Rehabilitation of Flexible Structures

Flexible metal pipes may need rehabilitation wherever there is a loss of section or where large deflections (greater than 5 percent) are present. Where the culvert has

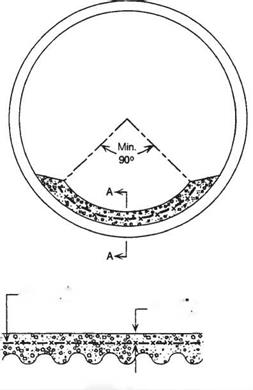

undergone a loss of its structural section due to corrosion or erosion, the amount of loss should be noted and a determination made whether the culvert needs to be strengthened or only protected. The loss of section in metal culverts usually occurs at the invert due to the abrasive conditions of the water flow and/or the corrosive effects of the water. If the loss of section is not significant, it may be adequate to protect the invert with a coating to prevent future erosion or corrosion. The reason for the loss of section should be determined. If the loss is due to corrosion, the application of an asphalt paved invert material should provide protection against future corrosion. However, the asphalt coating does not withstand abrasion well. If the loss is due to erosion, paving the lower quadrant with portland cement concrete will be adequate. Either of these methods is applicable as long as there is no significant loss of structural section that would reduce the structural capacity of the culvert. Where the loss of section is considerable, the structural integrity may be maintained by the addition of welded wire fabric to the concrete paving of the invert. The wire mesh may be welded to the invert corrugations of the metal culvert and then the portland cement concrete placed to provide a smooth channel for the water. Figure 5.47 illustrates rehabilitation with concrete paving. Should the culvert have major structural defects, it may be necessary to replace or reline it or place reinforced concrete around the complete periphery.

Welded wire

Welded wire

over reinforcement

Section A-A

FIGURE 5.47 Example of invert paving of metal culverts with reinforced concrete. (From Highway Design Manual, California Department of Transportation, with permission)

Leave a reply