Roadbed Soil Resilient Modulus

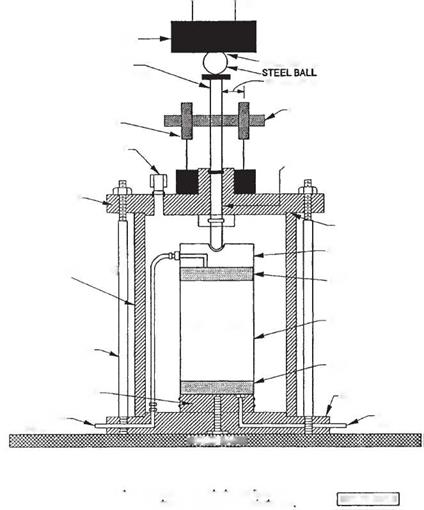

The resilient modulus is a measure of the ability of a soil or granular base to resist permanent deformation under repeated loading. Many soils are stress-dependent. As the stress level increases, these soils will behave in a nonlinear fashion. Fine-grain soils tend to be stress-softening, whereas granular soils tend to be stress-hardening. Laboratory procedures for determining resilient modulus have been published by AASHTO as test method T307, or NCHRP as test method 1-38A. A typical setup for the laboratory test is shown in Fig. 3.9. The stress due to the repeated load applied through the load actuator is the deviator stress and is intended to duplicate the effect of loads passing over a section of pavement. The confining stress within the chamber is intended to duplicate the confinement of the soil within the subgrade. A typical load-response curve is shown in Fig. 3.10. As shown, the resilient modulus (MR) is the ratio of deviator stress to strain in the elastic range.

The laboratory procedures for determining resilient modulus are complex and timeconsuming. Many equations have been developed relating the resilient modulus to soil properties that are more easily determined. One such property is the California

|

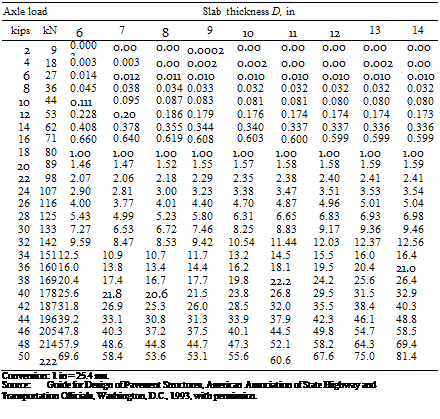

TABLE 3.11 Axle Load Equivalency Factors for Rigid Pavements, Tandem Axles, and pt of 2.0

