Jointed Rigid Pavement Distress—Visual Rating

Jointed rigid pavement deterioration is exhibited in any combination of the following distresses:

Surface Deterioration. Surface deterioration (Fig. 3.22) is the result of loss of cement at the surface of the slab (scaling). It is generally caused by excessive surface water and finishing practice, or the loss of both small aggregates and cement caused by abrasion from tires. Surface deterioration affects the noise level of a pavement and cannot be repaired. Surface deterioration by itself is generally of little concern.

|

TABLE 3.26 Pavement Coefficients for Flexible Section Design, Louisiana

*Refer to the following footnotes for strength designations. See the AASHTO guide referenced below for further details. ^Marshall stability number. *Texas triaxial values. §Compressive strength, lb/in2 (1 lb/in2 = 6.895 X 10—3 MPa) Source: Interim Guide for Design of Pavement Structures, American Association of State Highway and Transportation Officials, Washington, D. C., 1972 (rev. 1981), with permission. |

|

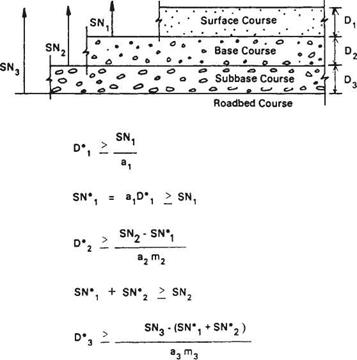

FIGURE 3.21 Procedure for determining thicknesses of layers using a layered analysis approach. a, D, m, and SN are defined in the text and are minimum required values. An asterisk indicates that the value actually used is represented; this value must be equal to or greater than the required value. (From Guide for Design of Pavement Structures, American Association of State Highway and Transportation Officials, Washington, D. C., 1993, with permission) |

Popouts. Figure 3.23 shows a typical popout. Popouts are generally due to high steel placement, but also may be the result of poor-quality aggregate, which disintegrates, causing cavities at the surface of the slab. Popouts affect the noise level of a pavement and cannot be repaired. Popouts by themselves are generally of little concern.

Pumping. Pumping is defined as the ejection of subbase or subgrade materials from under a pavement through a joint or crack and out onto the pavement and shoulder. The loss of subbase or subgrade material causes loss of support and leads to corner breaks and faulting. The existence of pumping can be determined visually by the presence of soil stains at the joints or cracks on the adjacent shoulder.

Faulting. Faulting is a result of the loss of load transfer across a joint or crack, which causes the slab on one side of the joint or crack to be at a lower elevation than the slab on the other side. Faulting (Fig. 3.24) is generally a result of pumping. Faulting affects the noise level and the smoothness of a pavement. It is generally considered excessive when faulting exceeds 1/4 in (6 mm). Faulting can be corrected by pavement grinding, joint or crack repair, or slab jacking. However, unless load transfer

|

FIGURE 3.22 Example of surface deterioration in jointed rigid pavement. |

|

|

|

FIGURE 3.24 Example of faulting at joint in rigid pavement; pavement on right is about 1/2 in (13 mm) lower than that on left. |

is established across the joint or crack and any existing voids under the joint or crack are filled, faulting can be expected to return.

Settlement. Settlement is the result of poor construction practice. It may be due to either poor compaction over a utility, poor grade control during the final grading of the subgrade, or possible localized soil conditions that cannot resist additional overburden or increased loading. Settlement, which is displayed by a depression in the profile of the pavement, affects smoothness. Repair methods consist of replacement to the corrected profile, or an overlay of some type. Settlements are generally of little concern unless they are numerous and severely affect the ride of the pavement.

Joint Spalling. Figure 3.25 shows typical joint spalling, defined as deterioration of the concrete slab around transverse or longitudinal joints. The deterioration is generally only to partial depth and is visible from the surface of the slab. Joint spalling may result from poor-quality aggregates (D cracking); improperly placed dowels, tie-bars, or dowel baskets; or excessive expansion of the concrete (pressure). Repair of spalled joints can be accomplished by either partial-depth joint repairs or full-depth joint repairs.

|

FIGURE 3.25 Example of joint spalling in rigid pavement. |

Trans-verse Cracking. A significant transverse crack is depicted in Fig. 3.26.

Transverse cracking severity varies from hairline cracks to cracks sufficiently wide to completely separate the slab into two distinct pieces. Hairline cracks are expected in reinforced concrete and pose no expected problems. In plain concrete pavement, a hairline crack can be a sign of future problems. Without reinforcing mesh to hold the crack together, the long-term performance of the slab is questionable; however, as long as the crack is tightly closed (hairline), it poses no problem. Regardless of

|

|

|

FIGURE 3.27 Example of longitudinal crack in jointed rigid pavement. |

whether the pavement contains mesh, cracks that have separated by a distance greater than one-half of the largest aggregate diameter are generally considered to be failed.

Longitudinal Cracking. Longitudinal cracking, such as shown in Fig. 3.27, may be caused by excessive lane widths, longitudinal joints that were not sawed properly, or local conditions that increase the stress level along the pavement. Longitudinal cracking is primarily a concern when it occurs within the wheel track. Where a longitudinal crack is faulted, spalled, pumping, or working and is in the wheel path, it can become a safety hazard.

Corner Breaks. As illustrated in Fig. 3.28, corner breaks are cracks found at the corner of the slab. They usually propagate from the transverse joint to the longitudinal joint. Corner breaks are full-depth cracks and are generally the result of loss of support under the corner of the slab.

Leave a reply