INSTALLING PADDING

Padding, which is usually 6 ft. wide, should run perpendicular to the carpet to prevent padding and carpet seams from lining up. If the padding has a slippery side, face it up so carpet can slide over it as you position it. Once you’ve rough-cut the padding, carefully position the pieces so they butt to each other. Do not overlap padding sections, which could create a raised welt under the carpet; likewise, padding should not overlap tackless strips. Trim the padding so it butts to the edge of the strips. Then use duct tape, or something as strong, to tape the padding seams together so they can’t drift.

If there’s a plywood subfloor, staple the padding every 6 in. around the perimeter of the

|

|

You may wonder why strips with dozens of tack points sticking up are called tackless. In the old days, carpet installers had to hem (fold over) and tack down carpet edges every inch or so, which took thousands of tacks. When someone finally realized that it would be much quicker to hook carpeting onto strips containing slanted, inverted tacks, a generation of installers gave thanks. By and large, the strips did away with edge tacking, hence the name tackless strips.

|

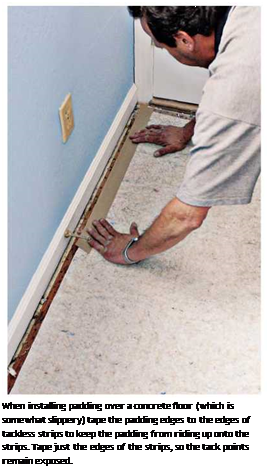

floor, and every 12 in. in the field, using 18-in. staples. If the substrate is concrete, sprinkle a latex-based carpet adhesive such as Parabond® M-4259 Solv-Free around the perimeter of the room and spread it out with a notched trowel; it’s not necessary to adhere the entire padding. Finally, because concrete is slippery, tape the padding edges so they can’t ride up onto tackless strips.

Leave a reply