The remaining tables are different in content, but the procedures for using them are the same. Once you know the number of bedrooms and bathrooms for a dwelling, you can quickly and easily determine the minimum requirements for a water heater. You have just seen how simple the tables are. When you have a water heater to size, just refer to the tables in this chapter (Fig. 7.4, to 7.10) or the tables in your local codebook.

|

Number of bedrooms

|

2

|

3

|

4

|

5

|

|

Storage capacity (gallons)

|

30

|

40

|

40

|

50

|

|

Input in Btuh

|

36,000

|

36,000

|

38,000

|

47,000

|

|

Draw (gallons per hour)

|

60

|

70

|

72

|

90

|

|

Recovery (gallons per hour)

|

30

|

30

|

32

|

59

|

FIGURE 7.4 ■ Water heating sizing table for gas heaters (minimum recommendations). Assume 2 to 21/2 bathrooms.

|

Number of bedrooms

|

2

|

3

|

4

|

5

|

|

Storage capacity (gallons)

|

40

|

50

|

50

|

66

|

|

Input in Btuh

|

4.5 KW

|

5.5 KW

|

5.5 KW

|

5.5 KW

|

|

Draw (gallons per hour)

|

58

|

70

|

72

|

88

|

|

Recovery (gallons per hour)

|

18

|

22

|

22

|

22

|

FIGURE 7.5 ■ Water heating sizing table for electric heaters (minimum recommendations). Assume 2 to 21/2 bathrooms.

|

Number of bedrooms

|

2

|

3

|

4

|

5

|

|

Storage capacity (gallons)

|

30

|

30

|

30

|

30

|

|

Input in Btuh

|

70,000

|

70,000

|

70,000

|

70,000

|

|

Draw (gallons per hour)

|

89

|

89

|

89

|

89

|

|

Recovery (gallons per hour)

|

59

|

59

|

59

|

59

|

FIGURE 7.6 ■ Water heating sizing table for oil-fired heaters (minimum recommendations). Assume 2 to 21/2 bathrooms.

|

Number of bedrooms

|

3

|

4

|

5

|

6

|

|

Storage capacity (gallons)

|

40

|

50

|

50

|

50

|

|

Input in Btuh

|

38,000

|

38,000

|

47,000

|

50,000

|

|

Draw (gallons per hour)

|

72

|

82

|

90

|

92

|

|

Recovery (gallons per hour)

|

32

|

32

|

40

|

42

|

FIGURE 7.7 ■ Water heating sizing table for gas heaters (minimum recommendations). Assume 3 to 31/2 bathrooms.

|

Number of bedrooms

|

3

|

4

|

5

|

6

|

|

Storage capacity (gallons)

|

50

|

66

|

66

|

80

|

|

Input in Btuh

|

5.5 KW

|

5.5 KW

|

5.5 KW

|

5.5 KW

|

|

Draw (gallons per hour)

|

72

|

88

|

88

|

102

|

|

Recovery (gallons per hour)

|

22

|

22

|

22

|

22

|

FIGURE 7.8 ■ Water heating sizing table for electric heaters (minimum recommendations). Assume 3 to 3V2 bathrooms.

|

Number of bedrooms

|

3

|

4

|

5

|

6

|

|

Storage capacity (gallons)

|

59

|

59

|

59

|

59

|

|

Input in Btuh

|

70,000

|

70,000

|

70,000

|

70,000

|

|

Draw (gallons per hour)

|

89

|

89

|

89

|

99

|

|

Recovery (gallons per hour)

|

59

|

59

|

59

|

59

|

FIGURE 7.9 ■ Water heating sizing table for oil-fired heaters (minimum recommendations). Assume 3 to 3V2 bathrooms.

|

|

Column 1

|

Column 2

|

|

Buildings of ordinary tightness

|

Buildings of unusually tight construction

|

|

Condition

|

Size of opening or duct

|

Condition

|

Size of opening or duct

|

|

Appliance in unconfined2

space

|

May rely on infiltration alone.

|

Appliance in unconfined2 space:

Obtain combustion air from outdoors or from space freely communicating with outdoors.

|

Provide two openings, each having 1 sq. in. per 5,000 Btu/h input.

|

|

Appliance in confined4 space

1. All air from inside building

|

Provide two openings into enclosure each having one square inch per 1,000 Btu/h input freely communicating with other unconfined interior spaces. Minimum 100 sq. in. each opening.

|

Appliance in confined4 space:

Obtain combustion air from outdoors or from space freely communicating with outdoors.

|

1. Provide two vertical ducts or plenums: 1 sq. in. per 4,000 Btu/h input each duct or plenum.

2. Provide two horizontal ducts or plenums: 1 sq. in. per 2,000 Btu/h input each duct or plenum.

3. Provide two openings in an exterior wall of the enclosure: each opening 1 sq. in per 4,000 Btu/h input.

4. Provide one ceiling opening to ventilated attic and one vertical duct to attic: each opening 1 sq. in. per 4,000 Btu/h input.

|

|

2. Part of air from inside building

|

Provide two openings into enclosure3 from other freely communicating unconfined2 interior spaces, each having an area of 100 sq. in. plus one duct or plenum opening to outdoors having an area of 1 sq. in. per 5,000 Btu/h input rating.

|

|

|

3. All air from outdoors: Obtain from outdoors or from space freely communicating with outdoors.

|

Use of any of the methods listed for confined space in unusually tight construction as indicated in Column 2.

|

|

5. Provide one opening in enclosure ceiling to ventilated attic and one opening in enclosure floor to ventilated crawl space: each opening 1 sq. in. per 4,000 Btu/h input.

|

’For location of opening, see Section 1307(c).

