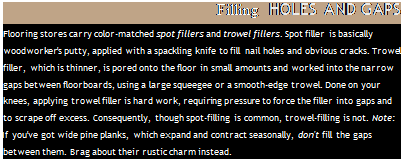

Finishes, Cleaning Solvents, and Applicators

|

FINISH |

CLEANS WITH |

APPLICATOR |

COMMENTS |

|

Water-based polyurethane |

Soap and water |

Synthetic brush; pad; round applicator |

Probably best all-around finish for nonpro; tough, water-resistant finish; easy cleanup, low smell; work fast, overlapping edged areas before they dry |

|

Oil-based polyurethane |

Mineral spirits |

Natural-bristle brush; round solvent-resistant applicator |

Tough, durable finish; favored by pros because dries slower than water-based; slightly stronger smell while drying |

|

Penetrating sealers (tung and modified linseed oils ) |

Mineral spirits |

Lamb’s wool applicator, natural-bristle brush |

Slow to dry; strong odor; scratches easily but can be touched up with new finish over old; usually waxed |

|

Stain-sealers |

Mineral spirits |

Varies: natural-bristle brush to clean rags |

Same profile as penetrating sealer; finish must be waxed to protect wood |

|

Varnish |

Turpentine or paint thinner |

Natural-bristle brush; lamb’s wool pads |

Volatile; strong smelling; slow to dry; hard, amber finish gives historical appearance; often used to match older finish |

|

Shellac |

Denatured alcohol |

Natural-bristle brush; lamb’s wool applicator |

Poor water resistance; flammable; chips; rarely used for floors anymore |

|

Various (acrylic – impregnated; acrylic – urethane; UV cured) |

Proprietary solvents |

Computer-monitored sprayer |

Factory applied in highly controlled environment; durable; water resistant coatings on prefinished wood flooring |

and sanding the floor a second time. If you need to fill holes or gaps in the floor, do it before the second sanding.

After you’ve drum-sanded and edged the floor with 100-grit sandpaper and vacuumed it well, use a buffer with an abrasive screen to smooth out any remaining marks. Use a 100-grit or 120-grit buffer screen, which is held onto the buffer pad by friction. Because the buffer rotates slowly and the screen is flexible, you can buff

right next to the base of the wall. Start along a wall, moving the buffer from side to side (it rotates in a counterclockwise direction). As you did with the drum sander, overlap passes about one-half the width of the buffer pad. Buffer screens wear out quickly, so replace them when you’ve screened one-third to one-half the floor. Save at least one used screen, so you can fold it and use it to hand-screen the corners where the buffer couldn’t reach.

To achieve an even smoother finish, vacuum the floor and wet-sponge it with clear water the night before screening it (the moisture will raise the grain slightly). The next day, when the wood flooring is dry, screen it smooth. Wetting the wood and then screening it is called popping the grain. Popping is optional, but strongly recommended if you’ll be applying a water-based finish. After screening the floor and touching up corners by hand, vacuum the room thoroughly and use clean tack rags to remove dust from any horizontal surface. (A tack rag is a slightly sticky cheesecloth pad that adheres dust.) Finally, dry-mop the floor, wrapping the mop in a clean cloth lightly dampened with the same solvent you used to thin the floor finish.

NOTSHAKEN

NOTSHAKEN

finishes to mix them, as you do paint. Shaking will entrap air bubbles and leave blemishes—popped bubbles—when the finish dries. Instead, stir finishes thoroughly from the bottom of the can. Don’t thin finishes. If stirring doesn’t dissolve the finish "skin” or other solids, strain the finish through a paint strainer.

Leave a reply