SELECTION OF ROADSIDE BARRIERS

In most cases, the selection of a roadside barrier should be made on the basis of the system that will provide the required degree of shielding at the lowest cost. The lowest cost should be based on a life-cycle cost analysis, considering initial and maintenance costs

|

|

None

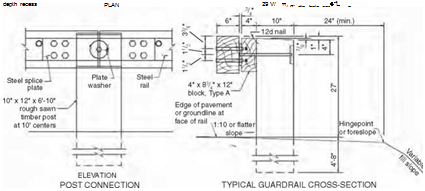

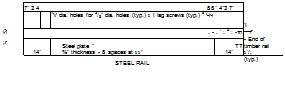

10 in x 12 in x 7 in rough-sawn timber 6 in x 10 in timber with steel plate backing 27 in

FIGURE 6.20 Steel-backed wood-rail roadside barrier. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. (From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission) and project life. Factors that should be considered in making the selection are summarized in Table 6.3. The most important decision is the performance level required. In general, TL-2 or TL-3 barriers are satisfactory for most locations, but higher-performance barriers (TL-4 or greater) should be considered for locations with poor geometries, high traffic volumes and speeds, and concentrations of heavy truck traffic. The deflection characteristics of the barrier must be considered in relation to the available space. Some systems can be modified to decrease deflections by decreasing post spacing or increasing the

|

(a) (b)

AASHTO Designation: MBS

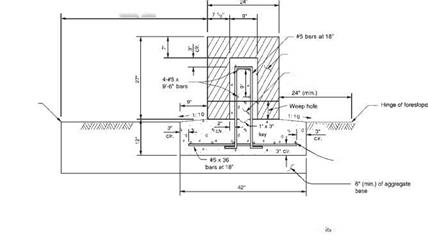

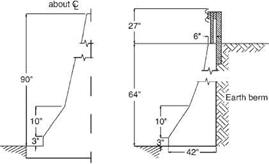

The 32-in-high concrete safety shape was initially installed primarily as a median barrier, but has become commonly used as both a bridge railing and a roadside barrier, Most of these barriers use the standard New Jersey shape; any extension in barrier height occurs above the slope break point. Several stales extend the upper stem to serve as a maintenance-free glare screen. The two designs shown above are the extreme heights to which roadside barriers have been constructed— both along ramps with a history of truck accidents.

FIGURE 6.21 Variations of concrete safety shape for roadside barrier in severe applications showing (a) symmetrical form and (b) earth-backed installation. Conversion: 1 in = 25.4 mm. (From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission)

number of rails. A computer program, Analysis of Roadside Design (NARD), is available for predicting maximum deflections for blocked-out W-beam and thrie-beam systems with different post spacings and single or double rails. On all systems, data on impact performance and maintenance costs should be tabulated and made available to provide better information for the selection of roadside barriers.

Variable offset

Stone masonry facing

Concrete со rewall

Edge of. pavement

6-#5 x 9′-4"

bars (spaced as shown)

AASHTO Designation: None

![]() This barrier consists of a reinforced concrete core faced with stone rubble masonry. Designed for use in scenic areas, combine to make it an effective barrier for use on parkways and similar facilities.

This barrier consists of a reinforced concrete core faced with stone rubble masonry. Designed for use in scenic areas, combine to make it an effective barrier for use on parkways and similar facilities.

|

Criterion |

Comments |

|

Performance capability |

Barrier must be structurally able to contain and redirect design vehicle. |

|

Deflection |

Expected deflection of barrier should not exceed available room to deflect. |

|

Site conditions |

Slope approaching the barrier, and distance from traveled way, may preclude use of some barrier types. |

|

Compatibility |

Barrier must be compatible with planned end anchor and capable of transition to other barrier systems (such as bridge railing). |

|

Cost Maintenance |

Standard barrier systems are relatively consistent in cost, but high-performance railing can cost significantly more. |

|

Routine |

Few systems require a significant amount of routine maintenance. |

|

Collision |

Generally, flexible or semirigid systems require significantly more maintenance after a collision than rigid or high-performance railings. |

|

Materials storage |

The fewer different systems used, the fewer inventory items or the less storage space required. |

|

Simplicity |

Simpler designs, besides costing less, are more likely to be reconstructed properly by field personnel. |

|

Aesthetics |

Occasionally, barrier aesthetics is an important consideration in selection. |

|

Field experience |

The performance and maintenance requirements of existing systems should be monitored to identify problems that could be lessened or eliminated by using a different barrier type. |

Source: From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and

2006, with permission.

Leave a reply