Semirigid Systems

The box-beam (weak-post) system (Fig. 6.16) achieves its resistance through the combined flexural and tensile resistance of the box beam. Posts near the impact point are designed to break or tear away and distribute the impact force to adjacent posts. This system meets TL-3. The system is sensitive to mounting height and irregularities in terrain.

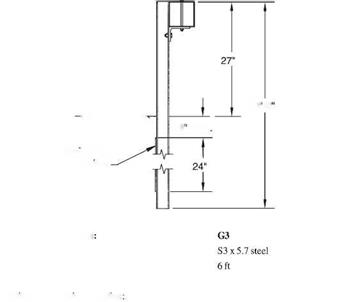

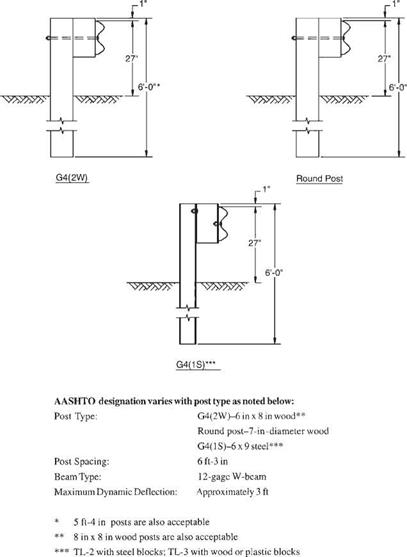

The blocked-out W-beam (strong-post) system (Fig. 6.17) is the most common barrier. The blockout or offset of the rail from the post minimizes vehicle snagging and reduces likelihood that a vehicle would vault over the barrier. The system is classified as TL-2 or TL-3, depending upon the type of blocks. As with all strong-post systems, resistance is developed by a combination of the tensile and flexural resistance of the rail and the flexural and shear strength of the post. Dynamic deflections are less than those of flexible systems. Bolt washers on the posts can be eliminated on this and other strong-post systems; they are not needed for strength, and it is desirable for the rail to break away as the post rotates downward. Strong-post systems tend to remain functional after moderate collisions, so that immediate repairs are not necessary.

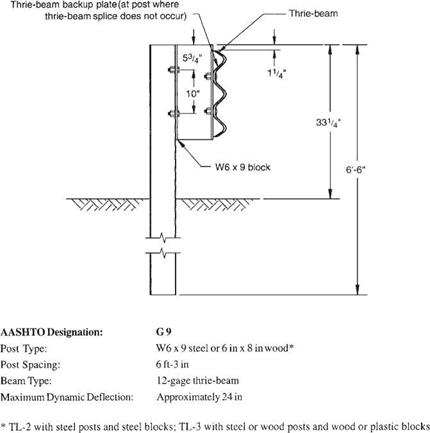

The blocked-out thrie-beam (strong-post) system (Fig. 6.18) is similar to the preceding system, but it has a deeper, stiffer, three-corrugation rail. This makes it less prone to damage during impact, allows higher rail mounting, and is better able to contain larger vehicles under some impact conditions. The system is classified as TL-2 or TL-3, depending upon the type of blocks.

The modified thrie-beam system (Fig. 6.19) has a steel blockout with a triangular notch cut from its web. This allows the lower part of the beam and the face of the spacer block to bend in during impact, causes the rail face to remain nearly vertical as the post is bent back, and reduces likelihood that a vehicle would roll over the barrier.

5-3

![]() УУАУАУА4

УУАУАУА4

Soil Plate

Typical

AASHTO Designation

Post Type: Post Spacing:

Post Type: Post Spacing:

|

FIGURE 6.17 Blocked-out W-beam (strong-post) roadside barrier. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. (From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission) |

Also, bolt washers have been eliminated on the posts, as discussed previously. The modifications have resulted in a TL-4 rating. Repair costs of either thrie-beam system should be considerably less than for other metal barrier systems, because damage tends to be slight in shallow-angle impacts. Also, it is considered easier to install and maintain than a W-beam system with rub rail.

|

FIGURE 6.18 Blocked-out thrie-beam (strong-post) roadside barrier. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. (From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission) |

The steel-backed timber-rail system (Fig. 6.20) is an aesthetic alternative to conventional systems, often selected for use along park roads. It has been successfully tested to TL-3.

Leave a reply