Conversion: 1 in = 25.4 mm. |

|

Axle load |

Slab thickness D, in |

|||||||||

|

kips |

kN |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

2 |

9 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

|

4 |

18 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

|

6 |

27 |

0.0010 |

0.0009 |

0.0009 |

0.0009 |

0.0009 |

0.0009 |

0.0009 |

0.0009 |

0.0009 |

|

8 |

36 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

|

10 |

44 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

|

12 |

53 |

0.010 |

0.010 |

0.009 |

0.009 |

0.009 |

0.009 |

0.009 |

0.009 |

0.009 |

|

14 |

62 |

0.018 |

0.017 |

0.017 |

0.016 |

0.016 |

0.016 |

0.016 |

0.016 |

0.016 |

|

16 |

71 |

0.030 |

0.029 |

0.028 |

0.027 |

0.027 |

0.027 |

0.027 |

0.027 |

0.027 |

|

18 |

80 |

0.047 |

0.045 |

0.044 |

0.044 |

0.043 |

0.043 |

0.043 |

0.043 |

0.043 |

|

20 |

89 |

0.072 |

0.069 |

0.067 |

0.066 |

0.066 |

0.066 |

0.066 |

0.066 |

0.066 |

|

22 |

98 |

0.105 |

0.101 |

0.099 |

0.098 |

0.097 |

0.097 |

0.097 |

0.097 |

0.097 |

|

24 |

107 |

0.149 |

0.144 |

0.141 |

0.139 |

0.139 |

0.138 |

0.138 |

0.138 |

0.138 |

|

26 |

116 |

0.205 |

0.199 |

0.195 |

0.194 |

0.193 |

0.192 |

0.192 |

0.192 |

0.192 |

|

28 |

125 |

0.276 |

0.270 |

0.265 |

0.263 |

0.262 |

0.262 |

0.262 |

0.262 |

0.261 |

|

30 |

133 |

0.364 |

0.359 |

0.354 |

0.351 |

0.350 |

0.349 |

0.349 |

0.349 |

0.349 |

|

32 |

142 |

0.472 |

0.468 |

0.463 |

0.460 |

0.459 |

0.458 |

0.458 |

0.458 |

0.458 |

|

34 |

151 |

0.603 |

0.600 |

0.596 |

0.594 |

0.593 |

0.592 |

0.592 |

0.592 |

0.592 |

|

36 |

160 |

0.759 |

0.758 |

0.757 |

0.756 |

0.755 |

0.755 |

0.755 |

0.755 |

0.755 |

|

38 |

169 |

0.946 |

0.947 |

0.949 |

0.950 |

0.951 |

0.951 |

0.951 |

0.951 |

0.951 |

|

40 |

178 |

1.17 |

1.17 |

1.18 |

1.18 |

1.18 |

1.18 |

1.18 |

1.18 |

1.19 |

|

42 |

187 |

1.42 |

1.43 |

1.44 |

1.45 |

1.46 |

1.46 |

1.46 |

1.46 |

1.46 |

|

44 |

196 |

1.73 |

1.73 |

1.75 |

1.77 |

1.78 |

1.78 |

1.79 |

1.79 |

1.79 |

|

46 |

205 |

2.08 |

2.07 |

2.10 |

2.13 |

2.15 |

2.16 |

2.16 |

2.16 |

2.17 |

|

48 |

214 |

2.48 |

2.47 |

2.51 |

2.55 |

2.58 |

2.59 |

2.60 |

2.60 |

2.61 |

|

50 |

222 |

2.95 |

2.92 |

2.97 |

3.03 |

3.07 |

3.09 |

3.10 |

3.11 |

3.11 |

|

52 |

231 |

3.48 |

3.44 |

3.50 |

3.58 |

3.63 |

3.66 |

3.68 |

3.69 |

3.69 |

|

54 |

240 |

4.09 |

4.03 |

4.09 |

4.20 |

4.27 |

4.31 |

4.33 |

4.35 |

4.35 |

|

56 |

249 |

4.78 |

4.69 |

4.76 |

4.89 |

4.99 |

5.05 |

5.08 |

5.09 |

5.10 |

|

58 |

258 |

5.57 |