2As defined in Section 122,

3When the total input rating of appliances in enclosure exceeds 100,000 Btu/h, the area of each opening into the enclosure shall be increased 1 sq. in. for each 1,000 Btu/h over 100,000,

4As defined in Section 104(h).

|

|

FIGURE 7.10 ■ Size of combustion air openings or ducts for gas-or liquid-burning water heaters. [Courtesy of Uniform Plumbing Code)

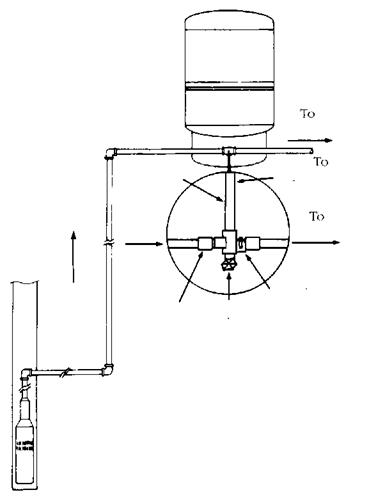

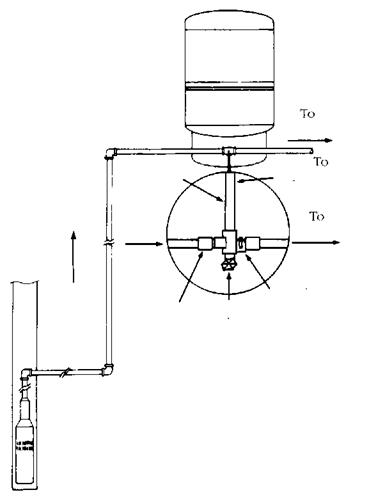

ome plumbers work their entire careers without ever having to know anything about water pumps. Other plumbers deal with pumps on a frequent basis. The difference is where the plumbers work. I’ve never worked in New York City, but I suppose there are not many water pumps to be installed or serviced. But where I live, in Maine, there are more homes served by private water wells than you can shake a stick at. When I lived in Virginia, there were plenty of water pumps, too. Some of the pumps are jet pumps and others are submersible pumps. The two are very different, even though they do the same job.

Jet pumps are at their best when used in conjunction with shallow wells, with depths of say 25 feet or less. Two-pipe jet pumps can be used with deep wells, but a submersible pump is usually a better option for deep wells. Sizing water pumps and pressure tanks is routine for some plumbers and foreign to others. This chapter is going to give you plenty of data to use when working with pump systems.

The illustrations I have to offer you in this chapter are detailed and selfexplanatory. I believe that you will be able to use this chapter as a quick-reference guide to most of your pump questions. Look over the following illustrations and you will find data on jet pumps, submersible pumps, and pressure tanks. The data will prove very helpful if you become involved with the installation, sizing, or repair of water pumps (Figs. 8.1 to 8.37).

135

|

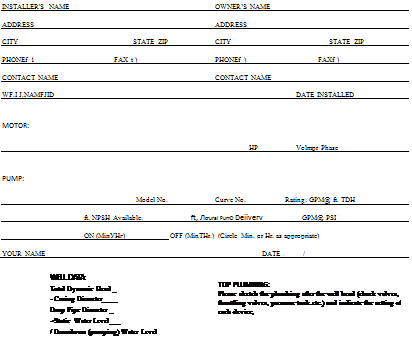

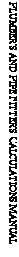

This check list is intended to bdp in making reliable submersible pump installations. Other data for specific pumps may be needed.

|

|

|

1. Motor Inspection

___ Л. Verify thai lire model. HP or KW. voltage, phase

and heitz on the motor nameplate match the installation requirements. Consider any special comision resistance required.

___ B, Check that I he motor lead assembly ts tight in Uie

motor and that the motor and lead are not damaged.

___ C. Test insulation resistance using a 500 or l(MX) volt

DC inegohmmeier, from each lead wire to the motor frame, Resistance should be at least 20 megohms, motor only, no cable.

D. Keep a record of motor model number, HP or KW, voltage, date code and serial number,

2. Pump Inspection

___ A. Check that the pump rating matches the motor, and

that it is not damaged.

___ B. Verily that the pump shaft turns freely.

3. Pump/Motor Assembly

___ A. If not yet assembled, check that pump and motor

mounting faces are free from dirt and uneven paint

thickness.

___ B, Assemble the pump and motor together so their

mourning faces are in contact, then tighten assembly holis or nuts evenly to manufacturer specifications.

И it is visible, chuck dial the pump shaft is raised slightly by assembly to the motor, conlilining impeller running clearance.

___ C. If accessible, check that the pump shaft rums freely.

___ D. Assemble the pump lead guard over the motor

leads. Do not eui nr pinch lead wire during assembly or handling of the pump during installation.

4. Power Supply and Controls

__ A. Verify that the power supply voltage, here?., and

KVA capacity malch motor requirements.

B, Use a matching control box with each single phase three wire motor.

___ C. Check that the electrical installation arid controls

meet all safety regulations and match the motor requirements, including fuse or circuit breaker size and motor overload protection. Connect all metal plumbing and electrical enclosures to (he power supply ground in prevent shock hazard, Comply with National and local codes.

5. Lightning and Surge Protection

___ A. Use properly rated surge (lightning) arresiors on all

submersible pump installations unless the installation is operated directly from an individual generator and/or is not exposed to surges. Motors 5HP and smaller which are marked “Equipped with Lightning Arrestors’contain internal arrestors.

|

|

|

B. Ciround all above ground arrestors with copper wire directly to the motor frame. or to metal drop pipe or casing which reaches below the well pumping level, Connecting to a ground rod does not provide good surge protection.

|

|

|

6. Electrical Cable

___ A. Use cable suitable for use in water, sized to carry’ the

motor current without overheating in water and in air, and complying with local regulations. To maintain adequate voltage at die motor, use lengths no longer than specified in die motor manufacturer s cable charts,

___ B. Include a ground wire to liie pump if required by

codes or. surge protection, connected lo the power supply ground Always ground any pump operated outside a drilled well.

7. Well Conditions

___ A, For adequate cooling, motors must have at least the

water flow shown on ils nameplate. If well conditions and construction do not assure this much water How will always come from below the motor, use a flow’ sleeve as shown in the Application, Installation & Maintenance Manual

___ B. If water temperature exceeds JO degrees C <86 T).

reduce live motor loading or increase the How rate to prevent overheating, as specified in the Application. Installation & Maintenance Manual.

B. Pump/Motor Installation

___ A. Splice motor leads lo supply cable using electrical

grade solder or compression connectors, and carefully insulate each splice with watertight tape or adhesive-lined shrink tubing, as shown in motor or pump installation data.

___ B. Support the cable to the delivery pipe every 10 feel

(3 meters) with straps or tape strong enough to prevent sagging. Use pads between cable and any metal straps.

___ C. A check valve in the delivery pipe is recommended,

even though a pump may be reliable without one. More than one check valve may be required, depending cm valve rating and pump setting. Install the lowest check valve below the lowest pumping level of the well, lo avoid hydraulic shocks which may damage pipes, valve or motor.

___ D. Assemble all pipe joints as lightly as practical, to

prevent unscrewing from motor torque. Recommended torque is at least 10 pound feet per HP (2 mcter-KG per KWi.

