Cabinet Basics

Cabinets today are basically boxes of plywood, particleboard, or medium-density fiberboard (MDF) panels that are glued and screwed together. Side panels, bottoms, and partitions are typically 3/ in. thick; back panels are usually in. thick. Cabinet faces are either frameless (the edges of the panels are the frame, although they may be veneered or edge-banded) or face frame (a four-sided wood frame covers the edges of each box).

Factory-made cabinets are frameless (also called European style). Having fewer elements and a simpler design, they are easier to manufacture. (The cabinets shown in the installation photos are frameless.) Doors and drawers typically lie flush on the case and overlay the panel edges. Usually, there’s % in. between the door and the drawer edges.

Face-frame cabinets are a bit more work, but offer more visual variety. You can expose more or less of the frame, vary the gaps between drawers and doors, use different hinge types, and so on. In general, designers who want a more ornamental, less severe, more traditional look often specify face-frame cabinets.

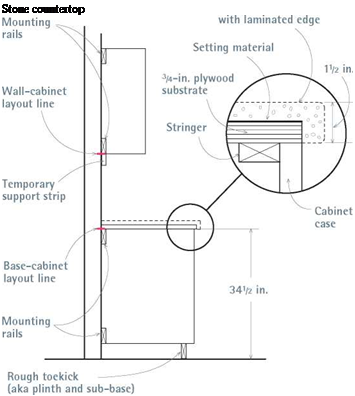

In addition to the elements above, cabinet cases have nailers (mounting rails) that you screw through to secure the cabinets to the studs. Base cabinets also have stringers— plywood webs across the top—to make boxes more rigid, keep partitions and sides in place, and provide something solid to screw the countertop to.

Kickspaces

The indentation at the bottom of a base cabinet that provides room for your toes, so you can belly up to the cabinet while prepping food or doing dishes, is called the kickspace. Without a kickspace, you’d need to lean forward to work at the counter—a sure recipe for backaches. Custom-made cabinets sit on a separate rough toekick (also called a plinth or sub-base), which is often assembled on site; whereas most (but not all) factory-made base cabinets arrive with toekicks built in. Toekicks are covered by a kickface, or finish toekick, a %-in. plywood strip with the same finish as the cabinets or a vinyl strip; the kickface is better installed after the finish floor.

Scribes

Cabinet assemblies also include small but important filler strips called a scribe pieces. These typically have a rabbeted back so they can be easily be ripped down to fill gaps between cabinets or between a cabinet and a wall. On a frameless cabinet, a separate scribe piece may be attached to a side panel, near its face; whereas on face-frame cabinets, the frame stile (vertical piece) has a rabbeted back edge (for scribing). In addition, many cabinet side panels extend slightly beyond the back panels, so those side panels can be scribed to fit snugly to the wall, as shown in the top left photo on p. 311. Custom cabinetmakers often create a separate scribe panel to dress up the end cabinet in a run and cover any gaps along the wall.

|

Better-grade cabinets have mounting rails on the outside of back panels so the rails are not visible inside the cabinet case. The edge detail shown in the enlargment is typical. The countertop substrate—here, 3/4 in. plywood-screws to stringers at the top of the cabinet case. Screw the cabinet bottom to the rough toekick. |

the cabinets—and review those measurements and conditions again after the cabinets arrive.

the cabinets—and review those measurements and conditions again after the cabinets arrive.

Leave a reply