INSPECTION

Many storm drains and highway culvert systems have in the past been and are presently designed for a 50-year life span. The local roadway and state highway and interstate systems have in large part reached this age or soon will. Consequently, rehabilitation and repair of existing storm sewers and highway drainage culverts are presently requiring more and more attention and resources from the responsible agencies. It is generally less expensive to rehabilitate or repair an existing underground structure than to replace it. In addition, the cost of repair to the facility after a catastrophic failure

greatly exceeds the cost of rehabilitating the structure and preventing that failure. The key, of course, is being able to identify those structures that are in jeopardy of failing.

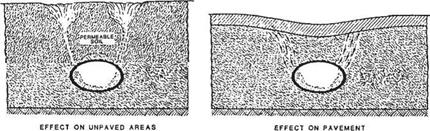

Failure of a culvert can be defined as any condition that could reasonably lead to the collapse of the roadway above or the inability of the culvert to carry the design flow. Failure of the roadway above may be a direct result of the collapse of the structure, or may be caused by a loss of the fill due to piping and the infiltration of fines. Excessive seepage through open joints can cause loss of the backfill material as illustrated in Fig. 5.45.

Fortunately, the complete collapse of a culvert is a rare occurrence. Culverts that are overstressed, either because of loss of the surrounding soil support or because of overloads, tend to redistribute those stresses in many cases. For example, the loss of support or the effect of excessive live loads may not occur over the complete length of the structure. Consequently, as one section becomes overstressed, it may deflect more than the adjacent sections and transfer loads to those stiffer sections. In addition, underground structures that show distress, such as a concrete pipe that cracks excessively or a flexible pipe that deflects excessively, may reduce the loads upon themselves by the very act of deflecting. For instance, flexible pipe that overdeflects may have a reduced overburden load on it because the complete prism of earth above the structure may not necessarily move downward with the deflection; competent soils will have a tendency to arch over the pipe and support some of the load. The concrete pipe that cracks may form hinges and redistribute loads within the structure; the concrete pipe may now have more of a tendency to act as a flexible structure with reduced moments and increased compression forces. However, this discussion should not give the false impression that structural distress can be ignored. Catastrophic failures have occurred and caused fatalities when vehicles plunged into the void left by the collapse. Large structures with low covers are probably the most susceptible to structural failures and should be evaluated carefully.

Even if complete collapse does not occur, structural distress can affect the adjacent soil and accelerate failure. Piping and infiltration that cause loss of adjacent soil support may proceed at an increasing rate and cause failure of the roadway above. In some cases, enough fill may be lost through piping to create a sinkhole with the structure below showing no signs of severe structural distress.

The National Bridge Inspection Program requires that all structures with span greater than 20 ft (6 m) be inspected every 2 years. That is, all structures with spans

|

|

greater than 20 ft (6000 mm) when measured along the centerline of the roadway are classified as bridges for purposes of inspection. Two important points should be mentioned here. First, the measured distance is along the centerline of the roadway. That means a structural-plate pipe or a reinforced concrete box culvert with a 15-ft (4500-mm) span on a 42° skew will be classified as a bridge for inspection purposes and included in the bridge inspection program, even though the span is 15 ft (4500 mm) for hydraulic and structural design purposes. The second point is that multiple pipes are considered to be a bridge for inspection purposes when the out-to-out distance between the first and last pipes is 20 ft (6000 mm) or greater and there is a maximum of one-half diameter of the smaller pipe between them. For example, two 102-indiameter (2550-mm) pipes separated by 51 in (1290 mm) would qualify as a bridge (102 + 51 + 102 = 255 in, or 21.25 ft, or 6375 mm).

Culverts that do not qualify for inspection under the bridge program should nevertheless be given consideration for inclusion in a regular inspection program. To avoid repetition of inspections, some coordination between the engineers responsible for the two programs is necessary. Although the ideal would be to inspect all culverts, obvious constraints, with regard to both physically inspecting the culverts and the costs of doing so, place limits on any program of culvert inspection. It may be less expensive to replace small culverts that are located beneath lightly traveled roads and have little fill on them than it would be to maintain them in an inspection program with rehabilitation prior to failure as a goal. Conversely, where some culverts may not warrant inspections absent obvious signs of distress, others may require frequent inspections. Large structures that carry high flows during major storms or have a history of structural deficiencies, such as cracking (in concrete) or corrosion (in metal), should be inspected more frequently and especially after periods of storms.

Leave a reply