___ E. Set the pump fur enough below the lowest pumping

level to аччигс the pump inlet will always have at least the Net Positive Suction 1 lead |NPSI l) specified by the pump manufacturer, but at least 11) leet (3 meters) from the bottom of the well lo allow for sediment build up.

|

|

|

___ F. Cheek, insulation resistance from dry motor cable

ends to ground as the pump is installed, using а 5Ш or KM) volt DC megohm meter. Resistance may drop gradually as mere cable enters the water, but any sudden drop indicates possible cable, splice or motor lead damage. Resistance should meet motor manufacturer data,

9. After Installation

___ A. Check all electrical and waterline connections and

parts before starting the pump, Make sure water delivery will not wd any electrical parts, and recheck that overload protection in three phase controls meets requirements.

___ B. Strut the pump and check motor amps and pump

delivery. If normal, continue to run the pump until delivery is clear. If three phase pump delivery is low, it may be running backward because phase, sequence is reversed. Rotation may be reversed (with power off) by interchanging any two motor lead connections to the power supply.

___ C. Connect three phase motors for current balance

within 5% of average, using motor manufacturer instructions. Unbalance over 5c7c will cause higher motor temperatures and may cause overload trip, vibration, and reduced life.

___ D. Make sure that starling, running and stopping cause

no significant vibration or hydraulic shocks.

___ E. A Iter at least 15 minutes running, verify that pump

output, electrical input, pumping level, and other characteristics arc stable and as specified.

Date____________________ Filled In By

10. Installation Data

Well Identification_________________________________ _________________________________________

Check By ____________________________________ _

Date___ /____ (_____

Notes __________________________________________

|

|

|

|

|

|

|

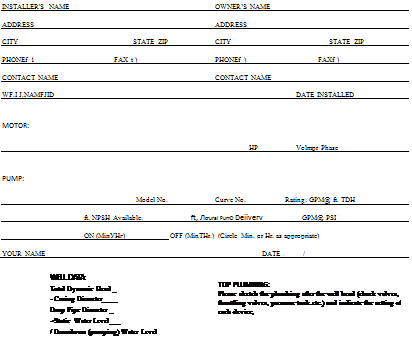

Pump Inlet Setting___

Flow Sleeve: No

|

|

|

|

|

Casing Depth______ Jt

□ Well Screen □ Perforated Casing From__ to_________ ft. &__ to________ ft-

|

|

|

– Well Depth_

Form No. 2207 2AM

|

|

|

Average water requirements for general

|

|

|

service around the home and farm

|

|

|

Each person per day, for all purposes

|

|

75 gal.

|

|

Each horse, dry cow, or beef animal

|

|

12 gal.

|

|

Each milking cow

|

|

35 gal.

|

|

Each hog per day

|

|

4 gal.

|

|

Each sheep per day

|

|

2 gal.

|

|

Each 100 chickens per day

|

|

4 gal.

|

|

Average amount of water required by

|

|

|

various home and yard fixtures

|

|

|

Drinking fountain, continuously flowing

|

50 to 100 gal. per day

|

|

Each shower bath

|

Up to 30 gal. @ 3-5 gpm

|

|

To fill bathtub

|

|

30 gal.

|

|

To flush toilet

|

|

6 gal.

|

|

To fill lavatory

|

|

2 gal.

|

|

To sprinkle V4" of water on each 1000

|

|

|

|

square feet of lawn

|

|

1б0 gal.

|

|

Dishwashing machine — per load

|

7 gal. @ 4 gpm

|

|

Automatic washer —per load

|

Up to 50 gal. @ 4-6 gpm

|

|

Regeneration of domestic water softener

|

|

50-100 gal.

|

|

Average flow rate requirements by

|

|

|

various fixtures

|

|

|

|

(gpm = gal. per minute; gph =

|

gal. per hour)

|

|

|

Shower

|

|

3-5 gpm

|

|

Bathtub

|

|

3-5 gpm

|

|

Toilet

|

|

3 gpm

|

|

Lavatory

|

|

3 gpm

|

|

Kitchen sink

|

|

2-3 gpm

|

|

У2” hose and nozzle

|

|

200 gph

|

|

1/4" hose and nozzle

|

|

300 gph

|

|

Lawn sprinkler

|

|

120 gph

|

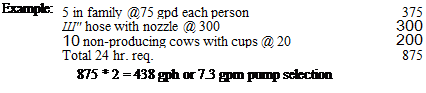

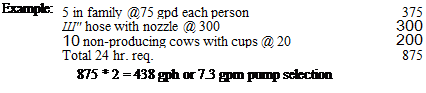

FIGURE 8.3 ■ Average water requirements for general service. (Courtesy of McGraw-Hill)

|

Each horse

|

Approx. Gallons Per Day

12

|

|

Each producing cow

|

15

|

|

Each nonproducing cow

|

12

|

|

Each producing cow with drinking cups

|

30-40

|

|

Each nonproducing cow with drinking cups

|

20

|

|

Each hog

|

4

|

|

Each sheep

|

2

|

|

Each 100 chickens

|

4-10

|

|

Yard fixtures:

|

|

Vi-inch hose with nozzle

|

200

|

|

M-inch hose with nozzle

|

300

|

|

Bath houses

|

10

|

|

Camp

|

|

Construction, semipermanent

|

50

|

|

Day (with no meals served)

|

15

|

|

Luxury

|

100-150

|

|

Resorts (day and night, with limited plumbing)

|

50

|

|

Tourists with central bath and toilet facilities

|

35

|

|

Cottages with seasonal occupancy

|

50

|

|

Courts, tourists with individual bath units

|

50

|

|

Clubs

|

|

Country (per resident member)

|

100

|

|

Country (per nonresident member present)

|

25

|

FIGURE 8.4 ■ Daily water requirements. (Courtesy of McGraw-Hill)

|

Dwellings

Luxury

Multiple family, apartments (per resident)

Rooming houses (per resident)

Single family Estates _

Factories (gallons/person/shift)

Institutions other than hospitals Hospitals (per bed)

Laundries, self-serviced (gallons per washing, i. e., per customer)

Motels

With bath and toilet (per bed space)

Parks

Overnight with flush toilets Trailers with individual bath units Picnic

With bath houses, showers, and flush toilets With only toilet facilities (gal./picnicker) Restaurants with toilet facilities (per patron)

Without toilet facilities (per patron)

With bars and cocktail lounge (additional quantity) Schools Boarding

Day with cafeteria, gymnasiums and showers Day with cafeteria but no gymnasiums or showers Service stations (per vehicle)

