so on. If the unit is uncased, screw temporary cleats to the outside edges of the frame so that when it is placed in the opening, its jamb edges will be flush to the sheathing. Window installation is a two-person job—one inside, one outside.

1. Dry – fit the window first.

Set the bottom of unit onto the RO sill and tilt the window up into place. There should be roughly h in. of space on both sides of the unit and h in. to 1 in. above. Using a spirit level, the person outside quickly checks for level and plumb. If there are no glaring problems, set the unit aside and caulk around the opening.

2. Caulking details will vary. For most precased or flanged units, apply a continuous 18-in. bead of siliconized acrylic caulk along the sides and top of the RO, back h in. from the edge, and press the casing or flange of the new unit into the caulking for a good seal. If the unit is uncased, caulk only along the bottom of the opening, at this stage.

3. Now install the window. As the outside person supports the unit, the inside person uses a small flat bar inserted between the RO and the frame to center the unit in the opening. That done, the person outside uses a spirit level to check the window’s sill and head for level, while the person inside uses the flat bar and adds shims as needed. Once the unit is level and plumb, the outside person uses a tape measure to check the frame’s “diagonals” (opposite corners of the frame). If diagonal measurements are equal, the frame is square.

4. When the unit is level and plumb, nail the upper corners of precased units and units with nailing fins. Tack uncased units with a nail or screw centered in each side jamb, down about 4 in. from the top of the frame. Open and close the window to see if it binds. Where the frame binds, use screws to draw it out or shims to push it into the opening. If you are installing a double – hung window, make sure the meeting rails meet evenly.

|

After dry-fitting the window, flash the sill of the RO and run a bead of siliconized acrylic latex caulk near the corner so the window seats in it. Once the window is in place, apply an additional bead of caulk to the underside of the windowsill to cut air infiltration. |

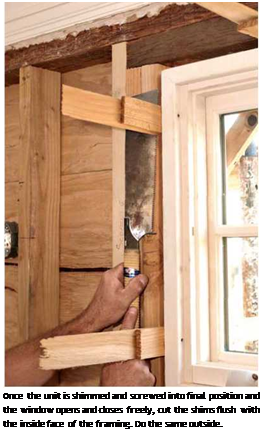

Use a Japanese saw or a utility knife to cut the shims flush to the interior finish surfaces and exterior sheathing. Set the nails or sink the screws holding the frame to the opening, and then fill the holes. Use a mild-expanding polyurethane spray-foam sealant to stop air infiltration around the unit. This type of foam is less likely to bow window frames than a foam that expands aggressively (see Chapter 14).

Now weather-seal the outside of the opening.

If you installed a precased unit, it’s already set in caulking, so you’re ready to install the cap flashing. If the unit has continuous nailing flanges, seal the sides and sill with strips of self-adhering membrane. But install cap flashing before applying a self-adhering membrane strip across the top of the unit.

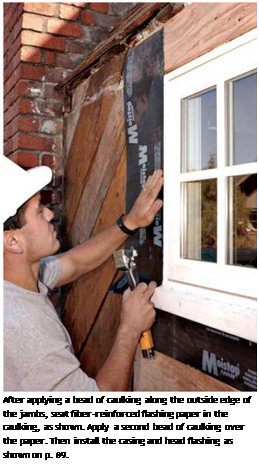

If the unit is uncased, like the unit shown in the photos, caulk the side jamb edges with siliconized acrylic caulk (run the beads back h in. from jamb edges), press fiberglass-reinforced strip flashing into the caulk, and nail the side casing to the jambs, using 8d galvanized finish nails. Then apply a bead of caulking to the edge of the head jamb and nail up the head casing to the side casings. To keep the joints from pulling apart, send one nail diagonally through each joint, too. Then apply the cap flashing (usually metal or vinyl), nailing through its top leg. Flashing strips, selfadhering membrane strips, or housewrap overlaps that top leg. Finally, apply a bead of surface caulk to the frame/sheathing joints all around.

Leave a reply