. DRILLING AND SCREWING ACCESSORIES

Magnetic bit holders magnetize drill bits so screws don’t fall off the bit. Some types also have a collet that keeps the screw centered as you drive them in.

Extension bit holders enable you to drive screws where drill/drivers won’t fit.

Flexible bit holders drive screws at angles drill/drivers can’t reach.

Drill bit extensions enable you to drill deeper with the bits you’ve got.

A ratchet-handle bit driver can turn Phillips – or

hex-head screws in tight spaces. They’re also

great for turning the leveling devices on refrigerator legs.

A stubby screwdriver has a reversible bit: one side Phillips-head, the other slotted.

A 4-in-1 screwdriver is the screwdriver to own, if you have only one.

Allen wrenches tighten Allen screws on a lot of tools, including drill bit extensions.

Quick-release bar clamps are a second set of hands on the job site. Use them to hold work to a bench, temporarily join two boards, align stair balusters, or mock up rafter pairs. Their rubber jaws won’t mar surfaces on fine work.

Standard bar clamps slide jaws to approximate position and use a threaded handle to draw materials tight. They’re a little slower than quick – release clamps, but they apply more force.

Spring clamps are the quickest to operate for relatively thin materials that don’t require an especially tight a grip.

Hand screws apply even pressure to a relatively broad area. Excellent for gluing, they hold work well and won’t damage wood. Open and close such clamps with two hands rotating, almost like pedaling a bicycle.

C-clamps apply a very strong force and are especially suitable when the workpiece absolutely mustn’t move. Insert scrap wood between the jaws and workpiece to protect it from jaw damage.

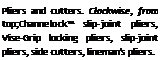

Slip-joint pliers are Old Reliables. Our grandfathers used the same design.

Channelock® slip-joint pliers have long, offset handles and jaws that open wide for the slip-nut under the kitchen sink.. .or wherever.

Vise-Grip® pliers have an adjustable tension mechanism that lets you lock the tool’s jaws on work, such as stripped screws. They can double as a temporary clamp, but don’t overtighten.

Side cutters are designed to cut wire or small nail shanks. But they’re also great nail pullers if you don’t squeeze too hard.

Lineman’s pliers are an electrician’s mainstay, great for twisting and cutting wire.

Aviation snips, also known as tinsips, cut sheet metal; use them for flashing and duct work.

Choose a hammer with a grip and weight that feel right for you. Bigger heads and longer handles can deliver greater impacts when nailing and so require fewer swings to drive nails. But they also require greater torquing force from you and so may cause tendonitis.

Twenty-six-ounce framing hammers are as big as anyone needs. Titanium framing hammers are in vogue these days because they transfer less shock to your arm, though more to your wallet.

Twenty-ounce framing hammers are light enough to double as trim hammers. But, truth is, pros prefer trim guns (pneumatic nailers) for finish work because they free-up one hand to steady the work and don’t ding the trim, like hammers do.

Sixteen-ounce finish hammers are fine for a small amount of trim.

Hand sledges are handy for knocking shoring or partitions a few inches over and for breaking loose stubborn foundation forms.

Hammer tackers are a quick way to staple building paper, insulation, and sheet plastic (see the photo on p. 68).

Leave a reply