Stores (per toilet room)

Swimming pools Theaters

Drive-in (per car space)

Movie (per auditorium seat)

Workers

Construction (semipermanent)

Day (school or offices per shift)

|

|

|

75

60

50

75

100-150

15-35

75-125

250-400

50

100

25

50

20

10

10

3

2

50-70

25

20

10

400

10

5

5

50

15

|

|

|

Providing an adequate water supply provides for a healthy family and higher production from livestock. Assuming the total daily requirement is calculated to be 1200 gpd (gallons per day), a pump would be selected for a capacity of 10 gpm (gallons per minute) based on the following formula:

|

|

|

1200 gph t 2 equals 600 gph (gal. per hr.)

|

|

|

|

FIGURE 8.4 ■ (Continued) Daily water requirements. (Courtesy of McGraw-Hill)

|

|

|

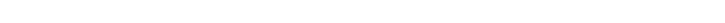

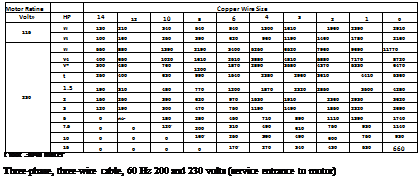

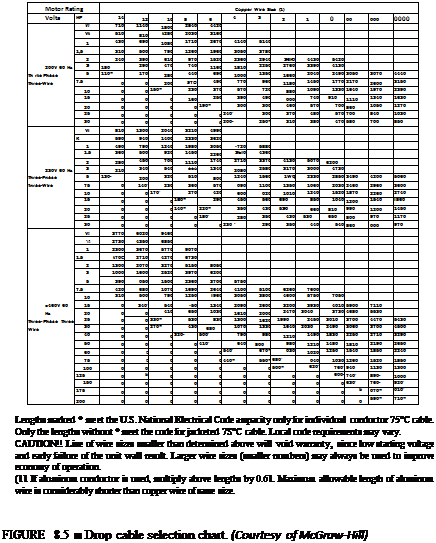

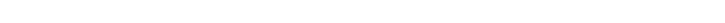

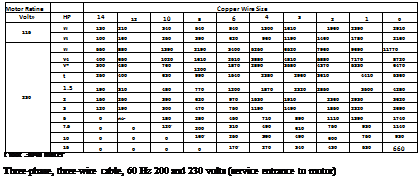

Engineering Data

Drop Cable Selection Chart

Single-phase, two or three-wire cable, 60 Hz (service entrance to motor)

|

|

|

|

|

Engineering data

Formulas and conversion factors

Centrifugal pumps

|

|

|

|

|

|

Volume

1 U. S, gallon – 231 cu. in,

1 U. S. gallon =■ 3-785 liters 1 Imperial gallon *1.2 U. S.

gallons

1 barrel (oil) я 42 U. S, gallons 1 cubic foot * 7.48 U. S, gallons

1 acre foot = 325,850 U. S.

gallons

1 cubic meter * 264,2 U. S.

gallons

Weight

1 U. S. gallon water weighs 8,35 lbs.

1 cubic foot water weighs

|

|

|

Head

1 lb. per sq. in. = 2.31 ft. of water 1 foot of water = 0-433 lbs. per sq. in. 1 inch of mercury = 1,133 ft. of water 1 atmosphere (sea level) – 14.7 lbs, per sq. in.

1 kilogram per sq. centimeter * 14,22 lbs. per sq. in.

Length

1 meter » 3.28 feet – 39.37 inches Power

1 horsepower = 745-7 watts 1 kilowatt * 1000 watts 1 kilowatt = 1.341 HP 100 boiler HP requires 7 gpm feed water approximately.

|

|

|

|

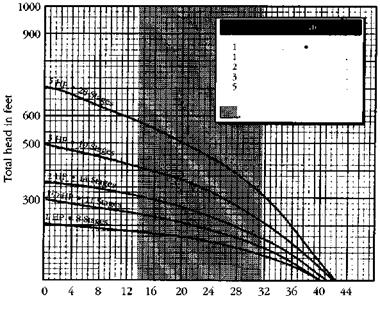

FIGURE 8.7 ■ Pressure tank in use with a submersible pump. (Courtesy of McGraw-Hill)

|

О 1 2 3 456789 10 11 12

U. S. gallons per minute

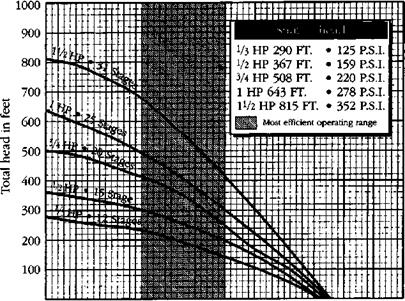

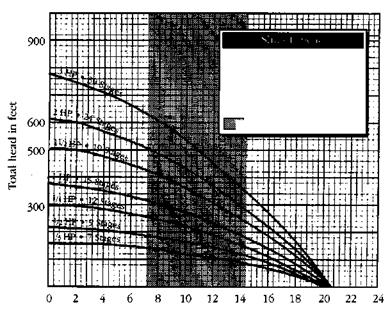

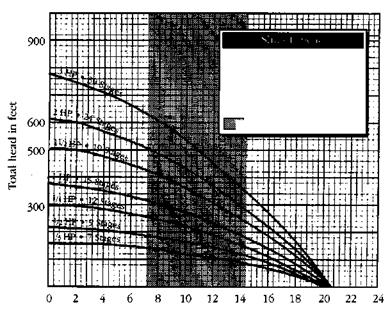

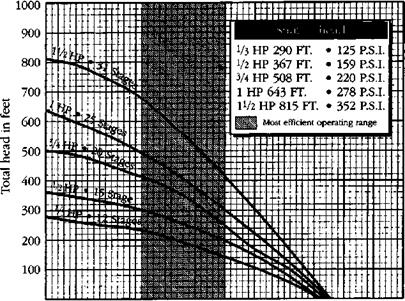

FIGURE 8.8 ■ Performance rating chart for pump with 5 gallon-per- minute output. (Courtesy of McGraw-Hill)

|

|

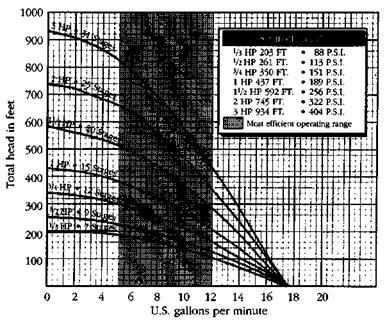

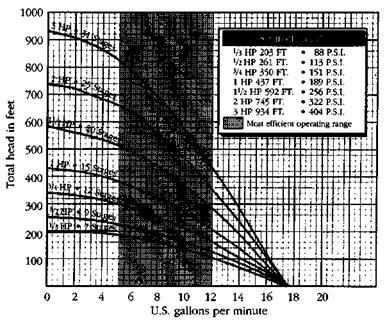

FIGURE 8.9 ■ Performance rating chart for pump with 10 gallon-per- minute output. (Courtesy of McGraw-Hill)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