5.44 |

5.51 |

5.66 |

5.79 |

5.87 |

5.91 |

5.94 |

5.95 |

|

60 |

267 |

6.45 |

6.29 |

6.35 |

6.53 |

6.69 |

6.79 |

6.85 |

6.88 |

6.90 |

|

62 |

276 |

7.43 |

7.23 |

7.28 |

7.49 |

7.69 |

7.82 |

7.90 |

7.94 |

7.97 |

|

64 |

285 |

8.54 |

8.28 |

8.32 |

8.55 |

8.80 |

8.97 |

9.07 |

9.13 |

9.16 |

|

66 |

294 |

9.76 |

9.46 |

9.48 |

9.73 |

10.02 |

10.24 |

10.37 |

10.44 |

10.48 |

|

68 |

302 |

11.1 |

10.8 |

10.8 |

11.0 |

11.4 |

11.6 |

11.8 |

11.9 |

12.0 |

|

70 |

311 |

12.6 |

12.2 |

12.2 |

12.5 |

12.8 |

13.2 |

13.4 |

13.5 |

13.6 |

|

72 |

320 |

14.3 |

13.8 |

13.7 |

14.0 |

14.5 |

14.9 |

15.1 |

15.3 |

15.4 |

|

74 |

329 |

16.1 |

15.5 |

15.4 |

15.7 |

16.2 |

16.7 |

17.0 |

17.2 |

17.3 |

|

76 |

338 |

18.2 |

17.5 |

17.3 |

17.6 |

18.2 |

18.7 |

19.1 |

19.3 |

19.5 |

|

78 |

347 |

20.4 |

19.6 |

19.4 |

19.7 |

20.3 |

20.9 |

21.4 |

21.7 |

21.8 |

|

80 |

356 |

22.8 |

21.9 |

21.6 |

21.9 |

22.6 |

23.3 |

23.8 |

24.2 |

24.4 |

|

82 |

365 |

25.4 |

24.4 |

24.1 |

24.4 |

25.0 |

25.8 |

26.5 |

26.9 |

27.2 |

|

84 |

374 |

28.3 |

27.1 |

26.7 |

27.0 |

27.7 |

28.6 |

29.4 |

29.9 |

30.2 |

|

86 |

383 |

31.4 |

30.1 |

29.6 |

29.9 |

30.7 |

31.6 |

32.5 |

33.1 |

33.5 |

|

88 |

391 |

34.8 |

33.3 |

32.8 |

33.0 |

33.8 |

34.8 |

35.8 |

36.6 |

37.1 |

|

90 |

400 |

38.5 |

36.8 |

36.2 |

36.4 |

37.2 |

38.3 |

39.4 |

40.3 |

40.9 |

|

Conversion: 1 in = 25.4 mm. |

|

TABLE 3.13 Axle Load Equivalency Factors for Rigid Pavements, Single Axles, and pt of 2.5

Conversion: 1 in = 25.4 mm. Source: Guide for Design of Pavement Structures, American Association of State Highway and Transportation Officials, Washington, D. C., 1993, with permission. |

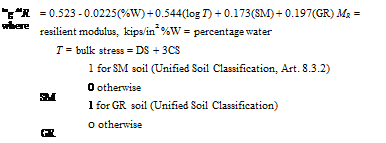

Bearing Ratio (CBR). Common equations using CBR to calculate resilient modulus values include the following:

E (lb/in2) = 1500 CBR (Shell Oil Co.)

E (lb/in2) = 5409 CBR0 711 (U. S. Army Waterway Experiment Station)

E (lb/in2) = 2550 CBR0 64 (Transport and Road Research Laboratory, England)

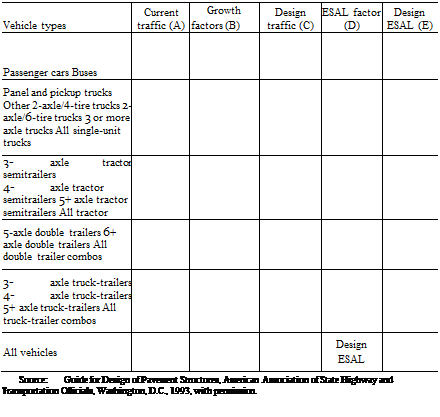

(See “Pavement Deflection Analysis,” FHWA Report HI-94-021, NHI, February 1994.) More detailed equations have been developed by correlating laboratory results with fundamental soil properties. R. F. Carmichael III and E. Stuart (“Predicting Resilient Modulus: A Study to Determine the Mechanical Properties of Subgrade Soils,” Transportation Research Record 1043, Transportation Research Board, National Research Council, Washington, D. C., 1985) developed the following models for the U. S. Forest Service:

