Inspection of Rigid Structures

Inspection of reinforced concrete pipe should focus on problems with alignment, joints, and the wall.

The alignment of the culvert may be inspected visually. Misalignment may be caused either by poor installation practices or by subsequent settling of the pipe or the backfill. In any case, the pipe should be periodically monitored to ensure that the condition does not worsen. Close inspection of the joints may reveal conditions that will lead to an increase in the misalignment of the structure.

Joints should be inspected for cracks, separation, exfiltration, and infiltration. Cracks and separation of joints are detrimental to the culvert only insofar as they increase the possibility of infiltration and exfiltration. Infiltration is the inflow of water and the accompanying fines during times of high groundwater when the flow in the pipe itself is low. If the inspection is made during this time period and infiltration is occurring, it will be evident. If the inspection is made during a period when high groundwater is not present, but infiltration has occurred, there may be evidence of residual fines and silt at the joints. Infiltration can cause the loss of backfill and eventually lead to a failure of the roadway above as shown in Fig. 5.45.

Exfiltration is the outflow of water from the pipe into the surrounding backfill. This may cause piping, a loss of backfill material carried away by the outflowing water. This can create problems both with the roadway above and with the culvert itself, which can lose structural integrity because of the loss of side support. If exfiltration is occurring, it may be observed when the flow is relatively low by inspection of the joints. In addition, there may be some evidence of piping at the outlet end of the culvert, where undermining and the deposition of fines may be present.

Whereas loss of backfill support would be evidenced by excessive deflection in a flexible culvert, rigid culverts will not exhibit this condition. Despite the loss of backfill support, there may be little or no sign of distress in the wall of the culvert.

The walls of concrete pipe should be inspected for longitudinal and transverse cracks and spalls and wearing of the invert. Longitudinal cracks at the pipe crown or invert (cracks that run lengthwise down the culvert) are indicative of high flexural stresses in the pipe. As the pipe is loaded, it tends to deflect downward and outward. These deflections cause the inside of the pipe at the crown and invert to be in tension as well as the outside of the pipe at the springlines. If the pipe is subjected to a high load, longitudinal cracks may develop at these locations. Because the pipe is buried, inspection of the longitudinal cracks located at the springline on the outside of the pipe is not possible. However, the longitudinal cracks at the crown and the invert will be evident if they exist. Cracks 0.01 in (0.25 mm) or less in width are considered to be hairline cracks and are of minor importance. Larger cracks should be noted and monitored.

Longitudinal cracks located between the crown or invert and the springline are usually caused by shear failure of the wall section. If this type of cracking is visually observed, it is imperative that the cause of the cracking be investigated further. If a shear-type failure is determined to be the cause of the cracking, a rehabilitation or replacement strategy needs to be implemented immediately since the load-carrying capacity of the pipe has been compromised.

|

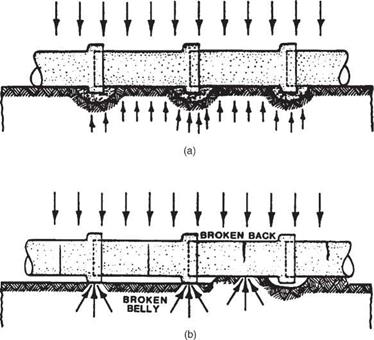

FIGURE 5.46 Illustration of transverse (circumferential) cracking in concrete pipe because of differential settlement. (a) Properly prepared bedding evenly distributes loads. (b) Improperly prepared bedding results in stress concentrations. (From "Culvert Inspection ManualReport No. FHWA-IP-86-2, FHWA, 1986, with permission) |

Transverse cracks (cracks extending around the circumference of the pipe) are caused by differential settlement along the length of the pipe. This can be caused by either unsuitable foundation material or poor installation practices. These cracks are usually not structural in nature but can lead to spalling or subsequent corrosion of the reinforcing steel. Figure 5.46 illustrates transverse cracking resulting from improperly prepared bedding.

Invert wear on a reinforced concrete pipe or box culvert will be indicated by rutting of the surface or rust stains on the surface. In the extreme case, there will be exposed reinforcement. All of these conditions lead to a reduction in the structural adequacy of the culvert. Where the reinforcing is exposed, the bond is broken between it and the concrete and the reinforcing is not able to carry the intended stresses.

Unreinforced concrete pipe, whether cast in place or precast, should be inspected for invert wear and cracking. Because the concrete itself must take the flexural stresses, any reduction in thickness due to abrasive wear is of concern. For that reason, if rutting of the invert is evident, an attempt should be made to determine the amount of loss of section. The culvert should be reanalyzed for its structural capacity using this changed section to determine whether or not rehabilitation or replacement is necessary. If longitudinal cracks are present in unreinforced concrete pipe, the modulus of rupture has been met or exceeded and the flexural capacity of the pipe has been reached. As previously mentioned, only those cracks at the crown and the invert may be easily detected.

(See “Culvert Inspection Manual,” Report No. FHWA-IP-86-2, Federal Highway Administration.)

Leave a reply