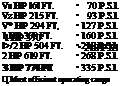

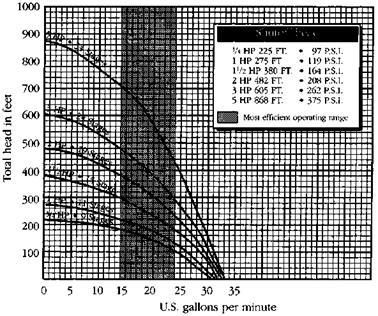

FIGURE 8.10 ■ Performance rating chart for pump with 13 gallon-per – minute output. (Courtesy of McGraw-Hill)

|

|

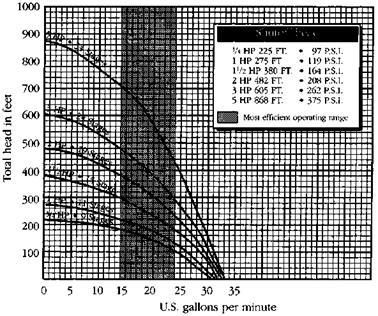

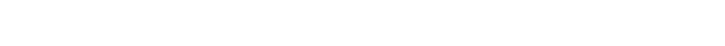

FIGURE 8.12 ■ Performance rating chart for pump with 25 gallon-per – minute output. (Courtesy of McGraw-Hill)

|

Output In gallons per hour

Discharge pressure 0 P. S.I.

|

|

|

|

|

|

Impeller

|

Pres, switch

|

Suction

|

Discharge

|

Shipping

|

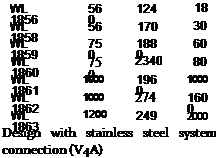

|

Model no.

|

HP

|

Volts

|

material

|

setting

|

pipe size

|

size

|

weight

|

|

8130

|

Уз

|

115

|

Plastic

|

20-40

|

1У4”

|

■1/4"

|

46 lbs.

|

|

8131

|

Уз

|

115

|

Brass

|

20-40

|

1У4"

|

|

48 lbs.

|

|

8150

|

y2

|

115/230

|

Plastic

|

20-40

|

1У4”

|

‘■’A"

|

48 lbs.

|

|

8151

|

y2

|

115/230

|

Brass

|

20-40

|

1У4"

|

|

50 lbs.

|

|

8170

|

3/4

|

115/230

|

Plastic

|

30-50

|

IV*’

|

%"

|

50 lbs.

|

|

8171

|

3/4

|

115/230

|

Brass

|

30-50

|

1У4"

|

%"

|

52 lbs.

|

|

8110

|

1

|

115/230

|

Plastic

|

30-50

|

1У4”

|

|

52 lbs.

|

|

8111

|

1

|

115/230

|

Brass

|

30-50

|

1У4"

|

|

53 lbs.

|

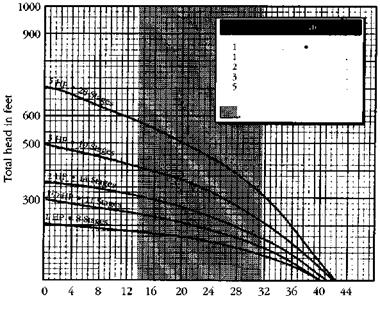

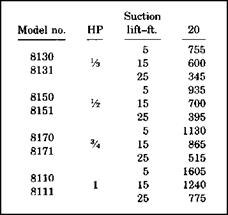

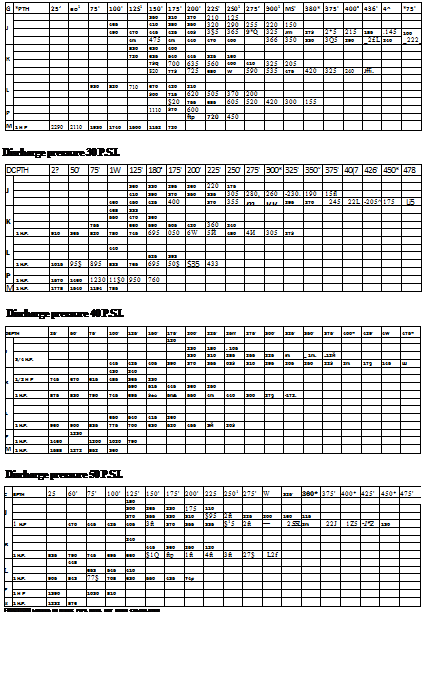

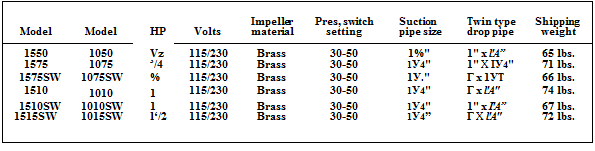

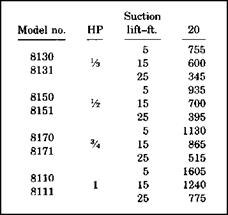

FIGURE 8.14 ■ Performance ratings for jet pumps. (Courtesy of McGraw-Hill)

