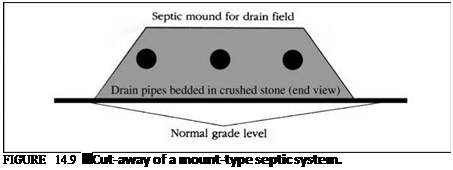

MOUND SYSTEMS

Mound systems, as you might suspect, are septic systems that are constructed in mounds that rise above the natural topography. This is done to compensate for high water tables and soils with slow absorption rates. Due to the amount of fill material to create a mound, the cost is naturally higher than it would be for a bed system.

|

Coarse gravel is normally used to build a septic mound. The stone is piled on top of the existing ground. However, topsoil is removed before the stone

is installed. When a mound is built, it contains suitable fill material, an absorption area, a distribution network, a cap, and topsoil. Due to the raised height, a mound system depends on either pumping or siphonic action to work properly. Essentially, effluent is either pumped or siphoned into the distribution network.

As the effluent is passing through the coarse gravel and infiltrating the fill material, treatment of the wastewater occurs. This continues as the liquid passes through the unsaturated zone of the natural soil. The purpose of the cap is to retard frost action, deflect precipitation, and to retain moisture that will stimulate the growth of ground cover.

Mounds should be used only in areas that drain well. The topography can be level or slightly sloping. The amount of slope allowable depends on the perk rate. For example, soil that perks at a rate of one inch every sixty minutes or less, should not have a slope of more than six percent if a mound system is to be installed. If the soil absorbs water from a perk test faster than one inch in one hour, the slope could be increased to twelve percent. These numbers are only examples. A professional who designs a mound system will set the true criteria for slope values. Ideally, about two feet of unsaturated soil should exist between the original soil surface and the seasonally saturated topsoil. There should be three to five feet of depth to the impermeable barrier. An overall range of perk rate could go as high as one inch in two hours, but this, of course, is subject to local approval. Perk tests for this type of system are best when done at a depth of about 20 inches. However, they can be performed at shallow depths of only 12 inches. Again, you must consult and follow local requirements.

Mounds should be used only in areas that drain well. The topography can be level or slightly sloping. The amount of slope allowable depends on the perk rate. For example, soil that perks at a rate of one inch every sixty minutes or less, should not have a slope of more than six percent if a mound system is to be installed. If the soil absorbs water from a perk test faster than one inch in one hour, the slope could be increased to twelve percent. These numbers are only examples. A professional who designs a mound system will set the true criteria for slope values. Ideally, about two feet of unsaturated soil should exist between the original soil surface and the seasonally saturated topsoil. There should be three to five feet of depth to the impermeable barrier. An overall range of perk rate could go as high as one inch in two hours, but this, of course, is subject to local approval. Perk tests for this type of system are best when done at a depth of about 20 inches. However, they can be performed at shallow depths of only 12 inches. Again, you must consult and follow local requirements.

Leave a reply