PLASTIC PIPE FOR DRAINS & VENTS

Plastic pipe for drains and vents is very common in modern plumbing. Polyvinyl Chloride Plastic Pipe (PVC) is probably used more often than any other type of drainage or vent pipe (Fig. 11.26). This type of pipe is strong and resistive to a variety of acids and bases. PVC pipe can be used with water, gas, and drainage systems, but it is not rated for use with hot water. I’ve found this type of pipe to be sensitive to dirt and water when joints are being

|

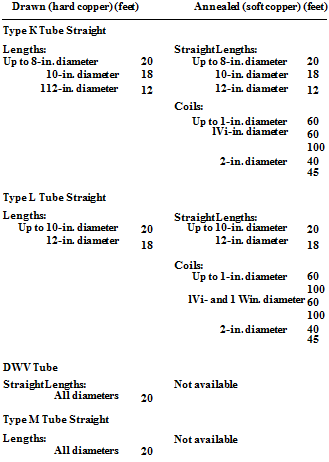

FIGURE 11.22 ■ Available lengths of copper plumbing tube. [Courtesy of McGraw-Hill)

made. The areas being joined should be dry, clean, and primed prior to solvent welding. Also, PVC becomes brittle in cold weather and should not be dropped on hard surfaces.

Acrylonitrile Butadiene Styrene (ABS) pipe is the drainage pipe of preference for me. However, I do use more PVC than ABS at this point in my

|

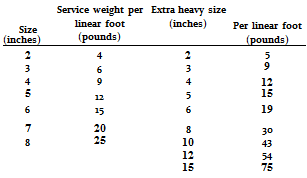

FIGURE 11.24 ■ Weight of cast-iron soil and pipe. (Courtesy of McGraw-Hill)

career. When plastic drainage and vent piping became popular, I cut my teeth on ABS pipe. But, PVC pipe is less expensive in most regions and enjoys a less-destructive rating in the case of fires, so most of the industry, that I know of, has moved to PVC. I like ABS because of its durability and its ease of working with. This pipe is so strong that I’ve seen loaded dump trucks run over a section of ABS on a project and never crush the pipe!

career. When plastic drainage and vent piping became popular, I cut my teeth on ABS pipe. But, PVC pipe is less expensive in most regions and enjoys a less-destructive rating in the case of fires, so most of the industry, that I know of, has moved to PVC. I like ABS because of its durability and its ease of working with. This pipe is so strong that I’ve seen loaded dump trucks run over a section of ABS on a project and never crush the pipe!

Leave a reply