FIGURE 8.15 ■ Performance ratings for multi-stage pumps. [Courtesy of McGraw-Hill)

|

FIGURE 8.16 ■ Shallow-well performance chart. (Courtesy of McGraw-Hill)

|

|

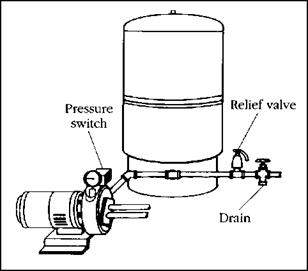

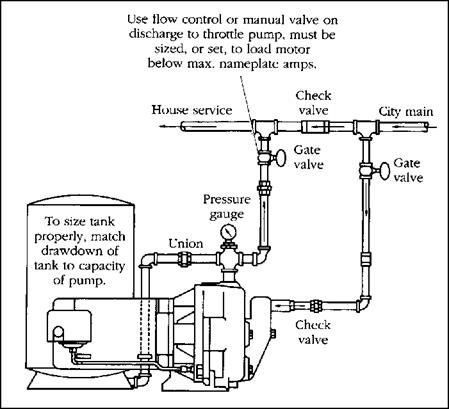

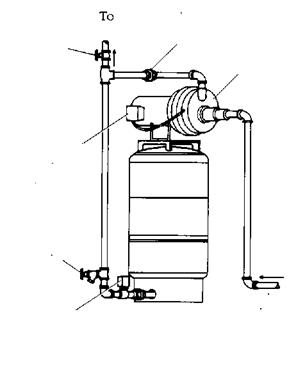

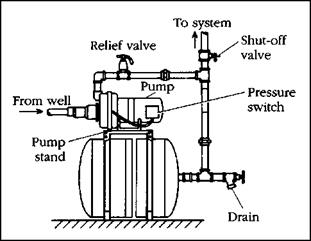

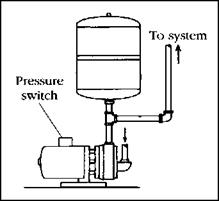

FIGURE 8.17 ■ A typical jet-pump set-up. (Courtesy of McGraw-Hill)

|

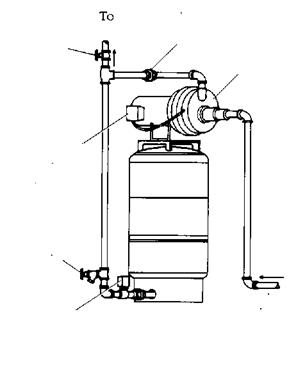

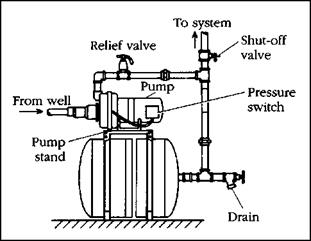

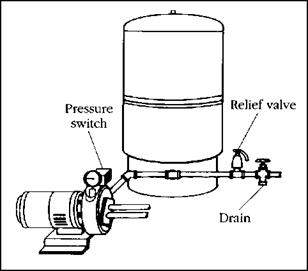

FIGURE 8.18 ■ A jet pump mounted on a pressure tank with a pump bracket. (Courtesy of McGraw-Hill)

|

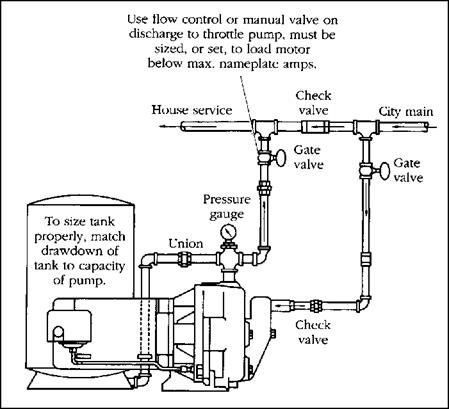

FIGURE 8.19 ■ A typical piping arrangement for a jet pump. (Courtesy of McGraw-Hill)

|

|

FIGURE 8.20 ■ Bracket-mounted jet pump on a horizontal pressure tank. (Courtesy of McGraw-Hill)

|

|

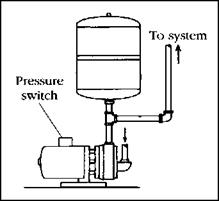

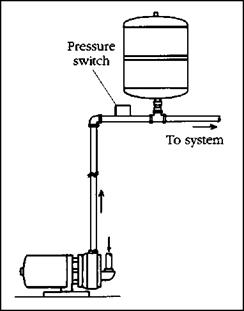

FIGURE 8.21 ■ Small, vertical pressure tank installed above pump. (Courtesy of McGraw-Hill)

|

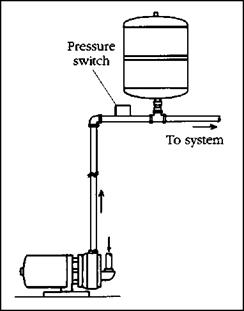

|

FIGURE 8.22 ■ Small, vertical pressure tank installed above pump. (Courtesy of McGraw-Hill)

|

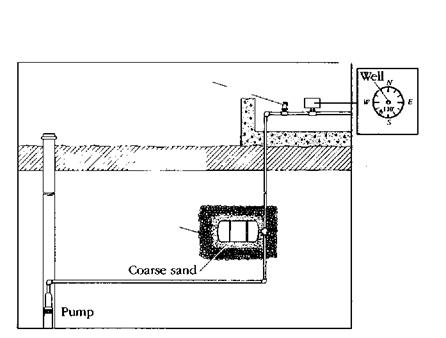

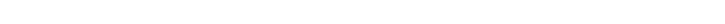

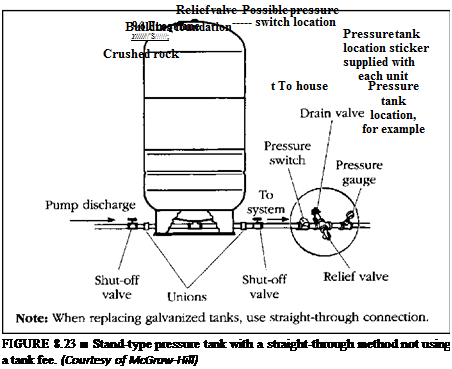

FIGURE 8.24 ■ An underground installation of a pressure tank. (Courtesy of McGraw-Hill)

