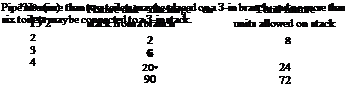

SIZING TALL STACKS

Sizing tall stacks will require you to use different sizing tables. A tall stack is one that has more than three branch intervals. Figure 4.19 and Figure 4.20 will show you the basics needed to size tall stacks for two different codes. There are differences in the number of fixture units allowed between the two codes. Since the tables are so much like others we have used, I won’t go into a lot of detail on them.

|

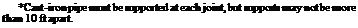

supports for drainage systems are needed. The distance between supports varies with the type of pipe being used and the local code that you are working with. There are also differences between vertical and horizontal piping when you are designing your support placement. We could talk about this, but it would be faster and easier to just give you some reference tables to use when you need them. Figure 4.21 is for horizontal pipe with one code and

FIGURE 4.20 ■ Stack-sizing tall stacks in Zone Three (stacks with more than three branch intervals). (Courtesy of McGraw-Hill)

|

|

ABS |

4 |

|

Cast iron |

At |

|

Galvanized (1 in and larger) |

12 |

|

Galvanized (% in and smaller) |

10 |

|

PVC |

4 |

|

Copper (2 in and larger) |

10 |

|

Copper (lVfc in and smaller) |

6 |

|

Support material |

FIGURE 4.21 ■ Horizontal pipe-support intervals in Zone One. (Courtesy of McGraw-Hill)

Figure 4.22 is for the same situation, but with a different code. Figure 4.23 deals with vertical pipes for one code, and Figure 4.24 shows vertical support requirements for a different code.

|

Type of drainage pipe

|

FIGURE 4.22 ■ Horizontal pipe-support intervals in Zone Two. (Courtesy of McGraw-Hill)

|

|

|

|

|

|

|

|

|||

|

|

||

|

FIGURE 4.24 ■ Vertical pipe-support intervals in Zone Two. [Courtesy of McGraw-Hill)

Leave a reply