|

Axle load |

Slab thickness D, in |

|||||||||

|

kips |

kN |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

2 |

9 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

|

4 |

18 |

0.0006 |

0.0006 |

0.0005 |

0.0005 |

0.0005 |

0.0005 |

0.0005 |

0.0005 |

0.0005 |

|

6 |

27 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

|

8 |

36 |

0.007 |

0.006 |

0.006 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

|

10 |

44 |

0.015 |

0.014 |

0.013 |

0.013 |

0.012 |

0.012 |

0.012 |

0.012 |

0.012 |

|

12 |

53 |

0.031 |

0.028 |

0.026 |

0.026 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

|

14 |

62 |

0.057 |

0.052 |

0.049 |

0.048 |

0.047 |

0.047 |

0.047 |

0.047 |

0.047 |

|

16 |

71 |

0.097 |

0.089 |

0.084 |

0.082 |

0.081 |

0.081 |

0.080 |

0.080 |

0.080 |

|

18 |

80 |

0.155 |

0.143 |

0.136 |

0.133 |

0.132 |

0.131 |

0.131 |

0.131 |

0.131 |

|

20 |

89 |

0.234 |

0.220 |

0.211 |

0.206 |

0.204 |

0.203 |

0.203 |

0.203 |

0.203 |

|

22 |

98 |

0.340 |

0.325 |

0.313 |

0.308 |

0.305 |

0.304 |

0.303 |

0.303 |

0.303 |

|

24 |

107 |

0.475 |

0.462 |

0.450 |

0.444 |

0.441 |

0.440 |

0.439 |

0.439 |

0.439 |

|

26 |

116 |

0.644 |

0.637 |

0.627 |

0.622 |

0.620 |

0.619 |

0.618 |

0.618 |

0.618 |

|

28 |

125 |

0.855 |

0.854 |

0.852 |

0.850 |

0.850 |

0.850 |

0.849 |

0.849 |

0.849 |

|

30 |

133 |

1.11 |

1.12 |

1.13 |

1.14 |

1.14 |

1.14 |

1.14 |

1.14 |

1.14 |

|

32 |

142 |

1.43 |

1.44 |

1.47 |

1.49 |

1.50 |

1.51 |

1.51 |

1.51 |

1.51 |

|

34 |

151 |

1.82 |

1.82 |

1.87 |

1.92 |

1.95 |

1.96 |

1.97 |

1.97 |

1.97 |

|

36 |

160 |

2.29 |

2.27 |

2.35 |

2.43 |

2.48 |

2.51 |

2.52 |

2.52 |

2.53 |

|

38 |

169 |

2.85 |

2.80 |

2.91 |

3.03 |

3.12 |

3.16 |

3.18 |

3.20 |

3.20 |

|

40 |

178 |

3.52 |

3.42 |

3.55 |

3.74 |

3.87 |

3.94 |

3.98 |

4.00 |

4.01 |

|

42 |

187 |

4.32 |

4.16 |

4.30 |

4.55 |

4.74 |

4.86 |

4.91 |

4.95 |

4.96 |

|

44 |

196 |

5.26 |

5.01 |

5.16 |

5.48 |

5.75 |

5.92 |

6.01 |

6.06 |

6.09 |

|

46 |

205 |

6.36 |

6.01 |

6.14 |

6.53 |

6.90 |

7.14 |

7.28 |

7.36 |

7.40 |

|

48 |

214 |

7.64 |

7.16 |

7.27 |

7.73 |

8.21 |

8.55 |

8.75 |

8.86 |

8.92 |

|

50 |

222 |

9.11 |

8.50 |

8.55 |

9.07 |

9.68 |

10.14 |

10.42 |

10.58 |

10.66 |

|

52 |

231 |

10.8 |

10.0 |

10.0 |

10.6 |

11.3 |

11.9 |

12.3 |

