Median Barrier End Treatments

Median barriers, similar to roadside barriers, should be introduced and terminated with safety in mind. Openings or breaks in barriers should be kept to a minimum to negate the need for end treatments. Where openings are required, shield barrier ends or, if the median

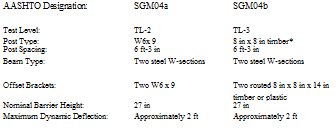

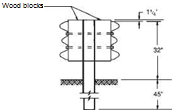

SGM04a (with nonsteel blocks)

|

|

TL-3 W6x9 6ft-3 in Two steel W – sections

Two 6 in x 8 in x 14 in timber or plastic 27 in

|

|

|

|

Approximately 2 ft

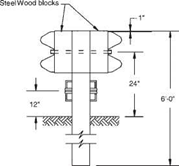

Remarks: These systems are semirigid and are satisfactory for use in narrow medians. After typical impacts, the system remains serviceable. Some states use a W-section as a rubrail, centered at 10 in above grade. This modification is appropriate for both the SGM06a and b, and a higher SGM04a and b. By dividing any of these systems into parallel roadside barriers, assuming adequate deflection distance, fixed objects in the median can be effectively shielded,

*6 in x 8 in post and blockout is acceptable

FIGURE 6.29 W-beam (strong-post) median barrier. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. (From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission) is sufficiently wide, flare or offset the barrier. In locations where impacts are likely, end treatments must be crashworthy. Also, they should safely redirect vehicles impacting from the rear, where hits from opposing traffic are likely. Many proprietary devices are available for terminals. Appropriate end terminals for W-beam barriers include the CAT or Brakemaster. For concrete barriers consider the ADIEM, the TRACC, the QuadGuard™, and the REACT-350®. Sand barriers can also be used to shield median barrier ends, particularly where medians are wide and the likelihood of impacts from opposing traffic is low.

|

SGM09a |

SGM09b |

||

|

AASHTO Designation: |

SGM09a (with non steel |

SGM09b |

SGM09c |

|

blocks) |

|||

|

Test Level: |

TL-3 |

TD4 |

TL-3 |

|

Post Type: |

W6x 9 |

W6x9 |

6 in xSin timber |

|

Post Spacing: |

6 ft-3 in |

6 ft-3 in |

6 ft-3 in |

|

Beam Type: |

Two thrie-beams |

Two thrie-beams |

Two thrie-beams |

|

Offset Brackets: |

Routed 6 in x 8 in timber |

M14in x 17.2 in steel |

6 in x8in timber or |

|

or plastic |

plastic |

||

|

Nominal Barrier Height: |

32 in |

32 in |

32 in |

|

Maximum Dynamic Deflection: |

Approximately 20 in |

Approximately 20 in |

Approximately 20 in |

|

Remarks; SGM09 systems are satisfactory for use in narrow medians. Normal impacts do little damage to the rail. Under severe impact conditions, the rail of an SGM09b system remains upright and has the capability to redirect 40,000-lb vehicles impacting at 50 mph and at an angle of і 5 degrees. |

|

|

FIGURE 6.30 Thrie-beam (strong-post) median barrier. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. (From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission)

Leave a reply