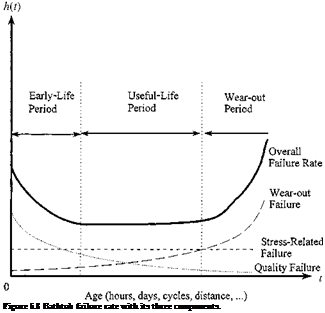

Typical hazard functions

The failure rate for many systems or components has a bathtub shape, as shown in Fig. 5.8, in that three distinct life periods can be identified (Harr, 1987). They are the early-life (or infant mortality) period, useful-life period, and wear-out – life period. Kapur (1989b) differentiates three types of failure that result in the bathtub type of total failure rate, as indicated in Fig. 5.8. It is interesting to note that the failure rate in the early-life period is higher than during the useful-life period and has a decreasing trend with age. In this early-life period, quality failures and stress-related failures dominate, with little contribution from wear-out failures. During the useful-life period, all three types of failures contribute to the potential failure of the system or component, and the overall failure rate remains more or less constant over time. From Example 5.1, the exponential distribution could be used as the failure density function for the useful-life period. In the later part of life, the overall failure rate increases with age. In this life stage, wear-out failures and stress-related failures are the main contributors, and wear-out becomes an increasingly dominating factor for the failure of the system with age.

Quality failures, also called break-in failures (Wunderlich, 1993, 2004), are mainly related to the construction and production of the system, which could be caused by poor construction and manufacturing, poor quality control and workmanship, use of substandard materials and parts, improper installation, and human error. Failure rate of this type generally decreases with age. Stress – related failures generally are referred to as chance failures, which occur when loads on the system exceed its resistance, as described in Chap. 4. Possible causes of stress-related failures include insufficient safety factors, occurrence

|

of higher than expected loads or lower than expected random strength, misuse, abuse, and/or an act of God. Wear-out failures are caused primarily by aging; wear; deterioration and degradation in strength; fatigue, creep, and corrosion; or poor maintenance, repair, and replacement.

The failure of the 93-m-high Teton Dam in Idaho in 1976 was a typical example of break-in failure during the early-life period (Arthur, 1977; Jansen, 1988). The dam failed while the reservoir was being filled for the first time. Four hours after the first leakage was detected, the dam was fully breached. There are other examples of hydraulic structure failures during different stages of their service lives resulting from a variety of causes. For examples, in 1987 the foundation of a power plant on the Mississippi River failed after a 90-year service life (Barr and Heuer, 1989), and in the summer of 1993 an extraordinary sequence of storms caused the breach of levees in many parts along the Mississippi River. The failures and their impacts can be greatly reduced if proper maintenance and monitoring are actively implemented.

Leave a reply