12.5 |

12.7 |

|

54 |

240 |

12.8 |

11.8 |

11.7 |

12.3 |

13.2 |

13.9 |

14.5 |

14.8 |

14.9 |

|

56 |

249 |

15.0 |

13.8 |

13.6 |

14.2 |

15.2 |

16.2 |

16.8 |

17.3 |

17.5 |

|

58 |

258 |

17.5 |

16.0 |

15.7 |

16.3 |

17.5 |

18.6 |

19.5 |

20.1 |

20.4 |

|

60 |

267 |

20.3 |

18.5 |

18.1 |

18.7 |

20.0 |

21.4 |

22.5 |

23.2 |

23.6 |

|

62 |

276 |

23.5 |

21.4 |

20.8 |

21.4 |

22.8 |

24.4 |

25.7 |

26.7 |

27.3 |

|

64 |

285 |

27.0 |

24.6 |

23.8 |

24.4 |

25.8 |

27.7 |

29.3 |

30.5 |

31.3 |

|

66 |

294 |

31.0 |

28.1 |

27.1 |

27.6 |

29.2 |

31.3 |

33.2 |

34.7 |

35.7 |

|

68 |

302 |

35.4 |

32.1 |

30.9 |

31.3 |

32.9 |

35.2 |

37.5 |

39.3 |

40.5 |

|

70 |

311 |

40.3 |

36.5 |

35.0 |

35.3 |

37.0 |

39.5 |

42.1 |

44.3 |

45.9 |

|

72 |

320 |

45.7 |

41.4 |

39.6 |

39.8 |

41.5 |

44.2 |

47.2 |

49.8 |

51.7 |

|

74 |

329 |

51.7 |

46.7 |

44.6 |

44.7 |

46.4 |

49.3 |

52.7 |

55.7 |

58.0 |

|

76 |

338 |

58.3 |

52.6 |

50.2 |

50.1 |

51.8 |

54.9 |

58.6 |

62.1 |

64.8 |

|

78 |

347 |

65.5 |

59.1 |

56.3 |

56.1 |

57.7 |

60.9 |

65.0 |

69.0 |

72.3 |

|

80 |

356 |

73.4 |

66.2 |

62.9 |

62.5 |

64.2 |

67.5 |

71.9 |

76.4 |

80.2 |

|

82 |

365 |

82.0 |

73.9 |

70.2 |

69.6 |

71.2 |

74.7 |

79.4 |

84.4 |

88.8 |

|

84 |

374 |

91.4 |

82.4 |

78.1 |

77.3 |

78.9 |

82.4 |

87.4 |

93.0 |

98.1 |

|

86 |

383 |

102. |

92. |

87. |

86. |

87. |

91. |

96. |

102. |

108. |

|

88 |

391 |

113. |

102. |

96. |

95. |

96. |

100. |

105. |

112. |

119. |

|

90 |

400 |

125. |

112. |

106. |

105. |

106. |

110. |

115. |

123. |

130. |

|

Conversion: 1 in = 25.4 mm. |

|

TABLE 3.15 Axle Load Equivalency Factors for Rigid Pavements, Triple Axles, and pt of 2.5

Conversion: 1 in = 25.4 mm. |

Cohesive soils:

MR = 37.431 – 0.4566(PI) – 0.6179(%W) – 0.1424(S200) +

![]() 0.1791(CS) – 0.3248(DS) + 36.422(CH) + 17.097(MH)

0.1791(CS) – 0.3248(DS) + 36.422(CH) + 17.097(MH)

resilient modulus, kips/in2 plasticity index percentage water

resilient modulus, kips/in2 plasticity index percentage water

percentage passing the no. 200 sieve confining stress, lb/in2 deviator stress, lb/in2

1 for CH soil (Unified Soil Classification, Art. 8.3.2)

0 otherwise

1 for MH soil (Unified Soil Classification)

0 otherwise

|

TABLE 3.17 Axle Load Equivalency Factors for Rigid Pavements, Tandem Axles, andpt of 3.0

