CIRCUIT WIRING

Copper is the preferred conductor for residential circuit wiring. Aluminum cable is frequently used at service entrances, but it is not recommended in branch circuits.

Individual wires within a cable or conduit are color coded. White or light gray wires are neutral conductors. Black or red wires denote hot, or loadcarrying, conductors. Green or bare (uninsulated) wires are ground wires, which must be connected continuously throughout an electrical system.

Because most of the wiring in a residence is 120-volt service, most cables will have three wires: two insulated wires (one black and one white) plus a ground wire, usually uninsulated. Other colors are employed when a hookup calls for more than two wires; for example, 240-volt circuits and three – or four-way switches.

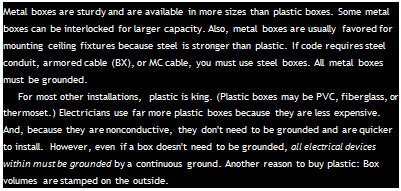

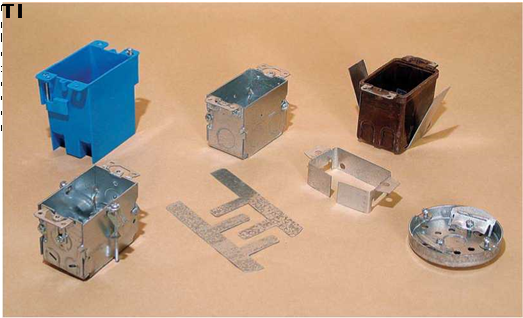

There is a huge selection of boxes, varying by size, shape, mounting device, and composition. But of all the variables to consider when choosing boxes, size (capacity) usually trumps the others. Install slightly oversize boxes, if possible: They’re faster to wire and, all in all, safer because jamming wires into small boxes stresses connections.

|

|

|

WIRING |

Aluminum wiring was widely used in house circuits in the 1960s and 1970s, but it was a poor choice. Over time, such wiring expands and contracts excessively, which leads to loose connections, arcing, overheating and—in many cases—house fires. If your house has aluminum circuit wiring, the most common symptoms will be receptacle or switch cover plates that are warm to the touch, flickering lights, and an odd smell around electrical outlets. Once arcing begins, wire insulation deteriorates quickly.

An electrician who checks the wiring may recommend adding COPALUM® connectors, CO/ALR-rated outlets and switches, or replacing the whole system.

Note: Aluminum service cable, thick stranded cable that connects to service panels, is still widely used because it attaches solidly to main lugs, without problems.

Capacity. The most common shape is a singlegang box. A single-gang box 3f2-in. deep has roughly 22Й cu. in. capacity: enough space for a single device (receptacle or switch), three 12/2 W/G cables, and two wire nuts. Double-gang boxes hold two devices; triple-gang boxes hold three devices. Remember: Everything that takes up space in a box must be accounted for— devices, cable wires, wire nuts, and cable clamps— so follow closely NEC recommendations for the maximum number of conductors per box.

You can get the capacity you need in a number of ways. Some pros install shallow foursquares (4 in. by 4 in. by 1И in. deep) throughout a system because such boxes are versatile and roomy. If a location requires a single device, pros just add a mud ring cover, as shown in the photo on p. 240. Because of their shallow depth, these boxes can also be installed back to back within a standard 2×4 wall. Thus you can keep even back-

to-back switch boxes at the same height, from room to room. Shallow pancake boxes (4 in. in diameter by J2 in. deep) are commonly used to flush mount light fixtures.

to-back switch boxes at the same height, from room to room. Shallow pancake boxes (4 in. in diameter by J2 in. deep) are commonly used to flush mount light fixtures.

Mounting devices. The type of mounting bracket, bar, or tab you use depends on whether you’re mounting to finish surfaces or structural members. When you’re attaching a box to an exposed stud or joist, you’re engaged in new construction or new work, even if the house is old. New-work

boxes are usually side-nailed or face-nailed through a bracket; nail-on boxes have integral nail holders. The mounting bracket for Veco® nonmetallic boxes is particularly ingenious (see the photos on p. 244). Once attached to framing, the box depth can be screw adjusted till it’s flush to the finish surface.

Adjustable bar hangers enable you to mount boxes between joists and studs; typically, hangers adjust from 14 in. to 22 in. Boxes mount to hangers via threaded posts or, more simply, by being screwed to the hangers. Bar hangers vary, too, with heavier strap types favored in walls, where boxes can get bumped more easily. Lighter hangers, as shown on p. 239, are typically used in ceilings, say, to support recessed lighting cans.

|

|

Cut-in boxes. The renovator’s mainstay is cut-in boxes because they mount directly to finish surfaces. These boxes are indispensable when you want to add a device but don’t want to destroy a large section of a ceiling or wall to attach to the framing. Several types are shown in the top photo at right. Most cut-in boxes have plaster ears that keep them from falling into the wall cavity; what vary are the tabs or mechanisms that hold them snug to the back side of the wall: screw – adjustable ears, metal-spring ears, swivel ears, or

|

bendable metal tabs (Grip – loks™). Important: All cut-in boxes, whether plastic or metal, must contain cable clamps inside that fasten cables securely. That is, it’s impossible to staple cable to studs and joists when they are covered by finish surfaces, so you need clamps to keep the cables from getting tugged or chafed by metal box’s edge.

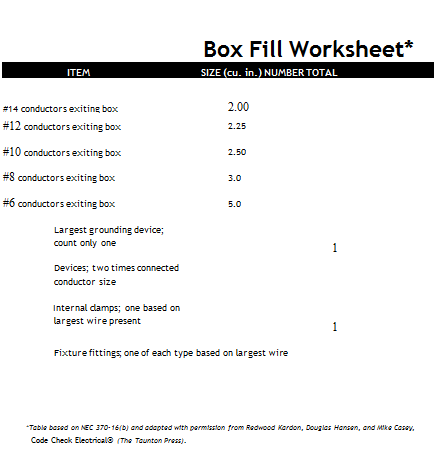

Clamps. Every wiring system— whether nonmetallic (Romex), MC, or conduit—has clamps (connectors) specific to that system. Clamps solidly connect the cable or conduit to the box so there can be no strain on electrical connections within the box and, as important, Romex clamps protect cable sheathing from burrs created when a metal box’s knockouts are removed.

GETTING BOX Edges FLUSH

GETTING BOX Edges FLUSH

Use an Add-a-Depth ring ("goof ring") to make box edges flush when an outlet box is more than ‘A in. below the surface—a common situation when remodelers dry – wall over an existing wall that’s in bad shape. To prevent the metal goof ring from short-circuiting screw terminals, first wrap electrical tape twice around the body of the receptacle or switch.

|

|

Leave a reply