FIGURE 8.24 ■ An underground installation of a pressure tank. (Courtesy of McGraw-Hill)

|

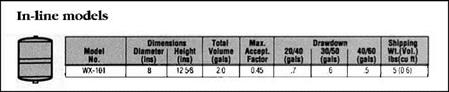

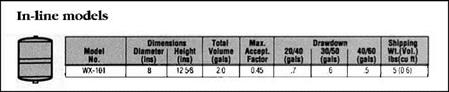

FIGURE 8.25 ■ In-line pressure tank. (Courtesy of McGraw-Hill)

|

|

|

|

|

|

|

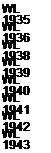

|

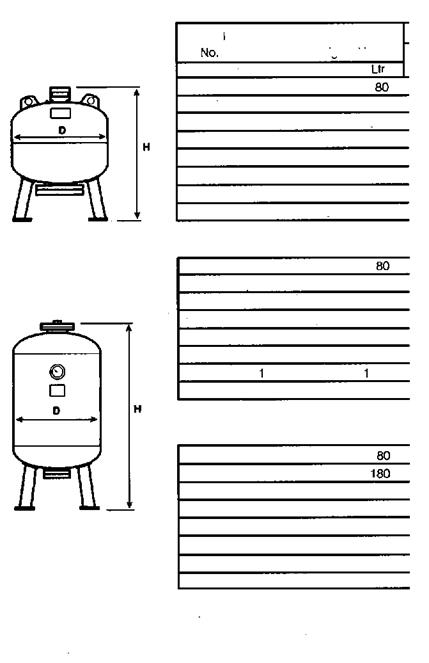

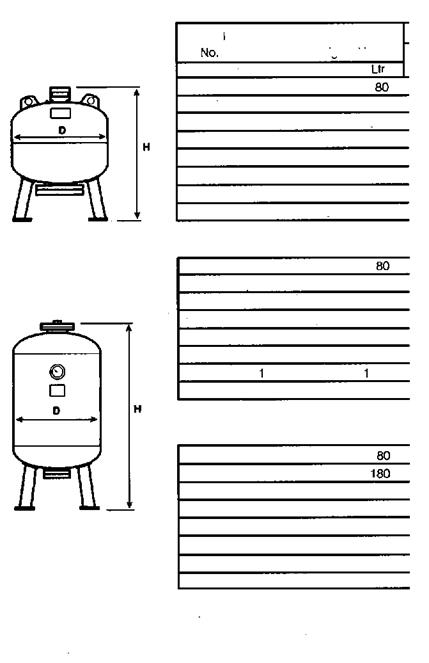

Model

|

Dimensions

|

Total

|

1,5/3,0 bar

|

2,0/3,5 bar

|

2,5/4,0 bar

|

System

|

Precharge

|

Shipping

|

|

No.

|

Diameter

|

Height

|

Volume

|

|

Drawdown

|

|

Connection

|

Pressure

|

Wt./Vol.

|

|

mm

|

mm

|

Ltr

|

Liter

|

Liter

|

Liter

|

FT

|

bar

|

KG/m3

|

|

WX 2,6

|

156

|

228

|

2.6

|

1,0

|

0,9

|

0,8

|

3/4

|

1,5

|

1,0/,005

|

|

WX4

|

156

|

302

|

4,1

|

1,5

|

1,4

|

1,2

|

3/4

|

1.5

|

1,5/,007

|

|

WX8

|

200

|

320

|

8

|

3,0

|

2.6

|

2,4

|

3/4

|

1,5

|

2,3/,02

|

|

WX 18

|

280

|

380

|

18

|

6,7

|

6,0

|

5,4

|

3/4

|

1,5.

|

4,1 / ,03

|

|

WX33

|

280

|

630

|

33

|

12,4

|

10,9

|

9,9

|

3/4

|

1,5

|

6,8 / ,05

|

|

|

FIGURE 8.27 ■ Specifications for in-line pressure tanks. (Courtesy of McGraw-Hill)

|

1,5/3,0 bar

|

2,0/3,5 bar

|

2,5/4,0 bar

|

System

Connection

|

Precharge

Pressure

|

Shipping

Wt./Vol.

|

|

Liter

|

Drawdown

Liter

|

Liter

|

|

FT

|

bar

|

KG /m3

|

|

30

|

27

|

24

|

2

|

3,5

|

59 / ,25

|

|

68

|

60

|

54

|

2

|

3,5

|

83 / ,39

|

|

113

|

99

|

90

|

2

|

3,5

|

155/,53

|

|

225

|

198

|

180

|

2

|

3,5

|

285/1,06

|

|

300

|

264

|

240

|

2

|

3,5

|

360/1,32

|

|

375

|

330

|

300

|

3

|

3,5

|

400 /1,96

|

|

600

|

528

|

480

|

3

|

3,5

|

540/2,74

|

|

750

|

660

|

600

|

3

|

3,5

|

780 / 3,59

|

|

30

|

27

|

24

|

2

|

3,5

|

59/,25

|

|

68

|

60

|

54

|

2

|

3,5

|

83 / ,39

|

|

113

|

99

|

90

|

2

|

3.5

|

155/,53

|

|

225

|

198

|

180

|

2

|

3,5

|

285 /1,06

|

|

300

|

264

|

240

|

2

|

3,5

|

360 /1,32

|

|

375

|

330

|

300

|

3

|

3,5

|

400 /1,96

|

|

600

|

528

|

480

|

3

|

3.5

|

540/2,74

|

|

750

|

660

|

600

|

3

|

3,5

|

7890/3,59

|

|

30

|

27

|

24

|

2

|

3,5

|

64 / ,25

|

|

68

|

60

|

54

|

2

|

3,5

|

102/,39

|

|

113

|

99

|

90

|

2

|

3,5

|

220 / ,53

|

|

225

|

198

|

180

|

2

|

3,5

|

400/1,06

|

|

300

|

264

|

240

|

2

|

3,5

|

505/1,32

|

|

375

|

330

|

300

|

3

|

3,5

|

560 / 1,96

|

|

600

|

528

|

480

|

3

|

3,5

|

756/2,74

|

|

750

|

660

|

600

|

3

|

3,5

|

1330/3,5

|

FIGURE 8.28 ■ (Continued) Specifications for pressure tanks with replaceable bladder designs. (Courtesy of McGraw-Hill)

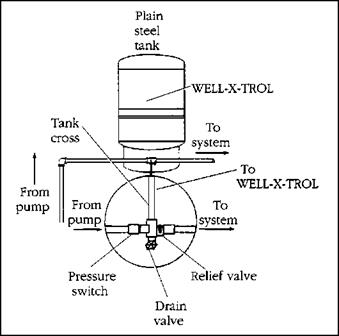

|

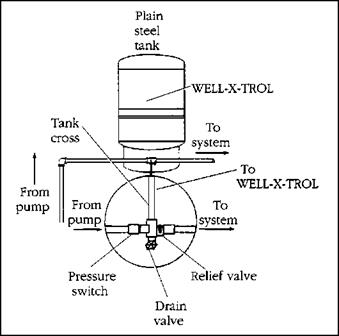

FIGURE 8.29 ■ Detail for a tank-tee set-up. (Courtesy of McGraw-Hill)

|

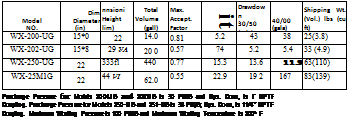

|

|

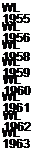

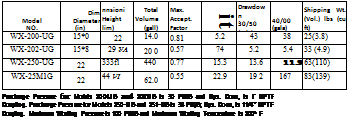

Dimensions

|

Total

|

Max.