Conversion: 1 in = 25.4 mm. |

|

Axle load |

Slab thickness D, in |

|||||||||

|

kips |

kN |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

2 |

9 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

0.0001 |

|

4 |

18 |

0.0004 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

0.0003 |

|

6 |

27 |

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

|

8 |

36 |

0.003 |

0.003 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

0.002 |

|

10 |

44 |

0.007 |

0.006 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

|

12 |

53 |

0.013 |

0.011 |

0.010 |

0.009 |

0.009 |

0.009 |

0.009 |

0.009 |

0.009 |

|

14 |

62 |

0.023 |

0.020 |

0.018 |

0.017 |

0.017 |

0.016 |

0.016 |

0.016 |

0.016 |

|

16 |

71 |

0.039 |

0.033 |

0.030 |

0.028 |

0.028 |

0.027 |

0.027 |

0.027 |

0.027 |

|

18 |

80 |

0.061 |

0.052 |

0.047 |

0.045 |

0.044 |

0.044 |

0.043 |

0.043 |

0.043 |

|

20 |

89 |

0.091 |

0.078 |

0.071 |

0.068 |

0.067 |

0.066 |

0.066 |

0.066 |

0.066 |

|

22 |

98 |

0.132 |

0.114 |

0.104 |

0.100 |

0.098 |

0.097 |

0.097 |

0.097 |

0.097 |

|

24 |

107 |

0.183 |

0.161 |

0.148 |

0.143 |

0.140 |

0.139 |

0.139 |

0.138 |

0.138 |

|

26 |

116 |

0.246 |

0.221 |

0.205 |

0.198 |

0.195 |

0.193 |

0.193 |

0.192 |

0.192 |

|

28 |

125 |

0.322 |

0.296 |

0.277 |

0.268 |

0.265 |

0.263 |

0.262 |

0.262 |

0.262 |

|

30 |

133 |

0.411 |

0.387 |

0.367 |

0.357 |

0.353 |

0.351 |

0.350 |

0.349 |

0.349 |

|

32 |

142 |

0.515 |

0.495 |

0.476 |

0.466 |

0.462 |

0.460 |

0.459 |

0.458 |

0.458 |

|

34 |

151 |

0.634 |

0.622 |

0.607 |

0.599 |

0.595 |

0.594 |

0.593 |

0.592 |

0.592 |

|

36 |

160 |

0.772 |

0.768 |

0.762 |

0.758 |

0.756 |

0.756 |

0.755 |

0.755 |

0.755 |

|

38 |

169 |

0.930 |

0.934 |

0.942 |

0.947 |

0.949 |

0.950 |

0.951 |

0.951 |

0.951 |

|

40 |

178 |

1.11 |

1.12 |

1.15 |

1.17 |

1.18 |

1.18 |

1.18 |

1.18 |

1.18 |

|

42 |

187 |

1.32 |

1.33 |

1.38 |

1.42 |

1.44 |

1.45 |

1.46 |

1.46 |

1.46 |

|

44 |

196 |

1.56 |

1.56 |

1.64 |

1.71 |

1.75 |

1.77 |

1.78 |

1.78 |

1.78 |

|

46 |

205 |

1.84 |

1.83 |

1.94 |

2.04 |

2.10 |

2.14 |

2.15 |

2.16 |

2.16 |

|

48 |

214 |

2.16 |

2.12 |

2.26 |

2.41 |

2.51 |

2.56 |

2.58 |

2.59 |

2.60 |

|

50 |

222 |

2.53 |

2.45 |

2.61 |

2.82 |

2.96 |

3.03 |

3.07 |

3.09 |

3.10 |

|

52 |

231 |

2.95 |

2.82 |

3.01 |

3.27 |

3.47 |

3.58 |

3.63 |

3.66 |

3.68 |

|

54 |

240 |

3.43 |

3.23 |

3.43 |

3.77 |

4.03 |

4.18 |

4.27 |

4.31 |

4.33 |

|

56 |

249 |

3.98 |

3.70 |

3.90 |

4.31 |

4.65 |

4.86 |

4.98 |

5.04 |

5.07 |

|

58 |

258 |

4.59 |

4.22 |

4.42 |

4.90 |

5.34 |

5.62 |

5.78 |

5.86 |

5.90 |

|

60 |

267 |

5.28 |

4.80 |

4.99 |

5.54 |

6.08 |

6.45 |

6.66 |

6.78 |

6.84 |

|

62 |

276 |

6.06 |

5.45 |

5.61 |

6.23 |

6.89 |

7.36 |

7.64 |

7.80 |

7.88 |

|

64 |

285 |

6.92 |

6.18 |

6.29 |

6.98 |

7.76 |

8.36 |

8.72 |

8.93 |

9.04 |

|

66 |

294 |

7.89 |

6.98 |

7.05 |

7.78 |

8.70 |

9.44 |

9.91 |

10.18 |

10.33 |

|

68 |

302 |

8.96 |

7.88 |

7.87 |

8.66 |

9.71 |

10.61 |

11.20 |

11.55 |

11.75 |

|

70 |

311 |

10.2 |

8.9 |

8.8 |

9.6 |

10.8 |

11.9 |

12.6 |

13.1 |

13.3 |

|

72 |

320 |

11.5 |

10.0 |

9.8 |

10.6 |

12.0 |

13.2 |

14.1 |

14.7 |

15.0 |

|

