ALERT

Dielectric unions have insulators inside that will not conduct electricity. If your electrical system is grounded to the water main and you install a dielectric union to join copper pipe to a galvanized steel service pipe, for example, install a bonding jumper to ensure continuous grounding.

llllll

Water-supply pipe supports. Clockwise from upper/eftvtwo Acousto-Plumb® clamps (which reduce pipe noise by cushioning vibrations), a copper pipe strap, a 3A-in. by 6-in. plastic-coated wire hook, two plastic suspension clamps, and a felt-lined J-clamp.

less. Support horizontal runs of CPVC supply pipe every 3 ft.; vertical runs should be suported every 10 ft., with clamps or plumber’s strap attached to blocking. Support PEX tubing every 32 in. on horizontal runs and every 10 ft. on vertical runs (with mid-story guides).

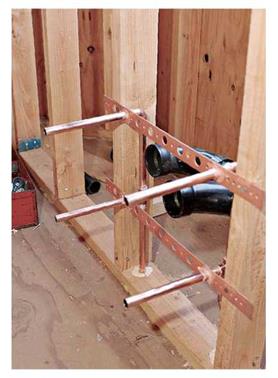

Keep hot and cold pipes at least 6 in. apart. They should never touch. To conserve energy, reduce utility bills, and get hot water sooner at fixtures, install closed-cell foam insulation sleeves on hot-water pipes, as shown in the photo on p. 224. As noted earlier, water-supply stub – outs should protrude at least 6 in. into living space. To hold stub-outs in place, solder them to perforated copper straps nailed or screwed to studs.

Code requires shutoff valves for every fixture riser. Supply pipes to outdoor spigots or unheated rooms should have shutoff valves and unions within the main basement so pipes can be drained. Install water-hammer arrestors on branch lines to appliances such as washers or dishwashers, whose solenoid valves stop water flow so abruptly that pipes vibrate and bang against the framing.

To test the supply system before installing dry- wall, solder caps onto fixture stub-outs and turn on the water. (If you’re installing CPVC supply,

cement caps onto stub-outs.) If there are no leaks, install steel nail-protection plates over any pipes that lie within 114 in. of a stud edge, or use steel stud shoes over notched studs. Then install finish surfaces.

![]()

![]()

Before you can install a new fixture, there’s often an old one to remove. If it’s necessary to shut off water to several fixtures during installation, capping disconnected pipes will allow you to turn the water back on.

Before you can install a new fixture, there’s often an old one to remove. If it’s necessary to shut off water to several fixtures during installation, capping disconnected pipes will allow you to turn the water back on.

Before disconnecting supply pipes, shut off the valves that control them. As mentioned, code requires a shutoff valve on each fixture riser, but older systems may have only a main valve that shuts off water to the whole house. After shutting off the controlling valve, open the faucets to drain the water.

old and you intend to reinstall it, save the water nuts because the threaded faucet stems may be nonstandard.

To disconnect a fixture’s drainpipe, use two pipe wrenches to loosen the slip-nut coupling of the P-trap. If older galvanized couplings have seized up, heat them with a MAPP gas torch and tap them lightly with a hammer to free the joint. Then try again with wrenches. Be sure to wear a respirator mask to avoid inhaling smoke from gaskets and such.

Once you’ve disconnected the drain and supply pipes, lift the lav/sink off its wall hanger, pedestal, or cabinet base and set it aside. An old cast-iron lav can be quite heavy, so lift it with the aid of helper. Place a plastic bag over the drain pipe stub and secure it with a rubber band to keep sewer gases at bay. Disconnect fittings carefully if you want to reuse them.

To remove a toilet, shut off the water by shutting the chrome fixture stop near the base of the unit. Flush the toilet and remove the remaining water with a cup or an inexpensive plastic hand pump. Disconnect the tank from the toilet bowl by loosening the bolts that hold the sections together. If the tank is wall hung, use a wide – jawed spud wrench to loosen the slip nut between the tank and the bowl. The toilet bowl is fastened to the floor by two bolts that rise from the floor flange; unscrew the nuts capping the bolts on both sides of the bowl. Rock the toilet bowl slightly to break the wax seal on the bottom.

Then lift up the bowl and immediately block the drainpipe by stuffing it with a plastic bag containing wadded-up newspapers.

Tub drain assemblies may be hidden in an end wall or they may exit into a hole cut into the subfloor under the drain. The drain and overflow assembly is usually held together with slip couplings, so use a pipe wrench to loosen them. If the drain is solid piece, cut through it. Supply pipes may be joined with unions or they may be soldered; it’s easiest just to cut through supply risers. With those pipes disconnected, you can move the tub.

If it’s a standard tub (rather than a freestanding tub), you may need to cut into the finish surfaces at least 1 in. above the tub to expose the tub lip, which is often nailed to studs. If you’re discarding the tub and don’t care about chipping its enamel, use a cat’s paw to pull the nails. If the tub is too heavy or tightly fit to slide out of its alcove, you may need to cut the studs of the end wall so you can slide the tub out.

![]()

INSTALLING LAVATORIES AND SINKS

Lavatory basins and sinks are supported by pedestals, cabinet counters, legs, wall-mounted brackets, or a combination of these. Cabinet-mounted lavs and sinks are particularly popular because they provide storage space.

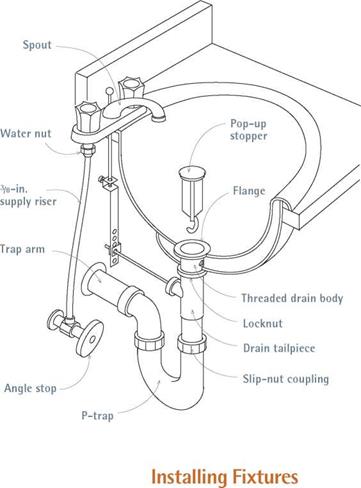

Preassemble the hardware. Before mounting a sink or lav, attach its hardware, including faucets, spout, and the drain tailpiece. Such connections are easier to make when the fixture is inverted. Insert the threaded faucet stems through predrilled holes in the sink or lav body, and tighten the washered nuts on the underside. Many manufacturers supply a rubber gasket; but when that’s lacking, spread a generous layer of plumber’s

putty between the metal and the porcelain. Don’t overtighten. Once the faucets are secure, you can connect the risers loosely to the threaded faucet stems, allowing you to reposition them if needed when attaching their lower ends to the angle stops.

Set the unit. Sink (or lav) installations vary, depending on whether the unit is surface mounted, under mounted, flush mounted, wall mounted, or set atop a pedestal. Once you’ve attached the hardware, apply a bead of silicone caulk to the sink lip, turn the unit over, and press it flat to the surface (or underside) of the counter. Some sinks need nothing more to secure them, although many have mounting clips similar to

Leave a reply