|

Drawdown

|

|

ShipplRQ

|

|

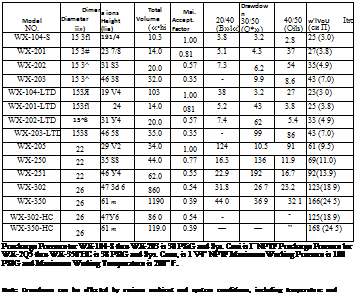

Model

|

Diameter

|

Height

|

Volume

|

Accept.

|

2W40

|

30/50

|

40/50

|

m (Vo i. >

|

|

No.

|

(ini)

|

(in)

|

(tali)

|

Factor

|

(gala)

|

(gall)

|

(gala)

|

H>i feu 44>

|

|

WX-103-PS

|

12 V2

|

11 VA

|

8.6

|

028

|

3 1

|

2.7

|

22

|

20(2.4}

|

|

WX 200-PS

|

17 W

|

15 *8

|

140

|

0.31

|

5.2

|

43

|

38

|

29(4 0)

|

Precharge Pressure is 30 PSIG and Sys. Conn, is *4“ NPTM Filling lor 103-PS and i" NPTF Coupling lor 2Q0-PS. Maximum Working Pressure is 100 PSIG and Maximum Working Temperalure is 200" F.

|

|

|

|

|

FIGURE 8.31 ■ Underground pressure tank specifications. (Courtesy of McGraw-Hill)

|

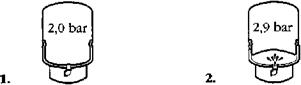

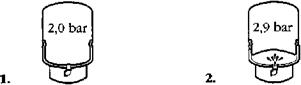

When the pump starts, water enters the WELL-X-TROL as system pressure passes the minimum pressure precharge. Only usable water is stored.

|

|

|

WELL-X-TROL has a sealed-in air chamber that is pre-pfessurized before it leaves our factory. Air and water do not mix eliminating any chance of “waterlogging” through loss of air to system

|

|

|

|

When water is demanded, pressure in the air chamber forces water into the system. Since WELL-X-TROL does not waterlog and consistently delivers the maximum usable water, minimum pump starts are assured.

|

|

|

|

|

Maximum starts per 24 hr. day

|

Motor rating

|

Single phase

|

Three phase

|

|

Up to 3A hp

|

300

|

300

|

|

1 hp thru 5 hp

|

100

|

300

|

|

7 У2 hp thru 30 hp

|

50

|

100

|

|

40 hp and over

|

|

100

|

|

|

|

|

|

|

|

|

Operating pressure—psig

discharge 20/40 30/50 40/60

|

rate gpm (approx.) 2.5

|

ESP I

|

ESP II

|

ESP I

|

ESP II

|

ESP I

|

ESP II

|

|

WX-104

|

WX-201

|

WX-104

|

WX-202

|

WX-104

|

WX-202

|

|

5

|

WX-201

|

WX-205

|

WX-202

|

WX-205

|

WX-202

|

WX-250

|

|

7

|

WX-202

|

WX-250

|

WX-203

|

WX-251

|

WX-205

|

WX-251

|

|

10

|

WX-203

|

WX-251

|

WX-205

|

WX-302

|

WX-250

|

WX-302

|

|

12

|

WX-205

|

WX-302

|

WX-250

|

WX-302

|

WX-251

|

WX-350

|

|

15

|

WX-250

|

WX-302

|

WX-251

|

WX-350

|

WX-251

|

WX-350

|

|

20

|

WX-251

|

WX-350

|

WX-302

|

(2JWX-251

|

WX-302

|

(2)WX-302

|

|

25

|

WX-302

|

(2JWX-302

|

WX-302

|

(2)WX-302

|

WX-350

|

(3)WX-251

|

|

30

|

WX-302

|

(2)WX-302

|

WX-350

|

(DWX-302

|

WX-350

|

(2)WX-350

|

|

35

|

WX-350

|

(DWX-302

|

WX-350

|

(DWX-350

(2)WX-350

|

(2JWX-251

|

(3)WS-302

|

|

40

|

WX-350

|

(DWX-350

(2)WX-350

|

(2)WX-251

|

(3)WX-302

|

(2)WX-302

|

(DWX-302

|

|

|

|

|

|

|

(2)WX-350

|

|

|

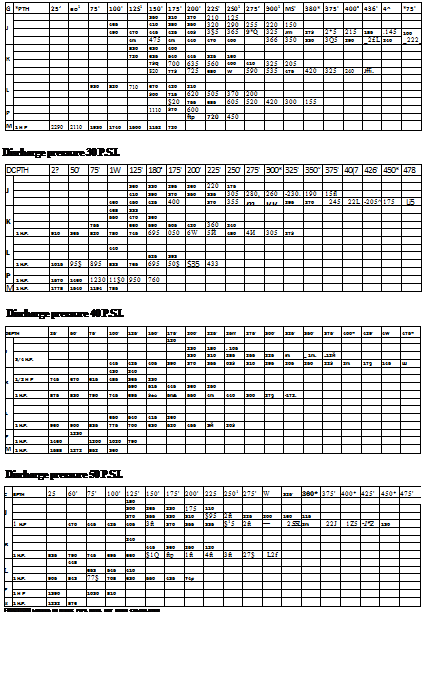

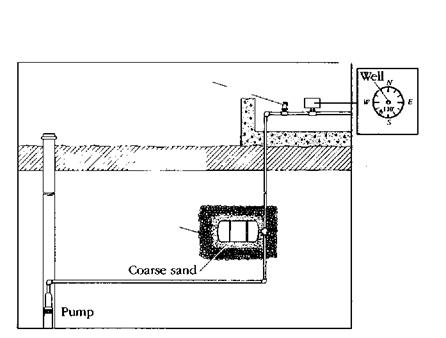

FIGURE 8.34 ■ Sizing and selection information for perssure tanks. (Courtesy of McGraw-Hill)

FIGURE 8.24 ■ An underground installation of a pressure tank. (Courtesy of McGraw-Hill)

FIGURE 8.24 ■ An underground installation of a pressure tank. (Courtesy of McGraw-Hill)

![]()

![]()

Leave a reply