74 |

329 |

12.9 |

11.2 |

10.9 |

11.7 |

13.2 |

14.7 |

15.8 |

16.5 |

16.9 |

|

76 |

338 |

14.5 |

12.5 |

12.1 |

12.9 |

14.5 |

16.2 |

17.5 |

18.4 |

18.9 |

|

78 |

347 |

16.2 |

13.9 |

13.4 |

14.2 |

15.9 |

17.8 |

19.4 |

20.5 |

21.1 |

|

80 |

356 |

18.2 |

15.5 |

14.8 |

15.6 |

17.4 |

19.6 |

21.4 |

22.7 |

23.5 |

|

82 |

365 |

20.2 |

17.2 |

16.4 |

17.2 |

19.1 |

21.4 |

23.5 |

25.1 |

26.1 |

|

84 |

374 |

22.5 |

19.1 |

18.1 |

18.8 |

20.8 |

23.4 |

25.8 |

27.6 |

28.8 |

|

86 |

383 |

25.0 |

21.2 |

19.9 |

20.6 |

22.6 |

25.5 |

28.2 |

30.4 |

31.8 |

|

88 |

391 |

27.6 |

23.4 |

21.9 |

22.5 |

24.6 |

27.7 |

30.7 |

33.2 |

35.0 |

|

90 |

400 |

30.5 |

25.8 |

24.1 |

24.6 |

26.8 |

30.0 |

33.4 |

36.3 |

38.3 |

|

Conversion: 1 in = 25.4 mm. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

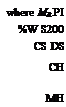

Analysis period =_____ 20____ years

Assumed SN or D =_____ 9_____ in

|

Current |

Growth |

Design |

ESAL |

Design |

|

|

Vehicle types |

traffic (A) |

factors (B) |

traffic (C) |

factor (D) |

ESAL (E) |

|

2% |

|||||

|

Passenger cars |

5,925 |

24.30 |

52,551,787 |

0.0008 |

42,041 |

|

Buses |

35 |

24.30 |

310,433 |

0.6806 |

211,280 |

|

Panel and pickup trucks |

1,135 |

24.30 |

10,066,882 |

0.0122 |

122,816 |

|

Other 2-axle/4-tire trucks |

3 |

24.30 |

26,609 |

0.0052 |

138 |

|

2-axle/6-tire trucks |

372 |

24.30 |

3,299,454 |

0.1890 |

623,597 |

|

3 or more axle trucks All single-unit trucks |

34 |

24.30 |

301,563 |

0.1303 |

39,294 |

|

3-axle tractor semitrailers |

19 |

24.30 |

168,521 |

0.8646 |

145,703 |

|

4-axle tractor semitrailers |

49 |

24.30 |

434,606 |

0.6560 |

285,101 |

|

5+ axle tractor semitrailers All tractor semitrailers |

1,880 |

24.30 |

16,674,660 |

2.3719 |

39,550,626 |

|

5-axle double trailers |

103 |

24.30 |

913,559 |

2.3187 |

2,118,268 |

|

6+ axle double trailers All double trailer combos |

0 |

24.30 |

|||

|

3-axle truck-trailers |

208 |

24.30 |

1,844,856 |

0.0152 |

28,042 |

|

4-axle truck-trailers |

305 |

24.30 |

2,705,198 |

0.0152 |

41,119 |

|

5+ axle truck-trailers All truck-trailer combos |

125 |

24.30 |

1,108,688 |

0.5317 |

589,489 |

|

All vehicles |

10,193 |

90,406,816 |

Design ESAL |

43,772,314 |

|

Location |

|

Example 1 |

|

Source: Guide for Design of Pavement Structures, American Association of State Highway and Transportation Officials, Washington, D. C., 1993, with permission. |

|

TABLE 3.21 Equivalency Factors for Determining ESAL

Notes: B = tractor-trucks with semitrailers and trucks with trailers. C = single-unit trucks (2 axles, 6 tires or more). Source: Ohio Department of Transportation, Location and Design Manual, Vol. 1, Roadway Design, December 1990, revised October 1992, with permission. |

|

||

REPEATED LOAD ACTUATOR

REPEATED LOAD ACTUATOR

:SOLID BASES

SECTION VIEW

Note: LVDT tips shall rest on the triaxial cell itself or on a

Note: LVDT tips shall rest on the triaxial cell itself or on a

plate/bracket which is rigidly attached to the tnaxial cell

FIGURE 3.9 Triaxial test chamber for determining resilient modulus of soil specimen. (From NRC Operational Guide No. SHRP-LTPP-OG-004, “SHRP-LTPP Interim Guide for Laboratory Material Handling and Testing," with permission)

Leave a reply