ROLLING OFFSETS

Rolling offsets can be figured with a complex method or with a simplified method. since i assume that you are interested in the most accurate information that you can get in the shortest amount of time, i will give you the simplified version. The results will be the same as the more complicated method, but you will not pull out as much hair or lose as much time as you would with the other exercise, and you will arrive at the same solution.

|

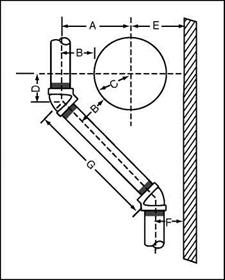

FIGURE 2.8 ■ Starting point of a 451 offset around a tank. |

|

FIGURE 2.9 ■ Simplified method of figuring a rolling offset. |

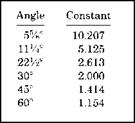

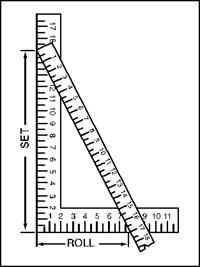

To figure rolling offsets simply, you will need a framing square, just a typical, steel, framing square. The corner of any flat surface is also needed, so that you can form a right angle. You will also need a simple ruler. The last tool needed is the table that I am providing in Fig. 2.9. This is going to be really easy, so don’t run away. Let me explain how you will use these simple elements to figure rolling offsets.

stand your framing square up on a flat surface. The long edge should be vertical and the short edge should be horizontal. The long, vertical section will be the Set, and the short, horizontal section will be the Roll. Your ruler will be used to tie the Set together with the Roll (Fig. 2.10 square and ruler). A constant will be needed to arrive at a solution, and you will find constants in the table I’ve provided in Fig. 2.9. Once again, the three main angles are addressed.

|

FIGURE 2.10 ■ Laying out a rolling offset with a steel square. |

When you refer to Fig. 2.9, you will find that the constant for a 45° bend is 1.414. The number for a 60° bend is 1.154, and the constant for a 22V2- bend is 2.613. If you were working with a 45° angle that had a Set of 15 inches and a Roll of eight inches, you would use your ruler to measure the distances between the two marks on the framing square. In this case, the measurement from the ruler would be 17 inches. You would multiply the 17-inch number by the 45° constant of 1.414 (found in Fig. 2.10) and arrive at a figure of 24V32 of an inch. This would be the length of the pipe, from center to center, needed to make your rolling offset. Could it get any easier?

Leave a reply