General Considerations

The most common materials used are concrete, steel, aluminum, and plastic. The material used may affect the hydraulic capacity of the culvert, as different materials and wall configurations have different entrance loss coefficients and coefficients of roughness. The choice of the material is often controlled by structural and durability considerations.

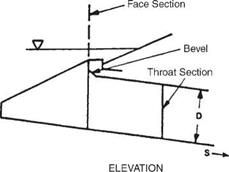

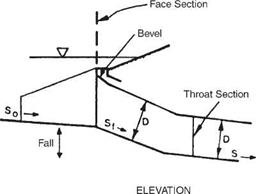

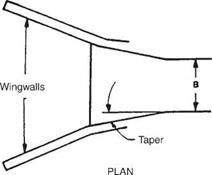

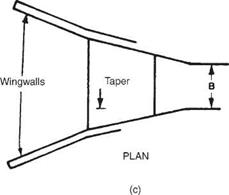

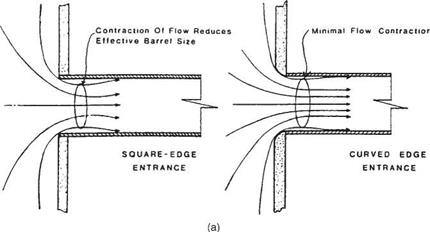

The inlet configuration generally has a direct effect on the hydraulic capacity of the culvert and the backwater upstream from the site. The natural channel approaching the culvert is usually wider than the culvert, and thus the inlet operates as a flow contraction and can be the control for determining the hydraulic capacity. In many instances, the culvert is designed to operate hydraulically with the inlet submerged. This is one advantage that culverts have over bridges, which are designed for freeboard between the high-water elevation and the soffit. If the inlet provides for a gradual transition from the wider natural channel to the narrower culvert barrel, energy losses can be limited. Figure 5.11 depicts some common transitions used to improve culvert hydraulics. Some of the common end treatments used at inlets and outlets include projecting ends, mitered ends, flared ends, and headwalls and wingwalls.

Projecting ends exist when the barrel of the culvert extends out from the face of the embankment. This is probably the least expensive but most hydraulically inefficient of the listed end treatments. It is unsightly, is potentially hazardous to traffic, and can induce scour damage. For these reasons its use should be limited to smaller culverts.

|

|

|

Mitered ends exist where the culvert is formed or manufactured to be in the same plane as the embankment. Mitered ends, when compared with projected ends, are more aesthetically pleasing. However, the projected end is structurally more stable and the mitered end may require the addition of a headwall to compensate for this instability. The hydraulic efficiency of both the mitered and the projected inlets is approximately the same.

Flared ends are generally precast or prefabricated for use with concrete, corrugated steel or aluminum, and plastic pipes. They are used to retain the earth embankment and provide a hydraulic efficiency comparable to that of a headwall.

Headwalls and wingwalls are usually cast-in-place structures. They are designed to retain the embankment, improve hydraulics, prevent erosion, and, in larger-diameter flexible structures, provide support at the inlet and outlet ends. Retaining the earth has an economic benefit for larger structures in that the culvert may be shortened, thereby providing cost savings. The hydraulics may be improved by skewing or warping the wingwalls to provide for a smooth transition between the wider channel and the narrower barrel.

The preferred location of the culvert is in the natural streambed. This alignment usually provides for efficient inlet and outlet configurations and keeps construction costs to a minimum by limiting excavation and backfill work. Aligning the culvert in this manner can result in an inordinately long structure if the natural channel is on a high skew (over 45°) with respect to the roadway. This may be avoided by realigning the channel so that the culvert is placed perpendicular to the highway, but this may lead to erosion and siltation problems. Erosion may occur where the channel is angled to provide for the perpendicular crossing. Siltation may occur as the slope is necessarily reduced because the flow travels a longer distance to traverse the roadway. If a perpendicular culvert crossing is determined to be appropriate, it should be aligned so that the necessary channel realignment occurs downstream of the roadway embankment.

Leave a reply